Periodically, we like to catch up on restoration updates from the workshops at the world-class New England Air Museum (NEAM) in Windsor Locks, Connecticut. Following on from the completion of their remarkable Burnelli CBY-3 blended-wing cargo plane (which we will cover in another article) we have received the following report from restoration crew member, Carl Cruff, concerning the museum’s rare, original Douglas DC-3/C-49.

While many think the DC-3 survives in large numbers, there are actually very few true DC-3s left, as most of what remain are solely ex-military variants of the breed; the most numerous being C-47 Skytrains and, to a lesser extent, C-53 Skytroopers. But NEAM has an airframe which actually began life as a DC-3 airliner for American Airlines. While the aircraft wasn’t complete before the USA entered WWII, it’s construction was already well underway at the Douglas factory in Santa Monica, California by that point, with modifications to the more preferable C-47 configuration being impractical at the time. So when the Army Air Forces impressed her into military service, she became C-49J 43-1973. She served Stateside during WWII, remaining in her passenger configuration, which made it easy for her to slip back into civilian airliner service soon after the military released her in April, 1945. The fabled Eastern Airlines became her first civilian operator when they put her on passenger routes in October, 1945. She passed through several other operators in subsequent years before NEAM acquired her, in November, 1992. By the time of her final flight, she’d accumulated 53,434 in the air!

After a little tidying, the museum displayed her in the condition, more or less, in which she’d arrived for a couple of decades until 2014, when they decided to restore the airframe into a more representative airliner configuration. Externally, she looks pristine now, in her polished aluminum, Eastern Airlines livery, but the restoration has continued internally as well, to bring the fuselage interior back into a period-correct appearance. We shall let Carl Cruff pick up the story from here…

Interior compartment refurbishment continues for NEAM’s DC-3 and the restoration team is enthused to begin build-up and reinstallation activities after many months of teardown and repair actions. A significant milestone passed with the return of the initial upholstered passenger seats which the Redan Upholstery Company completed for us at their facility in Newington, Connecticut. It is appropriate here to acknowledge the John G. Martin Foundation of West Hartford, Connecticut for their continued financial support for the seat upholstery work and the procurement of the ceiling headliner and floor carpeting materials.

Back in the day, the cockpit and adjacent radio/heater bay fuselage walls would have been covered with a quilted fabric insulation material to help reduce engine noise and retain cabin heat. Within our DC-3, however, this covering is either missing, severely deteriorated, or mismatched with several patterns, so it must be replaced in its entirety. Sound Seal, located in Agawam, Massachusetts, is a leading manufacturer of commercial and architectural noise control products and they generously donated several rolls of diamond quilted insulation material for use on the DC-3 and other NEAM restoration projects. Thank you to Marc Sawyer, Project Manager, and the entire Sound Seal team for their support in providing this much-needed material! The fuselage walls in the radio/heater bays are being prepared and painted prior to the installation of the quilted insulation material into the wall and ceiling pockets, while the cockpit walls can be fitted with larger sections.

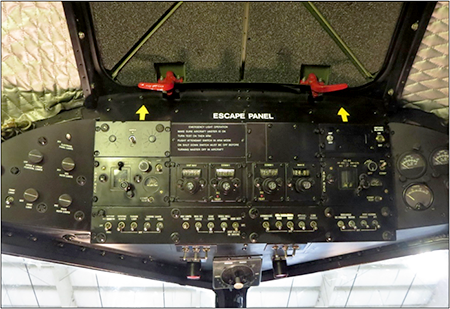

The previously primer-painted left and right cargo compartments have received their top coat paint, and we have installed the cargo restraint netting, which now completes these forward bays. The restoration of the narrow, overhead instrument panel controlling engine start and propeller feathering is now also complete, which finishes the cockpit upper control and instrument panels in the aircraft.

All seven of the single passenger seats are upholstered and returned for fit-check installation. Readers are reminded that we fashioned these single seat frames from existing double seat frames of varying designs to accomplish the desired 21 seat passenger compartment layout of 7 single and 7 double-seat units. The seats are individualized based upon aircraft location and fabrication tolerances requiring a detailed alignment fitting with the seat floor attachment brackets. When this process is completed, we will temporarily remove the seats for floor and wall carpet installation. Several double seats are also now complete, and the team anticipates the return of all double seats by the end of the 4th Quarter.

The passenger compartment headliner configuration involves a forward-to-aft arrangement of multiple narrow and long material strips; the longest, central piece is just over 30 feet in length. To facilitate the attachment of this central piece to the overhead wooden supports, we suspended a temporary scaffold just beneath the desired location. Four restoration team members were then able to support, align, tighten, and staple the headliner piece into position while maintaining a flat and taut surface. We then had to re-establish the light fixture housing locations and cut the fabric at appropriate locations to accommodate these openings. While this installation process was tedious, the team is happy with the resulting appearance.

Following completion of topcoat painting in the lavatory, we began reassembly and reinstallation of various lavatory items. The lavatory door with its interior mirror, the wash sink stand and basin, the fuselage window surround, and the passenger occupant utility panel underwent fit-checking and preparation prior to the headliner and wall covering installation in this compartment.

Many thanks to Carl Cruff and the New England Air Museum for this report. We hope to bring more articles covering this important restoration in the months to come.

Related Articles

Born in Milan, Italy, Moreno moved to the U.S. in 1999 to pursue a career as a commercial pilot. His aviation passion began early, inspired by his uncle, an F-104 Starfighter Crew Chief, and his father, a military traffic controller. Childhood adventures included camping outside military bases and watching planes at Aeroporto Linate. In 1999, he relocated to Atlanta, Georgia, to obtain his commercial pilot license, a move that became permanent. With 24 years in the U.S., he now flies full-time for a Part 91 business aviation company in Atlanta. He is actively involved with the Commemorative Air Force, the D-Day Squadron, and other aviation organizations. He enjoys life with his supportive wife and three wonderful children.

Be the first to comment

Graphic Design, Branding and Aviation Art