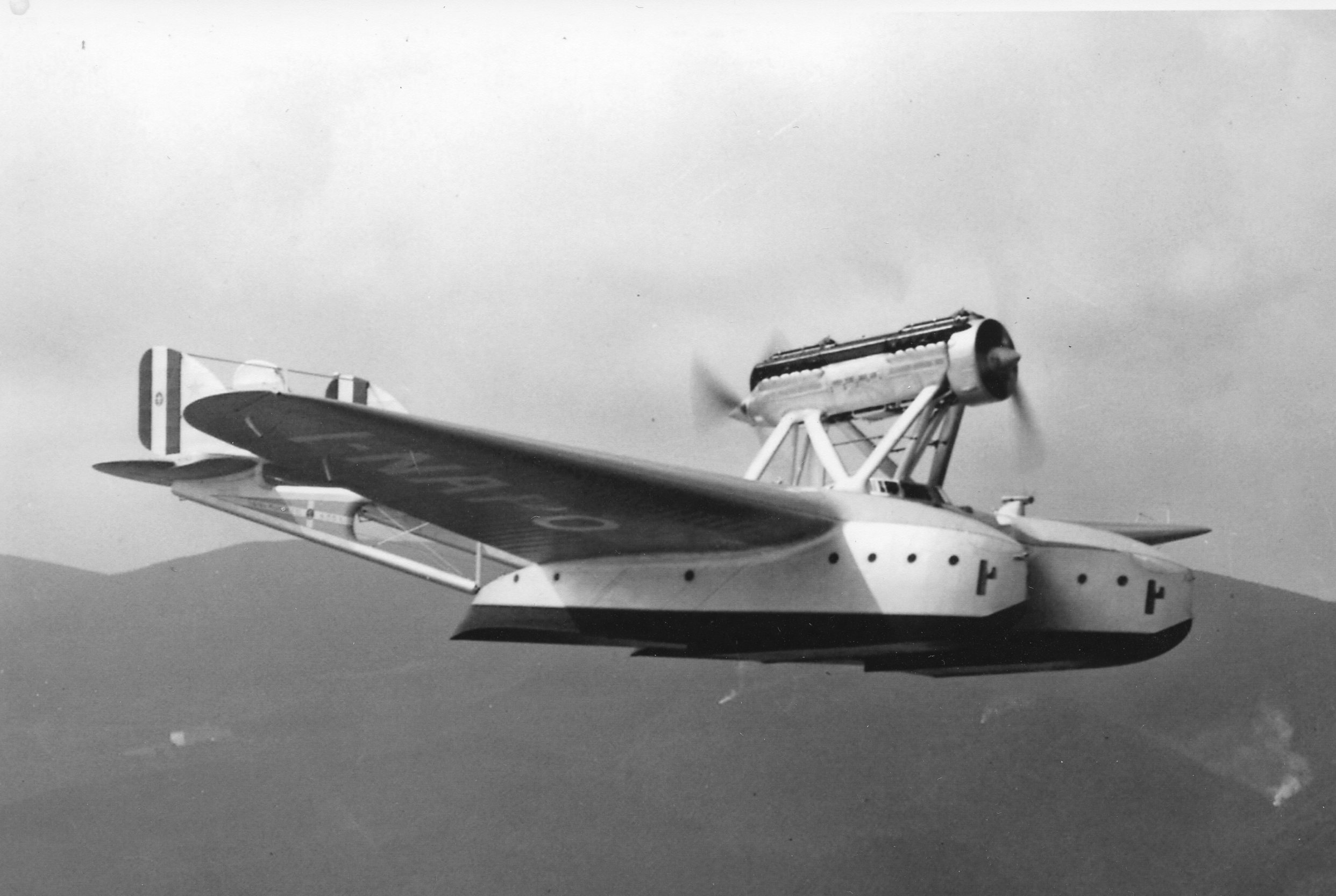

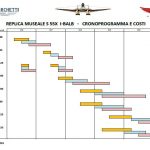

Back in May 2016, we published a story about an ambitious project in Italy to build a static replica of a Savoia-Marchetti S.55, the famous twin-hulled flying boat which broke fourteen long distance, altitude and payload records during the 1920s. Our last update was published in March 2018. Since that time, the volunteers from the Savoia Marchetti Historical Group have made significant progress, so we thought it would be a good time to illustrate their efforts. We have translated a wonderful report by Filippo Meani from the original Italian…

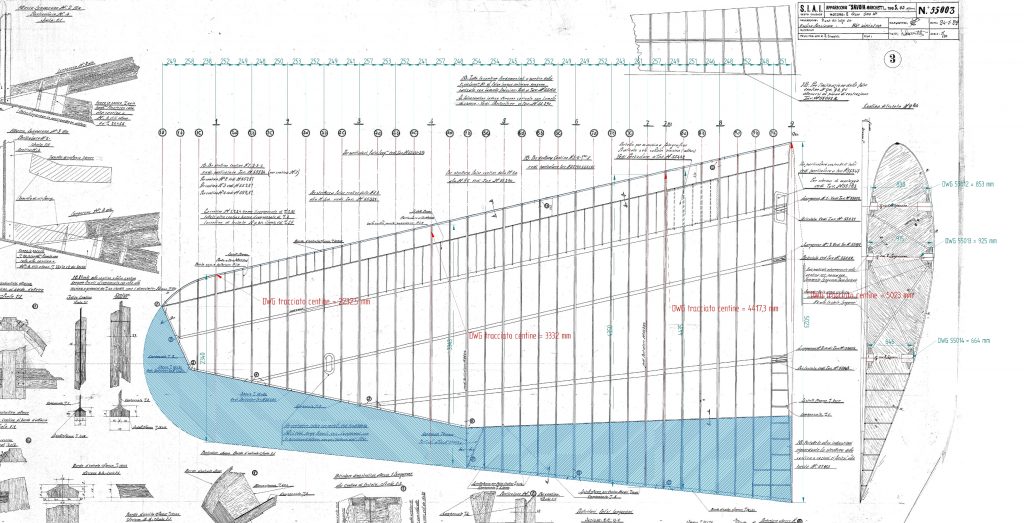

The Savoia-Marchetti S.55 was produced in large numbers for its day; more than 240 examples of all variants became operational. Sadly, only one complete example remains, and it resides in the now-closed TAM museum in São Carlos, Brazil. To redress this issue, the Savoia Marchetti Historical Group set about building a replica based on surviving drawings and photographs. Hopefully a few original parts, such as the engines, will be included too. They chose to focus on recreating the S.55X, a variant which made headlines in 1933 when an entire squadron under the command of Italy’s legendary Air Marshall Italo Balbo made a formation crossing of the Atlantic for a tour of the United States – a magnificent adventure culminating in a 24-ship ‘Balbo’ at the Century of Progress International Exposition in Chicago. While the replica will be complete, the Savoia Marchetti Historical Group has decided to create a cutaway design of the aircraft’s right side to let future generations appreciate the intricate design of its wooden structure.

Engines and propellers

As previously reported, the project team has located two extraordinarily rare Isotta Fraschini L.750 engines from an S.55P which crashed near Khabarosk in Siberia during 1935. Last year, the restoration team began negotiating with the Russian government for their release. Transporting them back to Italy by conventional means will likely be prohibitively expensive, but the restoration team is working towards having one of them flown back to Malpensa, Italy via a donated flight aboard a Leonardo Superjet. In the meantime, Gabriele Caccia has 3D-printed components to assemble two replica engines in case the originals cannot be obtained. These beautifully recreated engines are built using high density Ureol. This material is made from polyurethane and epoxy resin saturated with fillers. Ureol is especially popular for constructing industrial master models, where it is valued for its mechanical properties, such as easy machinability, minimal dust production and resistance to distortion, in addition to its acceptance of many filler varieties and most available paints. It is therefore a highly suitable choice for making complicated parts such as those in the Isotta Fraschini L.750 engines.

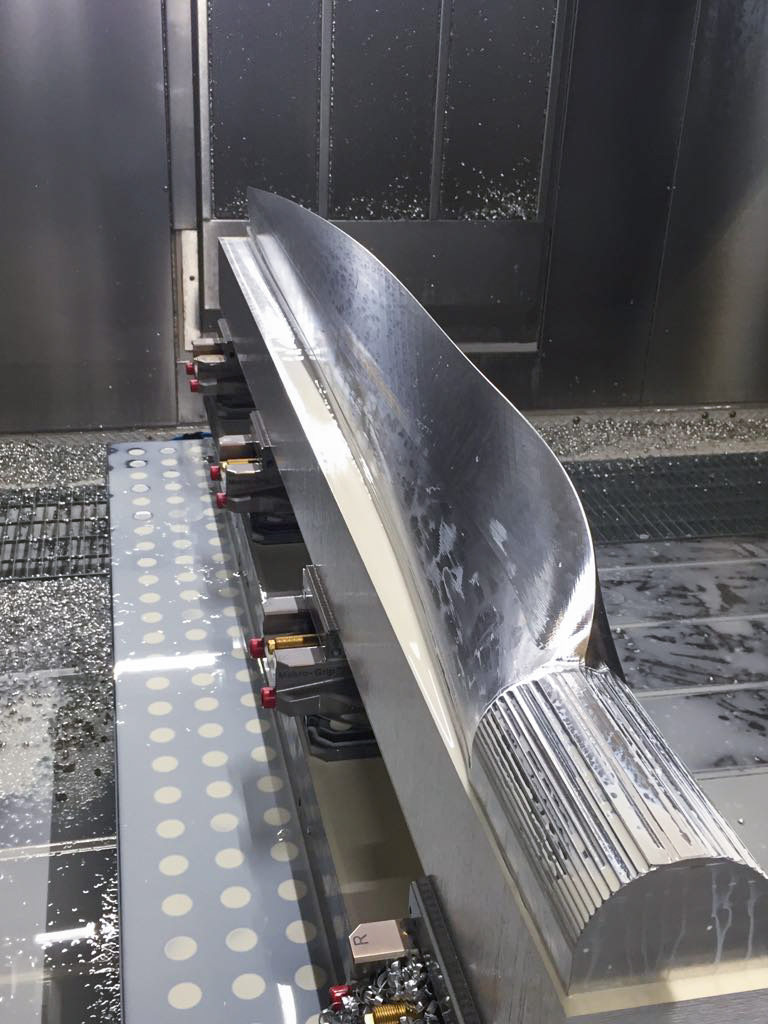

The late Gianluigi Merletti made the propellers using a 5-axis cutter, with aluminum supplied by Marco Monti, owner of the Aviometal company.

The Hulls

The hulls, currently under construction, are a significant manufacturing commitment, not so much for their structural complexity, but rather their significant size, being almost 10 meters (33′) long and more than two meters (6.5′) in width and height. They each weigh more than 700kg (1,570lbs). Perhaps the most exciting news at present is that the first wooden hull is approaching completion.

The Fuselage

Recently the Savoia Marchetti Historical Group have contacted the ASLAM technical college in Lentate sul Seveso. They have excellent machine tools at their disposal, along with skilled students, and as such, they will be able to supply affordable, dimensionally perfect components to accurately recreate the fuselage geometry. This will help ensure that the rest of the aircraft’s many components will fit together properly for the successful completion of the project.

The Wings

The Savoia Marchetti Historical Group is in negotiations with the Italian Air Force’s historical branch which is restoring the Savoi-Marchetti S.79 “Sparrow” that was once on display at the Volandia Museum. The group hopes that, given the similarity of wing construction between the two aircraft, that the Air Force might take on the constructins of the S.55’s outer wings as a learning opportunity prior to building wings for their own project.

So that is as far as things have progressed with the S.55X at present. We look forwards to learning more as the project progresses towards completion. It will be great to one day see a representative example of this remarkable aircraft on display in the nation of its birth!