Chuck Wahl’s Vultures Row Aviation serves as a sanctuary for aviation history, where the iconic Vought F4U Corsair is meticulously restored to its former glory. In a recent revealing interview, Chuck shared insights into his intricate restoration projects, offering a glimpse into the challenges, triumphs, and deep connections forged with these legendary warbirds. Chuck Wahl’s Vulture’s Row Aviation has become a mini-production line for a number of exciting Corsair restorations. Read our previous interview with Chuck [CLICK HERE.]

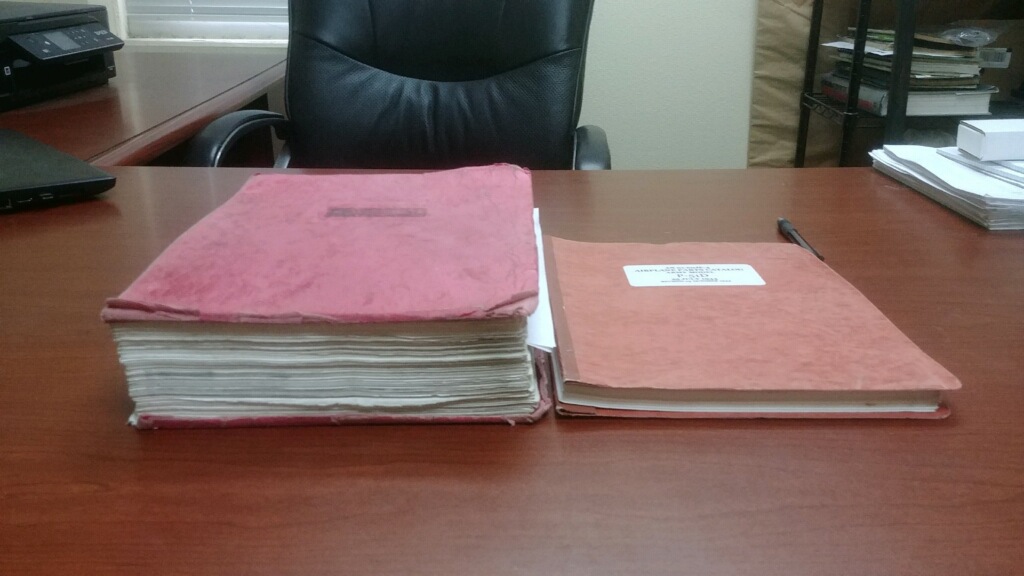

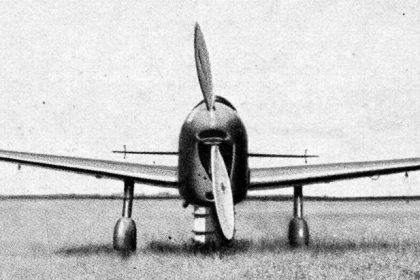

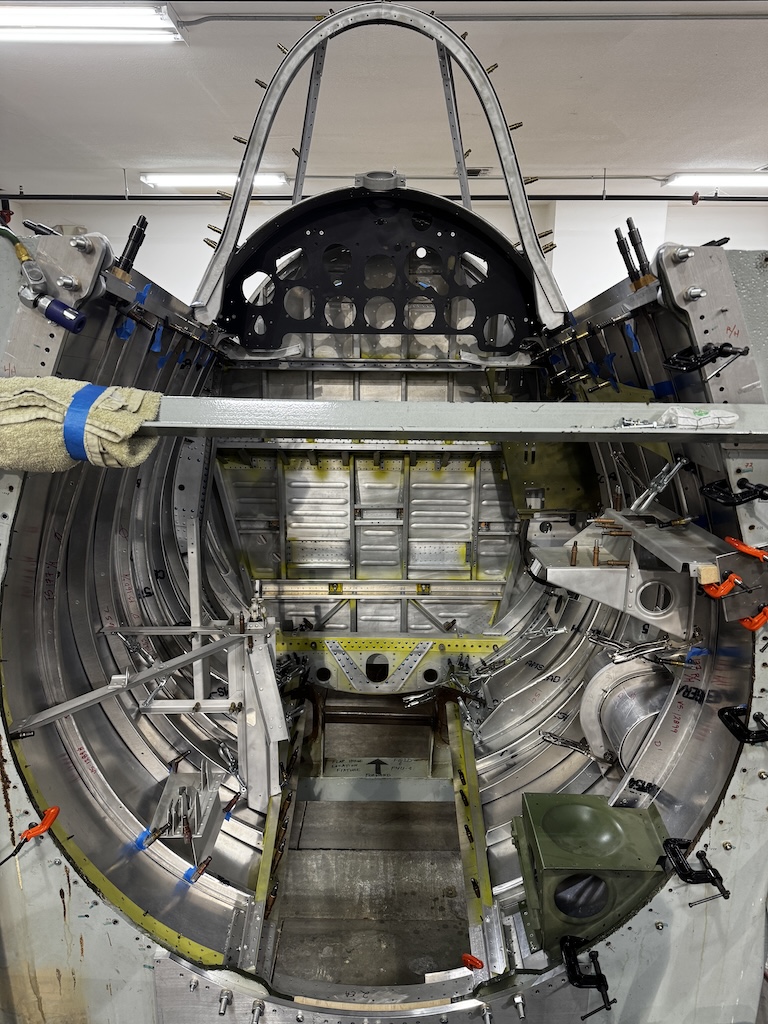

The Birdcage Corsair: A Symphony of Restoration Vought-Sikorsky built Bureau Number 02449, the “Birdcage” Corsair, stands as a testament to Chuck’s dedication. “The Birdcage Corsair restoration is moving along fast and furious,” he says, his excitement and focused determination evident. The tail section, a complex puzzle of ribs, stringers, and skin, is nearing completion, with fairing mounts for the control surfaces just around the corner. The cockpit, a maze of levers, dials, and wires, is distinctly different from later Corsair variants. “There’s a lot of differences in how some of the systems work, like the landing gear and the dive brake,” Chuck explains. The intricate hydraulics, electrical systems, and fuel systems—especially the routing of fuel to the outer wings—pose unique challenges.

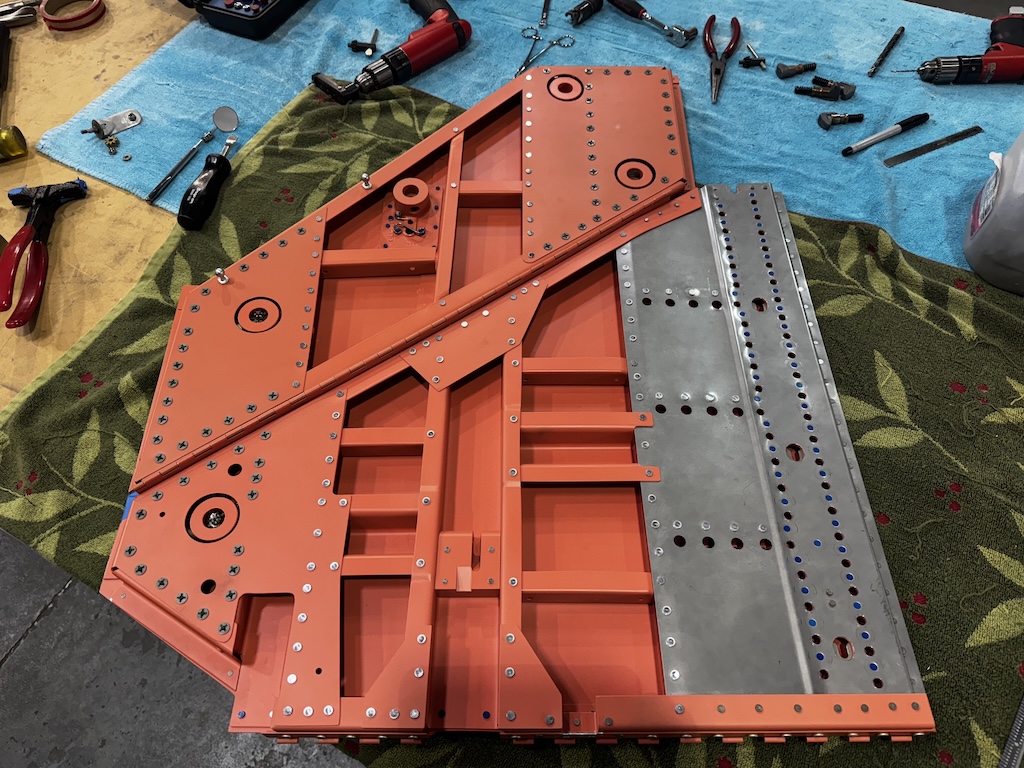

The outer wing panels, essential to the Corsair’s distinctive gull-wing shape, are progressing steadily. “The left-hand leading edge, from the spar forward, is 98% done,” Chuck notes. The complex wet fuel system, carefully sealed and tested, and the intricate gun bay doors are clear signs of the meticulous work underway. “Evan has been working every day on gun bay doors… with great progress there,” he adds.

The next major step is the anticipated mating of the tail section to the tail center section, which will dramatically transform the aircraft’s appearance. However, the installation of the landing gear is the next crucial task. “The tail wheel goes in first, then the main landing gear,” Wahl states, eagerly anticipating the moment when the Corsair will stand on its own wheels for the first time since 1943. “That’ll be the first time it’s been on three wheels since September of 1943. It’s a big day we’re pushing for later this year.”

The final fabric covering and paint, scheduled for 2026, will mark the culmination of years of dedicated effort. “2026 is when the first four wing panels will come out of jigs, ready for fabric and then final paint,” Wahl predicts, his voice filled with anticipation. The Birdcage Corsair’s history is deeply intertwined with Wahl’s own journey. Its arrival at his shop on March 13, 2015, mirrored its departure from Vought-Sikorsky on the same date in 1943. This eerie coincidence, coupled with the aircraft’s wartime service and the tumultuous events surrounding its arrival, has only deepened Chuck’s belief in the aircraft’s “personality.” “These airplanes have personalities, and they talk to you—and spook you sometimes,” he asserts.

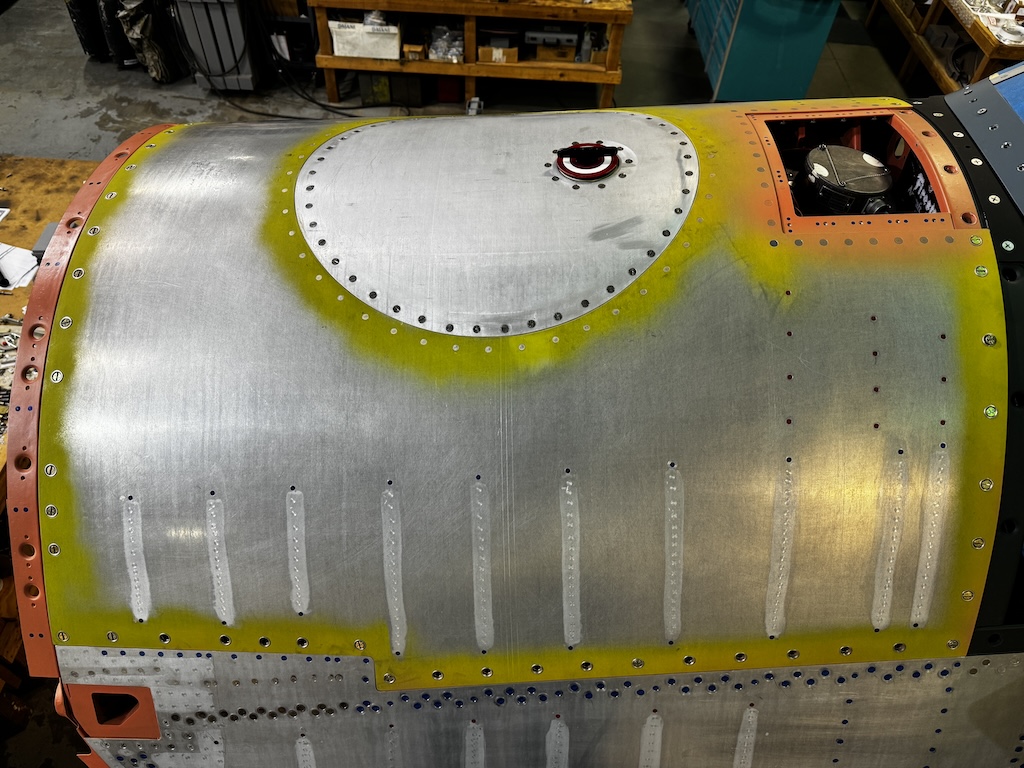

A Fleet of Corsairs: Diverse Projects, Shared Dedication Chuck’s expertise extends far beyond the Birdcage. He has also overseen the restoration of an F4U-4 (Bureau Number 97382), owned by Duane Doyle. This aircraft, with its distinct features and complex systems, is progressing well. “Duane’s in the final-final stages of the gear doors,” Wahl notes, pointing to the intricate work on the compound-curved components. The goal is to have the -4 ready for final flight preparations in late 2025 and progress through 2026 to fly shortly thereafter.

Wahl’s approach to managing these projects is strategic. “We decided to focus on a couple of airplanes at a time instead of all seven at once,” he explains. This method allows for more efficient progress, with sub-components like flaps and landing gear being overhauled in batches. The complexity of Corsair restoration is a recurring theme in Chuck’s narrative. “It’s mind-boggling how many parts there are. Between sheet metal screws and fasteners with nuts and washers, you’ve got almost 500 fasteners for just one outer wing for just installing the fabric,” he exclaims. The sheer volume of parts and the complexity of the systems underscore the challenges faced by restorers.