WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this month!

Fuel Systems

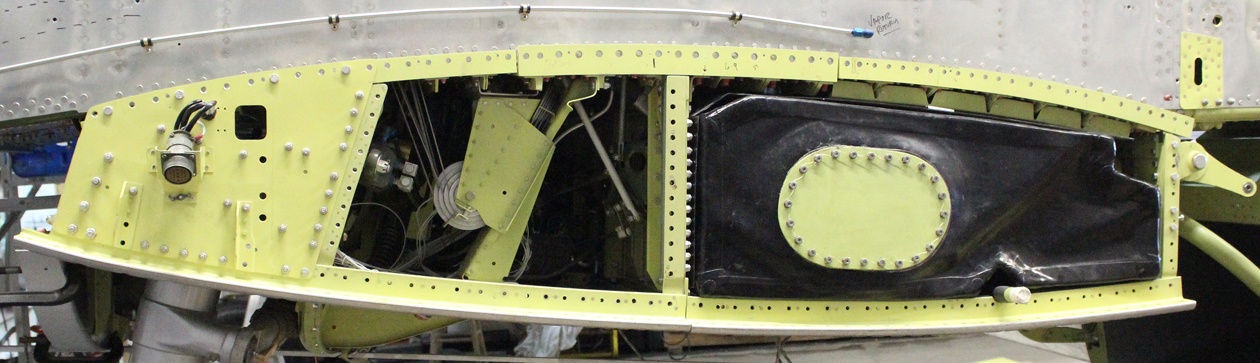

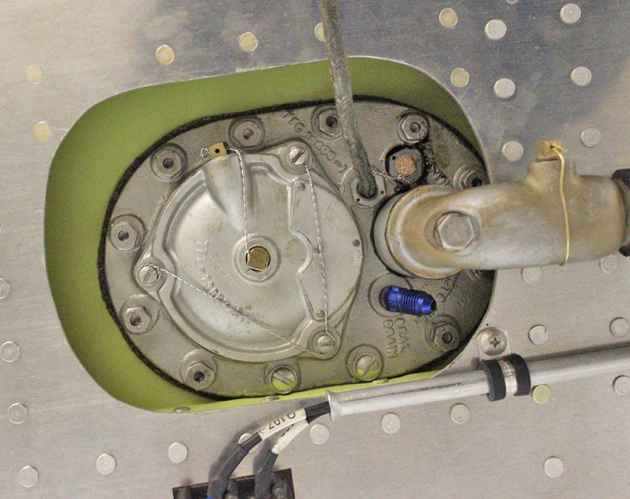

The major job this past month has been installing the wing and center section fuel tanks, boost pumps, liquidometers and sump drains. Reilly’s team completed the installation for the two center section 95-gallon tanks around the first week in January. Three of the four outboard tanks are now installed less their pumps and liquidometers. The team expect to have completed these when the fourth tank is finished in the next week or so.

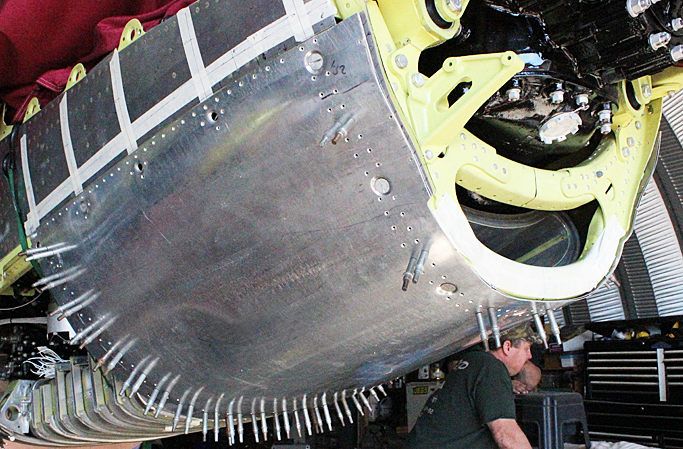

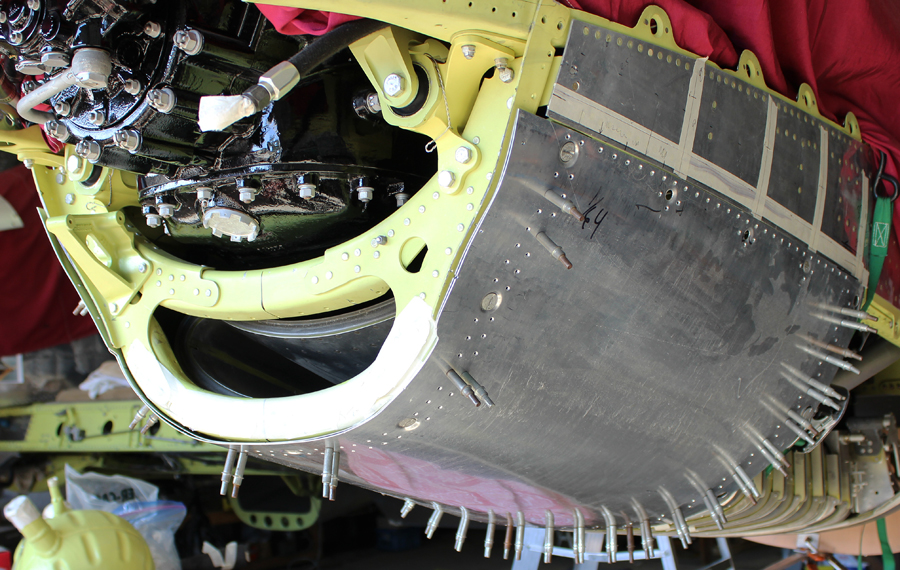

Inboard Gear Doors

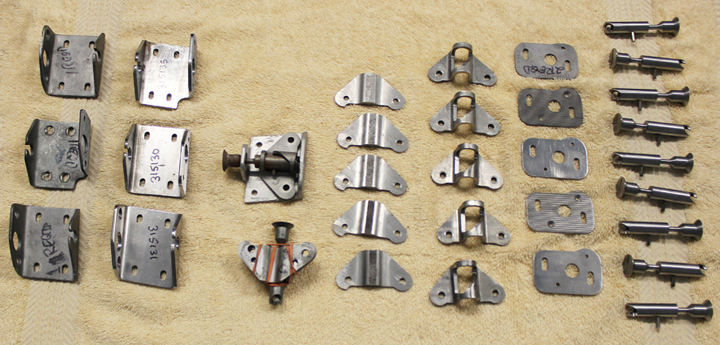

Tom Reilly has been planning the remanufacture of the exceptionally complex-shaped inboard gear doors for several years now. He had recovered two extremely damaged inboard doors from the Alaska wreck site, but neither one had any usable parts. However, the wrecked doors both yielded essential information on how to make new examples. Between these two crashed door remains and the very detailed North American Aviation plans in their possession, two team members were able to complete both door frames in a short amount of time. The press-die pattern for the inside skins is currently under design.

One of Reilly’s contractor machine shops has supplied the project with the four needed gear door hinge points (see below).

Upper & Lower Engine Cowlings

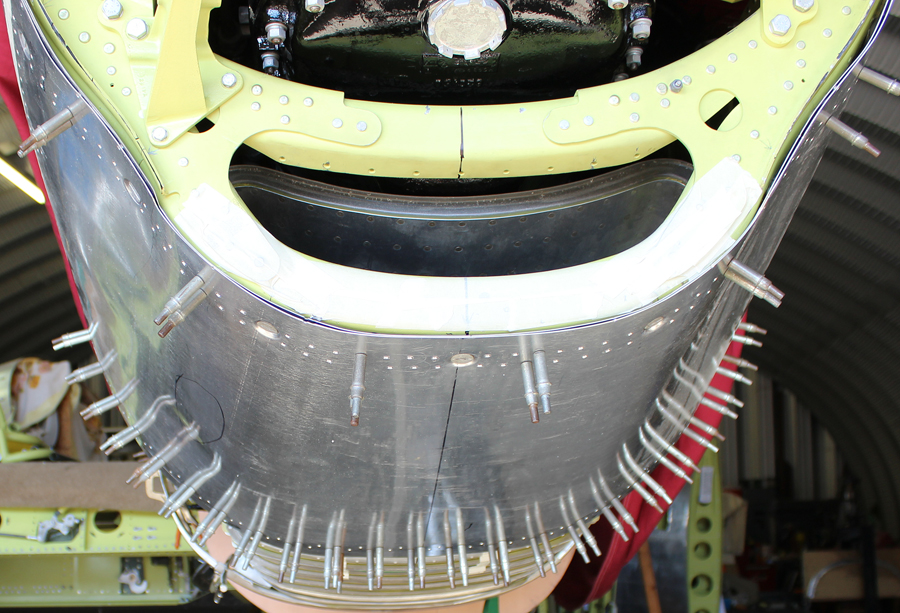

Reilly’s own machine shop finished all of the 4130 alloy steel adjustable-dzus-rail attach points for the left and righthand upper cowlings. These are the attachment fittings that join the two top cowls together down the centerline of the top of each Merlin engine.

With the lower cowling ribs being finished over the past month, the English wheeling of the six (three each engine) lower cowls under way. Within a short amount to time, the team had the first forward, lower wheeled cowl completed. The wheeling of the five remaining cowls should go smoothly. The two filtered-air screen ducts still need to be fitted in the sides of each forward cowl.

Reilly is wistful over how nice it would have been had these cowls been the same as a standard D-model Mustang so that he could have purchased them, more or less off-the-rack, from a current P-51 parts builder, but no such luck!

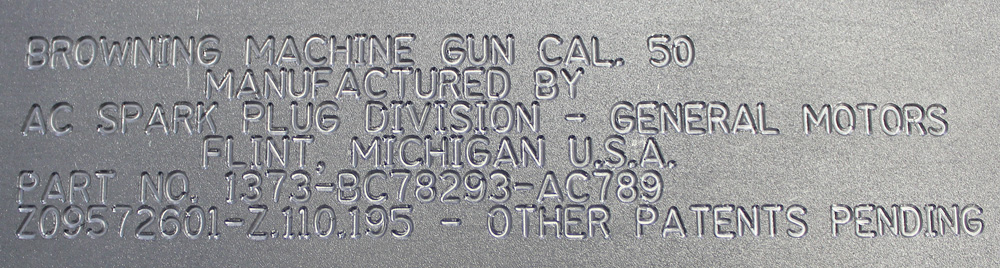

Armament / Replica Machine Guns

The Twin Mustang project received its six replica, dummy machine guns from a contractor. The duplication and detail of all the parts copied from a non-fireable, real .50 caliber gun are superb. All Reilly’s team had to do was paint and re-assemble each weapon, and now begins the process of installing them in the center section gun bays. In an extra flourish of authenticity through a machine gun dealer/friend of his, Reilly was able to locate enough, original, pre-fired WWII .50 caliber shell casings with the correct date code of “44” or “45” stamped on the base.

Rollout Time Frame

Reilly is planning for the XP-82’s first rollout to occur sometime early this summer. The main unfinished task remaining prior to that grand day is the completion and installation of the tail wheel assemblies and retract mechanisms. At that point Mike Nixon’s Vintage V12s (the company that overhauled the XP-82’s engines) will send someone from their base in Tehachapi, California to start both engines and final-test all of the firewall forward systems (fuel, oil, vacuum, hydraulic, propeller, etc., etc.).

Final Major Tasks to Complete

The five major tasks to complete are as follows: the pressing of one, fire-wall-forward dishpan and the two inboard gear door waffle skins, fitting the two outboard gear doors, and then machining and installing the two brake calipers. The final item then will be pressing the parts for and assembling the two air induction trunk forward lip carburetor air control mechanisms; one located under each prop spinner.

—————————————-

And that’s all of the news for January, 2016!

Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in February for the next installment in the story following the XP-82′s road to recovery!

Related Articles

XP-82 Twin Mustang – December 2015 – Restoration Update

XP-82 Twin Mustang – November 2015 – Restoration Update

XP-82 Twin Mustang – October 2015 – Restoration Update

XP-82 Twin Mustang – September 2015 – Restoration Update

XP-82 Twin Mustang – August 2015 – Restoration Update

XP-82 Twin Mustang – July, 2015 – Restoration Update

Richard Mallory Allnutt's aviation passion ignited at the 1974 Farnborough Airshow. Raised in 1970s Britain, he was immersed in WWII aviation lore. Moving to Washington DC, he frequented the Smithsonian’s National Air & Space Museum, meeting aviation legends.

After grad school, Richard worked for Lockheed-Martin but stayed devoted to aviation, volunteering at museums and honing his photography skills. In 2013, he became the founding editor of Warbirds News, now Vintage Aviation News. With around 800 articles written, he focuses on supporting grassroots aviation groups.

Richard values the connections made in the aviation community and is proud to help grow Vintage Aviation News.

The P-82 project at Anoka, Mn. (KANE) is by far ahead of Mr. Riley’s .

The workmanship on C & P Aviation is factory perfect, and about a year out of flight tests. Pat Harker, a low-profile, rebuilder is well known in the Warbird community.

Please put me on the P-82 rebuild status newsletter.

Regards,

Kevin Cogan

Kevon, you can sign up here: http://xp-82twinmustangproject.blogspot.com/p/home_17.html

That XP-82 is in excellent hands. Some of the finest craftsmen are working on it.

Great looking plane. I was there in Harlingen when the CAF’s P-82 landing gear collapsed. that was a sad day.

The workmanship on Pat Harkers F82 is Beond Perfect

Hello Tom Reilly. I love the up dates on your restoration. I am blown away by what you have created and I wait anxiously for the next update. Being a Mustang freak, like many, I am very interested in all things NAA Mustang. My question is: Why don’t we see anything current on the Harker restoration? These restorations are a big deal to a lot of us out here in the world. Any information/photos on restorations is greatly appreciated. Good luck finishing up your XP-82