AirCorps Aviation has established a world-class reputation for the quality of their vintage military aircraft restorations, with numerous award-winning warbirds finding resurrection at their facility in Bemidji, Minnesota. Most of these projects have involved former combat aircraft, of course, but earlier this year, their team began restoring a WWII liaison type, this being Piper L-4H Grasshopper 44-79780. We covered the initiation of this endeavor with Chuck Craven’s detailed first report over the summer, but we are happy to present his most recent update for readers with the following. Enjoy!

Between 1941 and 1945, the USAAF procured 5,413 L-4s for U.S. forces. 1,801 of that number were L-4H variants. Thousands of L-4s remained in the US for the duration of WWII, training pilots and serving liaison duties for Army units in training. The type proved very useful on the civilian market after the war due to its excellent performance, affordability and usefulness in flight training and pleasure-flying roles. As a result, the little Piper ‘L-bird’ is still a common sight in North America. That being said, combat veteran examples are rare in the United States.

L-Birds accompanied the Allied troop advances until the war ended. While many of the fighters and bombers were repatriated to the United States post war, most small planes were decommissioned on the spot. The surviving examples did find use in the post-war era, training thousands of pilots in the former European and Pacific theaters.

Instructions for Army Models L-4A, L-4B, and L-4H, AN 01140DA-1

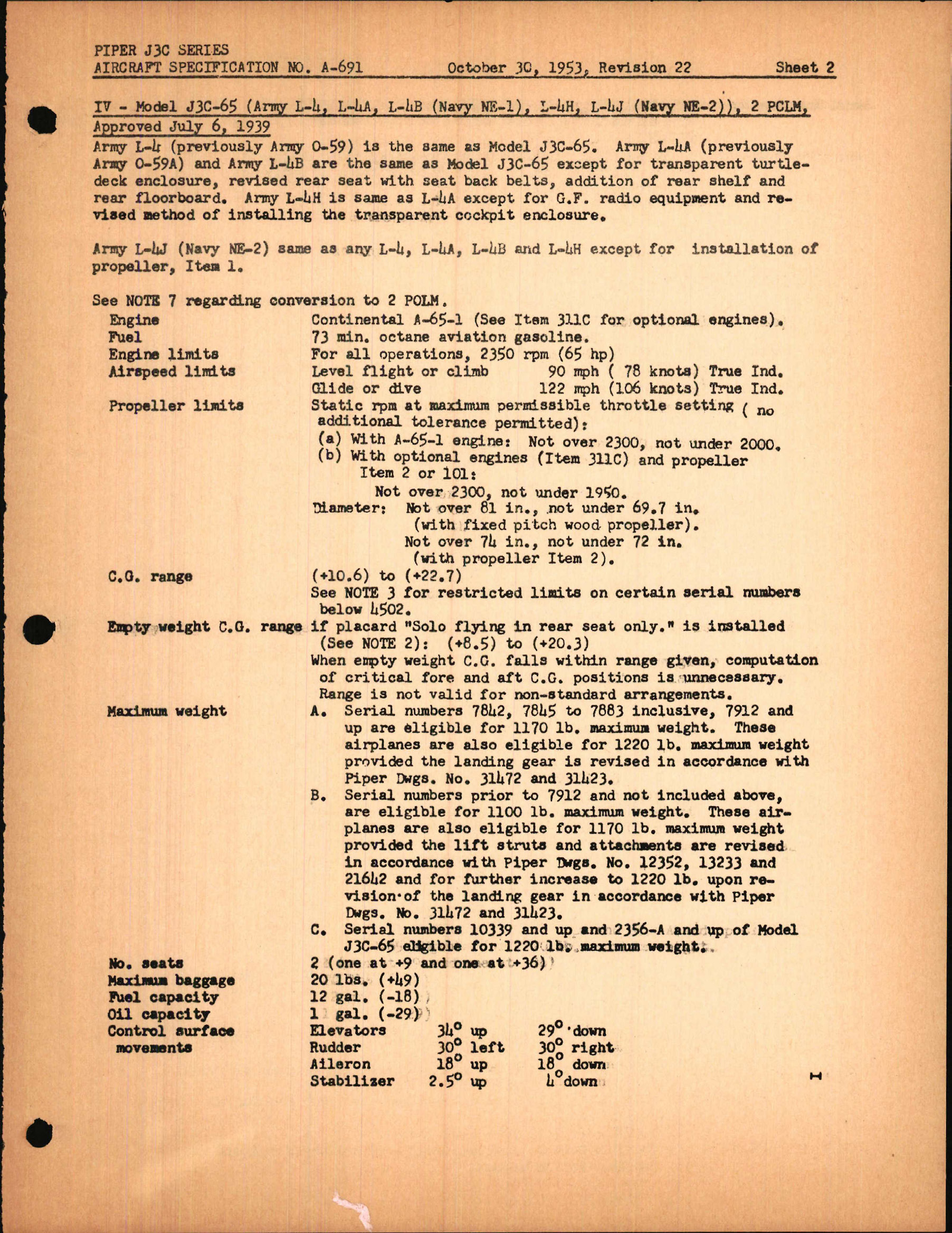

L-4H Specifications:

Overall Length: 22’ 4 1/2”

Wingspan: 35’ 3”

Engine: Continental 0-170-3 (A65-8 civilian) rated 65 hp at 2,250rpm at sea level

Maximum Permissible Engine Overspeed: 2,530 rpm

Fuel Capacity: 12 gal

Fuel Flow: 5.8 gph at take-off (2,300 rpm), 4.27 gph at standard cruise (2,100 rpm)

Empty Weight: 708 lbs, basic weight (includes oil and trapped fuel)

Gross Weight L-4H: 1,220 lbs

Full Load Stall Speed: 37.5 mph

Standard Cruise Speed: 75 mph at 2,150 rpm

Climb at Gross Weight: 300 fpm at 55 mph

Maximum Dive Speed: 122 mph

Take Off Distance From Sod At Sea Level: 352 ft; to clear 50” object, 737 ft

Landing Approach Speed: 60 mph

Landing Distance, Firm Dry Surface: 390 ft; to clear 50” object, 605 ft.

Restoration Progress:

The past weeks have seen the L-4’s wings rebuilt, the wheels and brake parts inspected and restored, and the fuselage tube frame repaired and returned to AirCorp’s restoration shop.

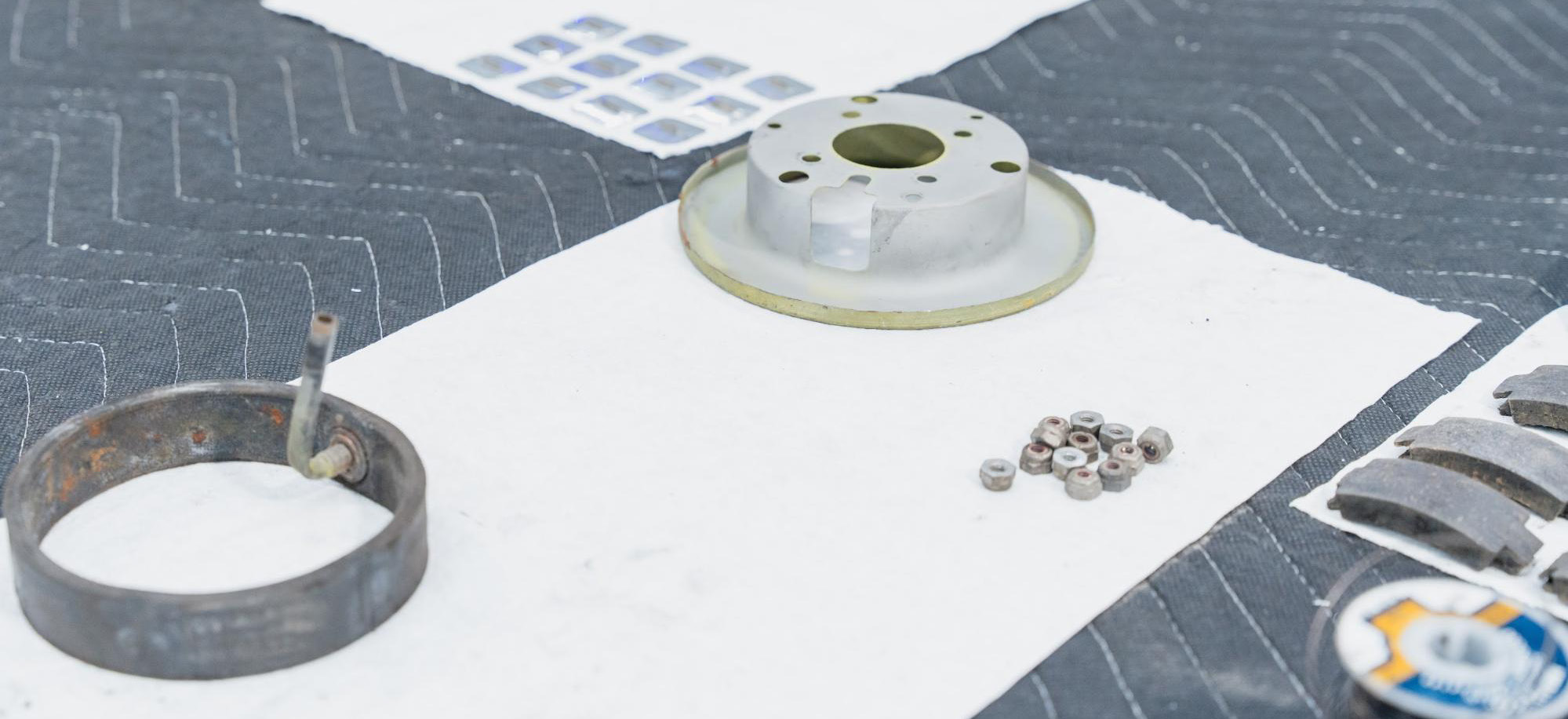

Wheels & Brakes

The L-4B and L-4H variants are nearly identical to one another. A primary difference between the two is the brake system manufacturer. L-4Bs came with Goodrich brakes while L-4Hs used a Scott system. The L-4’s original expander-tube brake system is quite simple. Pressure on the wheel brake lever pushes against a diaphragm which, in turn, forces fluid in the brake line to inflate the expander-tube, which pushes the brake pads against the brake drum.

The original L-4/J-3 brakes aren’t very effective, which can be an advantage in a Cub, because the type requires almost no brake use in typical operations. With expander-tube brakes, it is difficult to brake sufficiently to pick up the tail.

With more effective, replacement brake systems are powerful enough to make a brake-induced nose over a real possibility. Current L-4/J-3 Cub owners are not inexperienced cadets, so they often choose to accept the nose-over risk and retrofit their airplanes with Grove disc brakes under an FAA-approved Supplemental Type Certificate. That is the case with 44-79780.

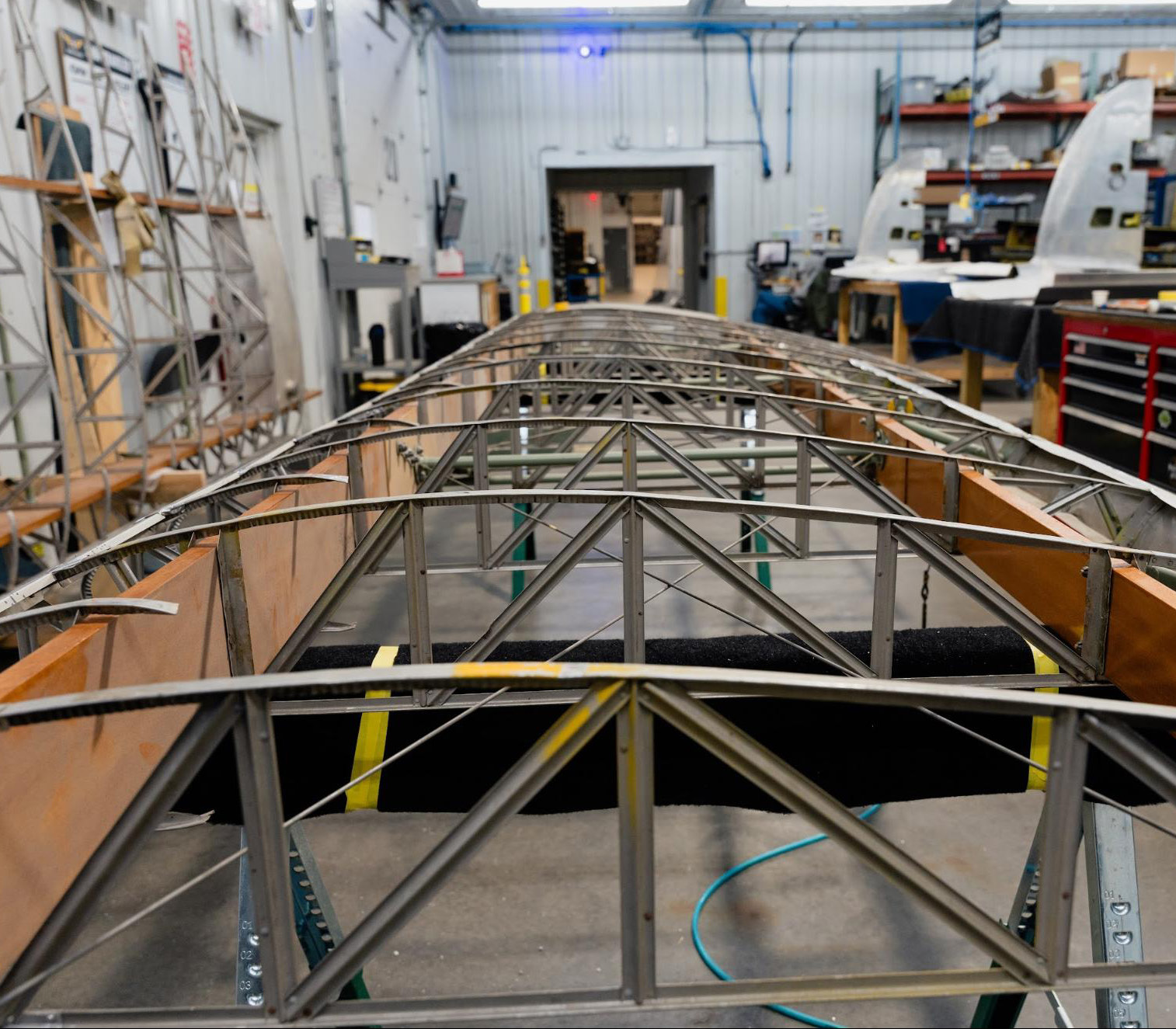

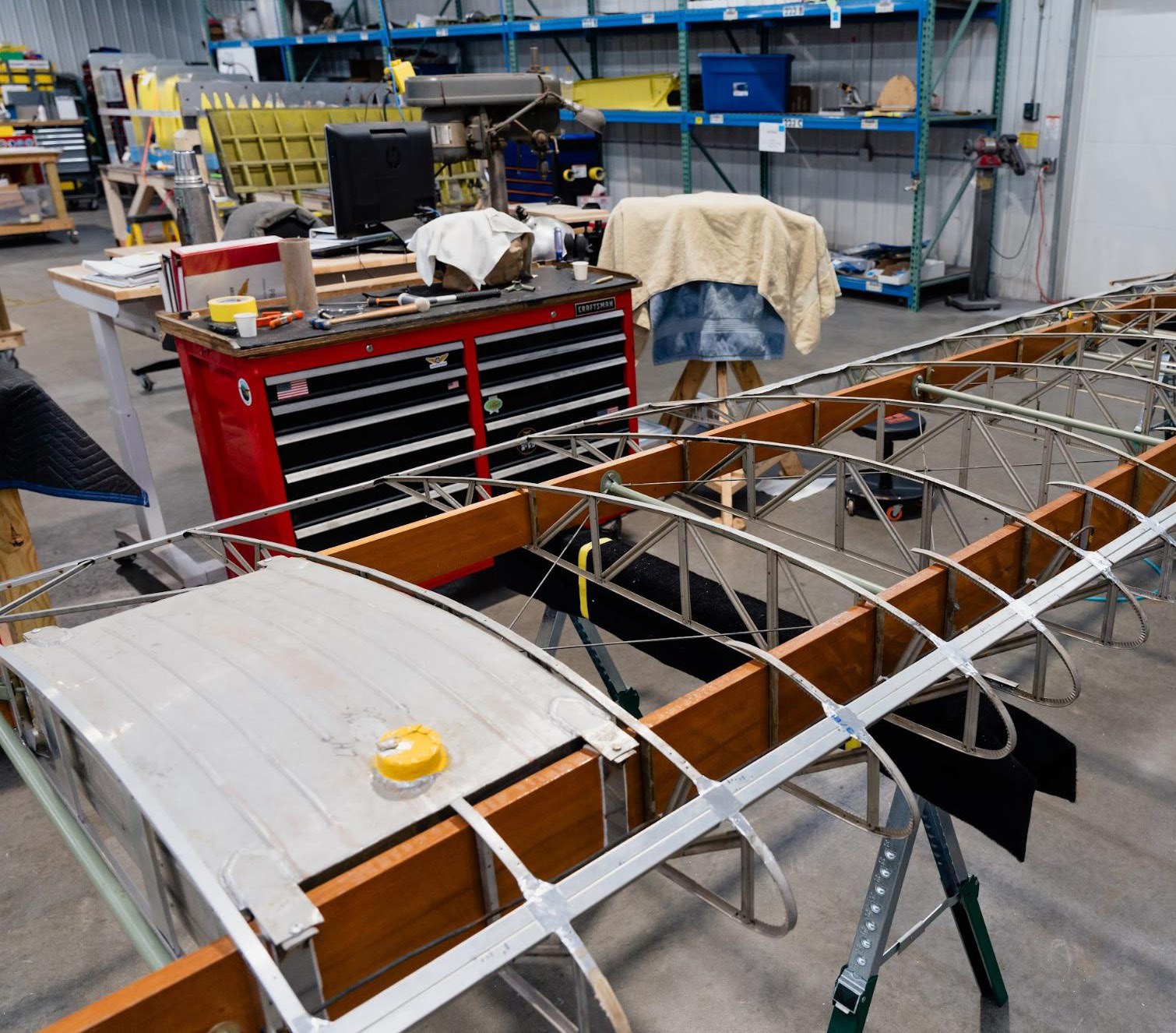

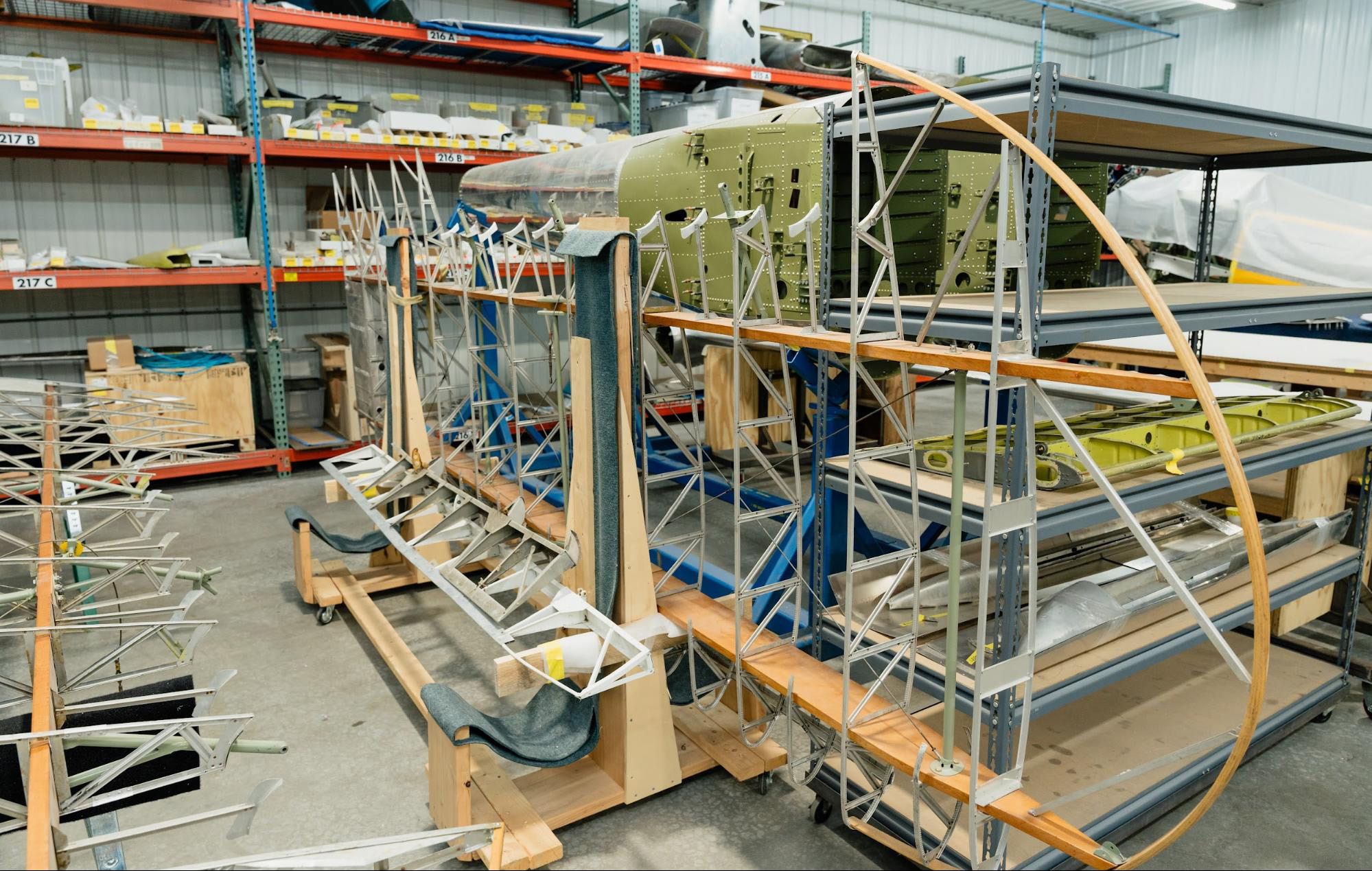

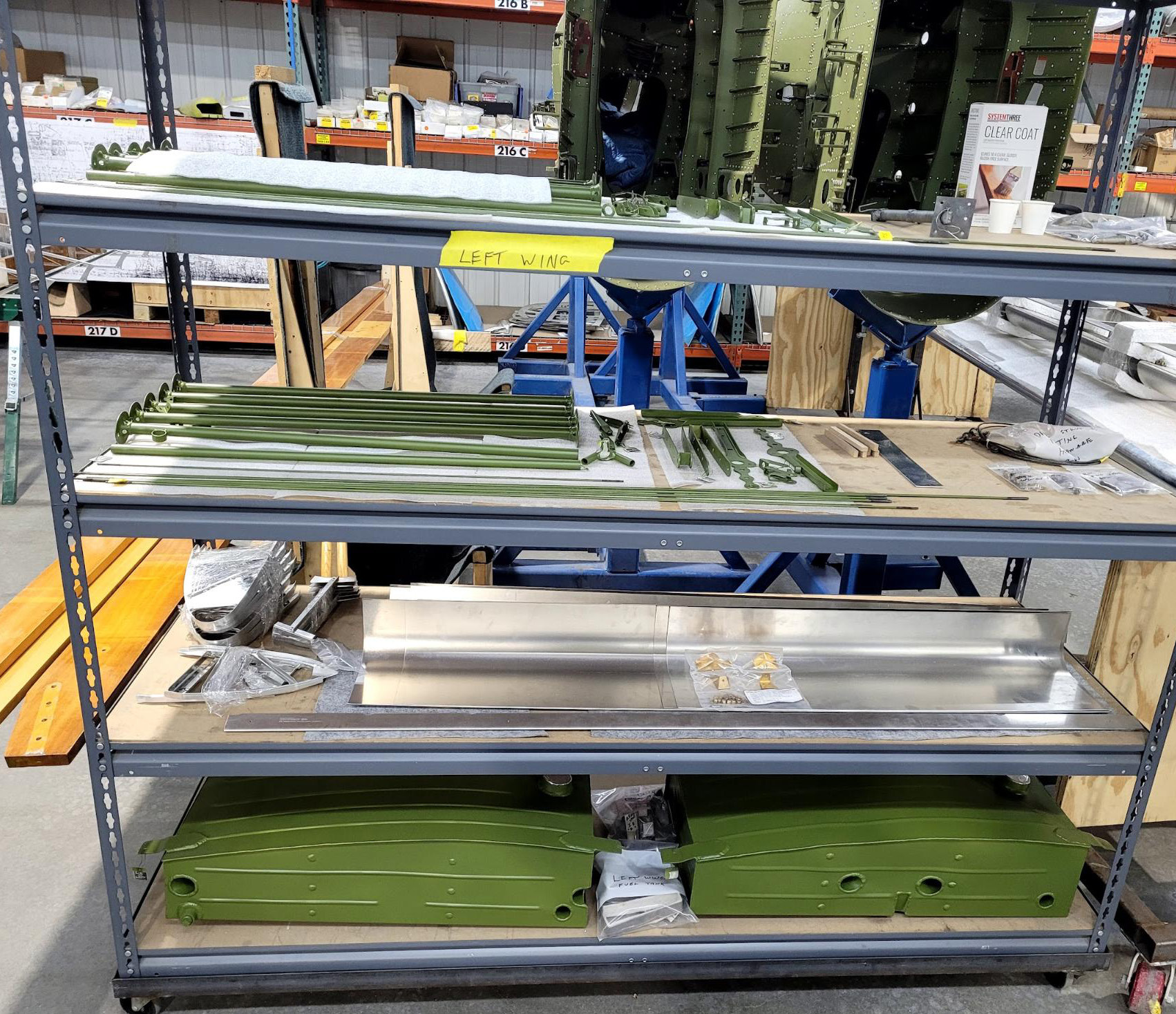

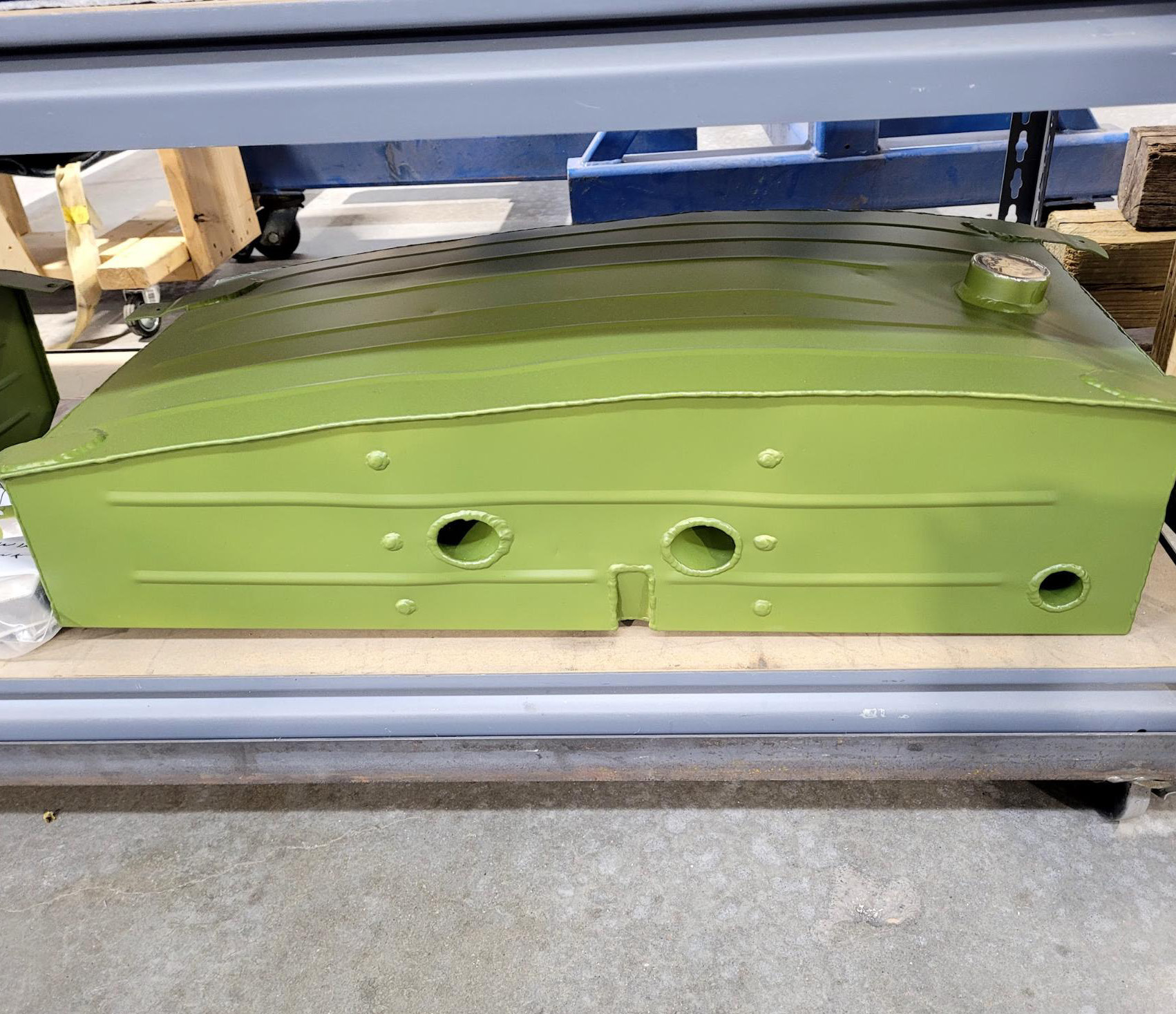

Wings

The L-4’s original wings required extensive repairs after many years in storage.

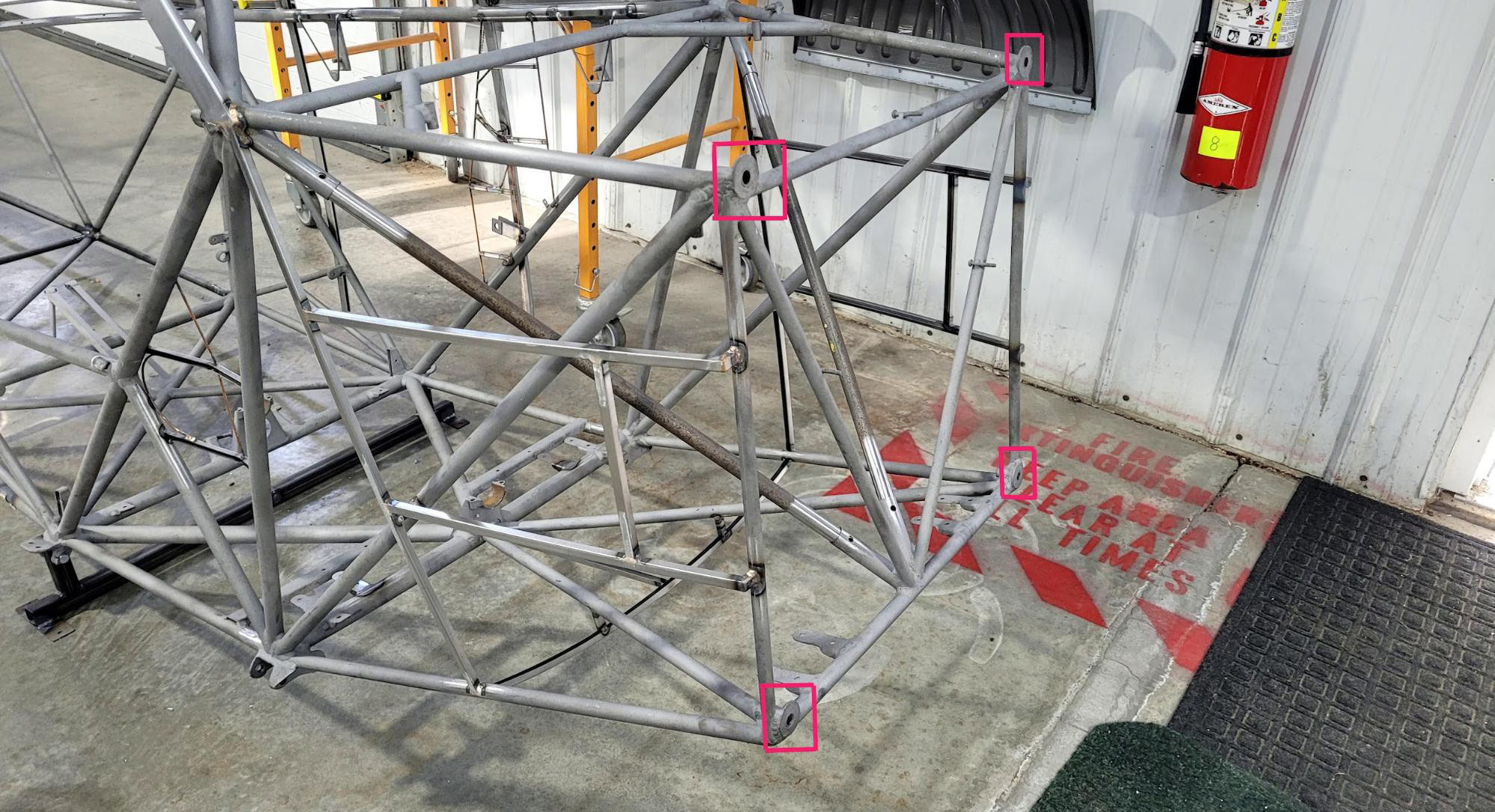

Fuselage Tube Frame

The fuselage frame suffered significant damage during an early-1950s crash while owned and operated by the Civil Air Patrol. AirCorps subcontracted out the fuselage frame repair.

Firewall Forward

Sheet metal components for the firewall-forward section were sourced from Univair, then carefully fitted and assembled. This assembly will be mounted to the fuselage frame once both are painted.

Many thanks to Chuck Cravens and AirCorps Aviation for providing this update on the L-4’s restoration progress. We look forwards to hearing more in the near future.

Richard Mallory Allnutt's aviation passion ignited at the 1974 Farnborough Airshow. Raised in 1970s Britain, he was immersed in WWII aviation lore. Moving to Washington DC, he frequented the Smithsonian’s National Air & Space Museum, meeting aviation legends.

After grad school, Richard worked for Lockheed-Martin but stayed devoted to aviation, volunteering at museums and honing his photography skills. In 2013, he became the founding editor of Warbirds News, now Vintage Aviation News. With around 800 articles written, he focuses on supporting grassroots aviation groups.

Richard values the connections made in the aviation community and is proud to help grow Vintage Aviation News.

Be the first to comment

Graphic Design, Branding and Aviation Art