Periodically, we have presented reports from Chuck Cravens detailing the restoration of an ultra-rare Beechcraft AT-10 Wichita WWII advanced, multi-engine trainer. As mentioned in previous articles, the project belongs to the Cadet Air Corps Museum and comprises the remains of several airframes, but is primarily focused upon Wichita 41-27322. The restoration is taking place at world-renowned AirCorps Aviation in Bemidji, Minnesota, and here is their latest update on progress with the Wichita as it stands presently:

Most of the recent work on the AT-10 has focused on the empennage. The restoration team removed, refurbished (or remade) and reinstalled each component from the original vertical stabilizer, one-at-a-time, so everything stayed in alignment, negating the need for a fixture. Some fuselage work also took place – such as test-fitting the tail wheel, tail cone, and the skin under the horizontal stabilizer. The team also applied a second coat of varnish to various wooden parts, along with the fuselage assembly and cockpit floor.

Empennage

As Aaron inspected the empennage, it became clear that the vast majority of its glued joints required separating and re-glueing. Thankfully, most of the interior wooden structure is in good shape, so Aaron, as already intimated, was able to use a procedure for restoring the vertical stabilizer without needing a fixture. He went through the structure, removing one rib at a time to assess its airworthiness potential, then refurbishing or remanufacturing it as necessary. He then added the now fully-airworthy component back to the main assembly before beginning the procedure anew for the next rib. By removing only one rib at a time, the overall structure maintained its alignment. Aaron only had to remake two of the ribs, being able to restore all of the other components by simply separating them into their individual parts and then re-gluing the joints.

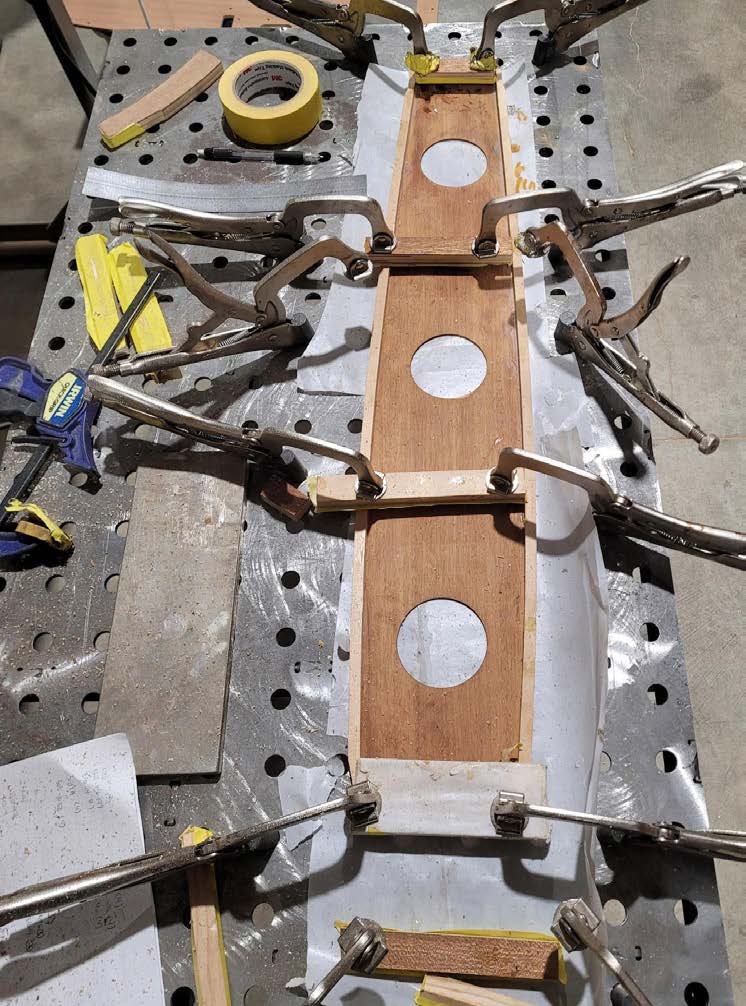

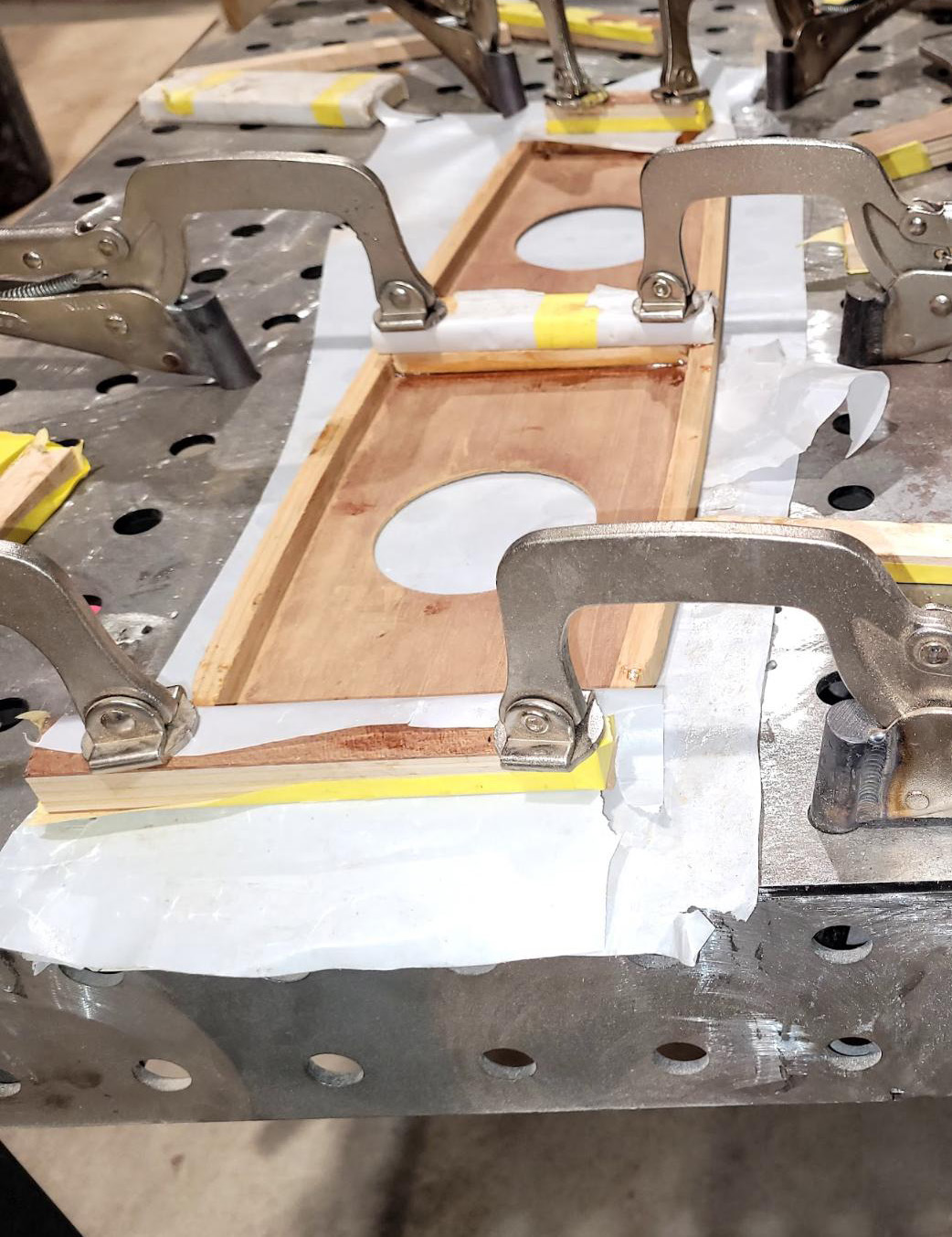

spar cap to create a perfect fit. (image via AirCorps Aviation)

leading edge. (image via AirCorps Aviation)

Fuselage

The cockpit section is currently at the paint shop where the dash and the instrument and auxiliary panels will receive a coat of black paint.

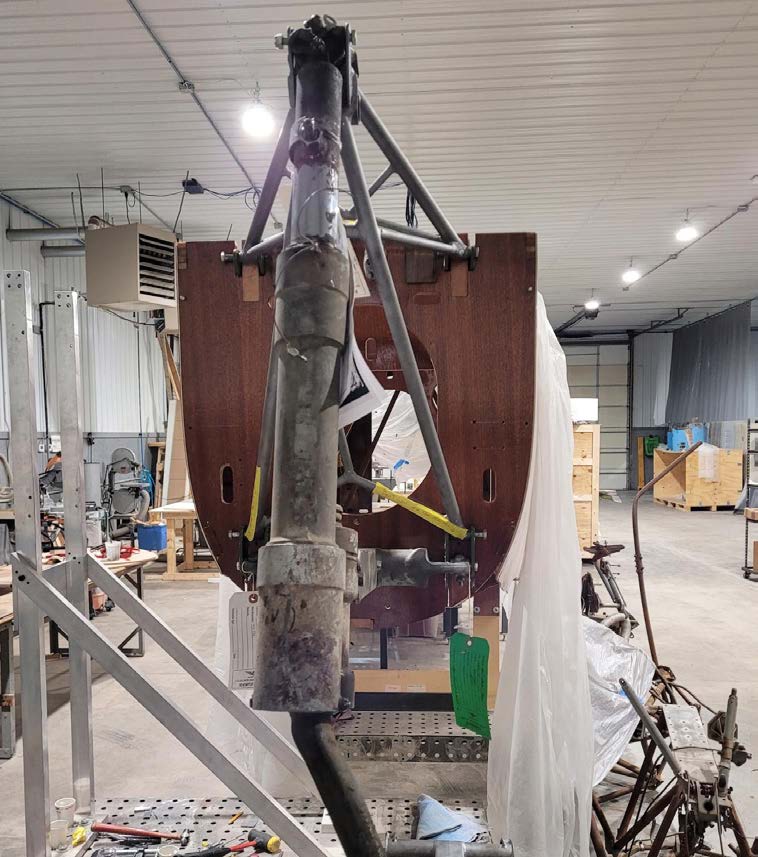

mounting structure. (image via AirCorps Aviation)

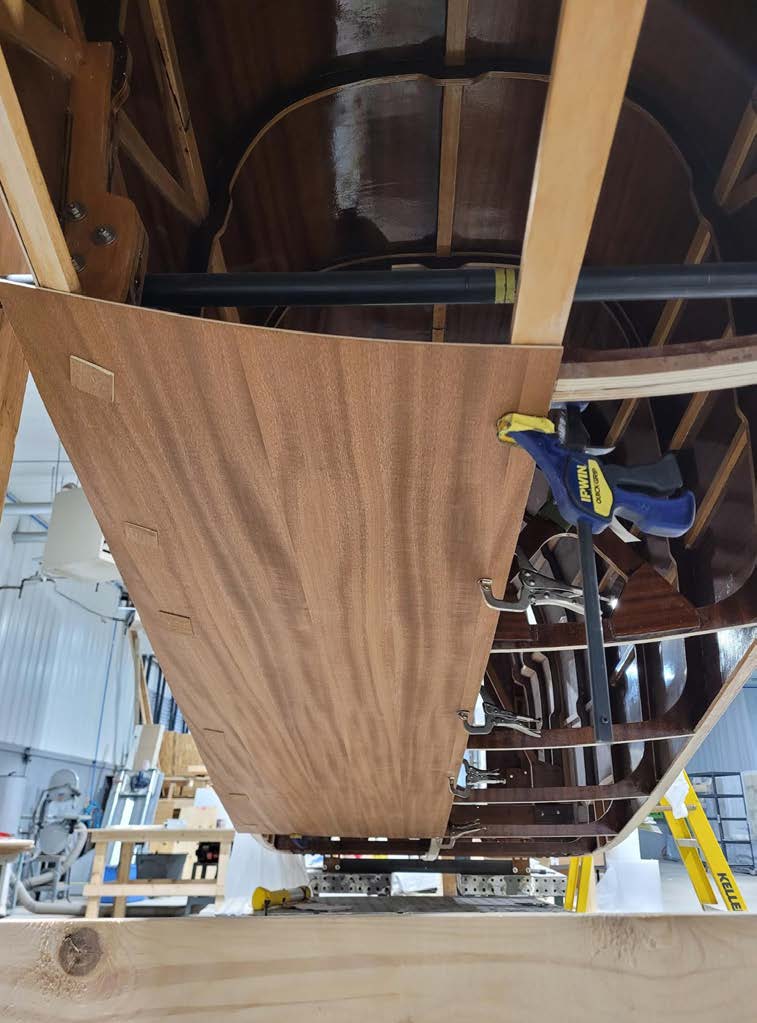

fuselage skin section. (image via AirCorps Aviation)

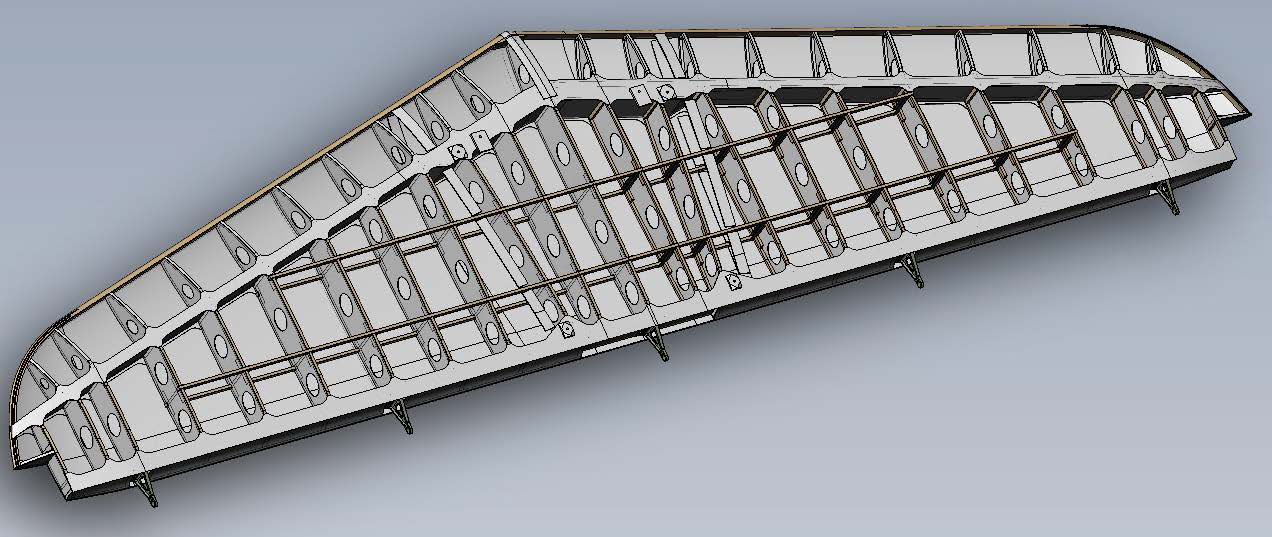

Nacelle Components

There are several landing gear mounts available to choose from; following inspection, the best two examples will become part of the restored AT-10.

Want to get involved?

AirCorps Aviation is constantly looking for new technical material related to the AT-10. Due to the rarity of this aircraft, and the relatively low number produced, acquiring engineering drawings, parts catalogs, maintenance manuals, and other documentation has been much more difficult than with our past restorations. If you have any AT-10 material or know someone who does, the team would love to hear from you!

Be a part of helping the AT-10 return to the skies! Contact Ester Aube, by email or phone [email protected] or 218-444-4478. Furthermore, should anyone wish to contribute to the Cadet Air Corps Museum’s efforts, please contact board members: Brooks Hurst: phone: +1-816-244-6927, e-mail: [email protected] Todd Graves: e-mail: [email protected]

Related Articles

Cadet Air Corps Museum AT-10 Restoration Report – Spring 2024

Cadet Air Corps Museum AT-10 Restoration Report

Cadet Air Corps Museum AT-10 Restoration – Fall 2023 Report

Cadet Air Corps Museum AT-10 Restoration – Spring 2021 Report

Cadet Air Corps Museum AT-10 Restoration – Summer 2020 Report

Cadet Air Corps Museum AT-10 Restoration – Fall 2018 Report

Richard Mallory Allnutt's aviation passion ignited at the 1974 Farnborough Airshow. Raised in 1970s Britain, he was immersed in WWII aviation lore. Moving to Washington DC, he frequented the Smithsonian’s National Air & Space Museum, meeting aviation legends.

After grad school, Richard worked for Lockheed-Martin but stayed devoted to aviation, volunteering at museums and honing his photography skills. In 2013, he became the founding editor of Warbirds News, now Vintage Aviation News. With around 800 articles written, he focuses on supporting grassroots aviation groups.

Richard values the connections made in the aviation community and is proud to help grow Vintage Aviation News.

Be the first to comment

Graphic Design, Branding and Aviation Art