Periodically, we have made restoration updates regarding the ultra-rare Burnelli CBY-3 Loadmaster at the New England Air Museum in Windsor Locks, Connecticut. However, it has been more than a year since our last progress report though, so we thought our readers would like to see how this remarkable and unique cargo aircraft is fairing today. The following details come from restoration Crew Chief, Harry Newman:

Work at the museum’s restoration facility resumed in May, in a limited fashion, as consistent with Connecticut’s official guidelines, which involve working in small groups, increased ventilation, the use of masks and social distancing.

Starboard Engine Cowlings

With the starboard engine accessory cowlings completed and installed, we were ready to begin the final painting of the aircraft’s right side, starting with the engine cowlings. This involved a number of sequential steps, including applying primer paint to the accessory cowls, fine sanding the resulting finish, masking the cowlings to extend the area of blue to match the port engine, applying the blue finish paint, and again masking the cowling for painting the remaining silver finish paint. As mentioned in earlier narratives, many hours of preparation are required for each hour of actual painting!

Fuselage Painting

While the fuselage top and underside had already received their silver finish coat, we still needed to paint the final layer on the sides. We therefore masked off the fuselage on the left side, finely sanded the primer coat, and then applied the silver finish coat. We then repeated this process on the right side. At long last, painting for the entire fuselage in its predominant colors of silver, blue and red was completed; a huge milestone in the restoration effort. The next steps will include applying the details and insignia to the fuselage. We will be working from a few rare color photographs to approximate the size and colors of these details.

Twin Boom Tail: Aerodynamic Detail

In the above photo and the close-up of the tail cone below, you can note the presence of aerodynamic features mounted where the vertical and horizontal stabilizers join. The aircraft was missing these details when the museum acquired her. However, a review of our photo archive reveals that the CBY-3 flew without them during her early years, but images from the late 1950s show them in place; probably to smooth the turbulent airflow which the 90 degree angles at these junctions created. As we begin to apply the final details to the completed fuselage, volunteer Tom Palshaw has taken on the task of replicating these features in fiberglass. Tom has made great progress towards this end, and is in the process of fitting his designs to the tail.

Cockpit

As detailed in earlier narratives, the cockpit restoration presented our volunteer crew with a number of challenges, including widespread corrosion, pre-existing damage and a great many missing parts and assemblies. The limited space in this area allowed only one or two people to work there at any given time, which prolonged the restoration effort significantly. While additional work remains, we have reached a significant, symbolic milestone with the installation of the main instrument panel in early June. Our next steps will involve the installation of cockpit windscreens, seats, the pilot controls pedestal, overhead panels and yoke wheels.

Propellers

With final assembly of the Burnelli’s propellers completed, we have now primed and painted them. The next steps will involve detail application, which will include painting the yellow blade tips and technical data, and affixing the Hamilton-Standard logo decals. The completed propeller assemblies will remain in storage for installation at a later date to allow final detailing on the aircraft.

Wings:

With completion of major fuselage painting operations, we will now begin final-painting the wings. In preparation, we have removed the right wing from its upright storage trolley and placed it flat on a movable cradle. We have prepared one side of the wing for final-painting in silver; when the paint cures, we will flip the wing over to repeat the process for the other side. We will then move on to the left wing, and repeat the same process. Early on in the CBY-3 restoration, we encountered great difficulty in removing the wings from the fuselage due to rust and corrosion in the wing mounts. we had to drill out several of the eight 1.0″ wing mounting pins, and none of them could be reused. Our machinists have therefore fabricated new mounting pins from stainless steel, and have prepared the fittings for wing-installation.

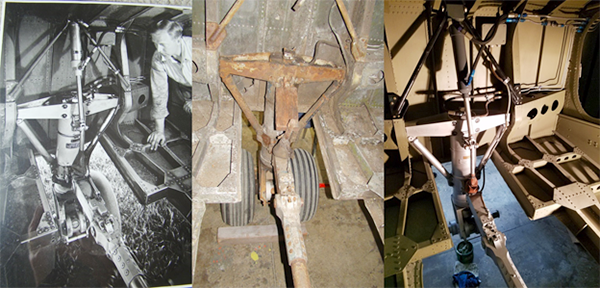

Landing Gear Wheel Wells

After many hours of work since the start of the restoration, the final details are underway in the landing gear wheel wells, with the fabrication and installation of the remaining hydraulic and fuel lines that run through these areas. Below is a composite photo comparison of the tail gear and wheel well showing the condition of the gear at three points in the CBY-3’s, 75-year history.

As a nonprofit 501(c)(3) organization the New England Air Museum depends on the generous support of individuals, companies and foundations to fulfill its mission. Click HERE to support the museum.

More photos of the restoration process.