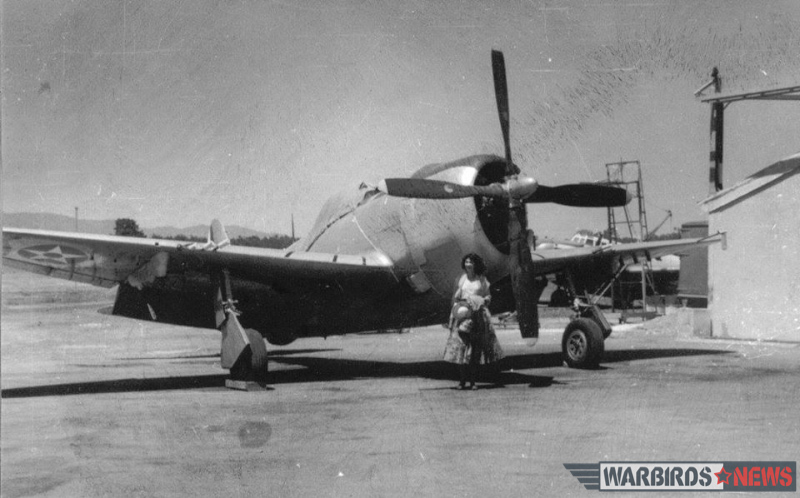

Last summer, we ran an article describing the arrival of the Commemorative Air Force’s partially rebuilt P-47N Thunderbolt (s/n 44-89136) at CAF Airbase Georgia. Since that date, the organization’s highly accomplished restoration team at Falcon Field in Peachtree City, Georgia has dug into the airframe. The following details describe some of what they have already accomplished in their quest to return the WWII fighter back to airworthy condition. While this particular P-47 arrived too late to see service overseas in WWII, it does have a fairly interesting post-war service history with the Guatemalan Air Force, which we shared in a great story in December, 2016.

In addition to the wing, smaller tasks were addressed, such as repairing damaged gun bays and ammunition areas. The team also managed to fix an old hangar damage from a few years ago, caused by a forklift that had damaged the forward fuselage. These repairs were quickly managed, adhering to the aircraft’s structural repair manual (SRM) guidelines, which remain relevant even though they were originally designed for combat readiness. The restoration also involved fitting critical parts for the landing gear and preparing to reattach the wings. Hawkins highlighted the importance of getting the landing gear operational—not only for functional reasons but also to make the aircraft more visually impressive to visitors. He admitted that a fully assembled aircraft would have a stronger “wow factor” for those unfamiliar with aviation, which was an ongoing motivation for the team.

In addition to the wing, smaller tasks were addressed, such as repairing damaged gun bays and ammunition areas. The team also managed to fix an old hangar damage from a few years ago, caused by a forklift that had damaged the forward fuselage. These repairs were quickly managed, adhering to the aircraft’s structural repair manual (SRM) guidelines, which remain relevant even though they were originally designed for combat readiness. The restoration also involved fitting critical parts for the landing gear and preparing to reattach the wings. Hawkins highlighted the importance of getting the landing gear operational—not only for functional reasons but also to make the aircraft more visually impressive to visitors. He admitted that a fully assembled aircraft would have a stronger “wow factor” for those unfamiliar with aviation, which was an ongoing motivation for the team.

As the restoration progressed, the team worked closely with Air Corps, especially when it came to intricate metalwork and fabricating rare parts like latching systems for the gun and ammo bay doors. Despite some delays, due in part to Air Corps’ involvement in other projects, the partnership remained productive, and parts were gradually obtained and installed. Hawkins also explained the careful sequence required in assembling certain parts. For example, wing components needed to be installed in a specific order, with some items, such as flight controls, being held off until later stages of the restoration. A notable moment in the project involved transporting parts, including the cowling and flaps, to Air Corps for further work. The collaboration between CAF Airbase Georgia and Air Corps has been essential in the restoration, and they continue to work on a priority list that will ensure the aircraft is restored to its former glory.

As the restoration progressed, the team worked closely with Air Corps, especially when it came to intricate metalwork and fabricating rare parts like latching systems for the gun and ammo bay doors. Despite some delays, due in part to Air Corps’ involvement in other projects, the partnership remained productive, and parts were gradually obtained and installed. Hawkins also explained the careful sequence required in assembling certain parts. For example, wing components needed to be installed in a specific order, with some items, such as flight controls, being held off until later stages of the restoration. A notable moment in the project involved transporting parts, including the cowling and flaps, to Air Corps for further work. The collaboration between CAF Airbase Georgia and Air Corps has been essential in the restoration, and they continue to work on a priority list that will ensure the aircraft is restored to its former glory.

Hawkins praised the efforts of his team, noting that some members, such as Dennis Beach, had been putting in countless hours to move the project forward. Even while some were away on much-needed vacations, the work continued. For example, Steve Schenkel had been working on the tail wheel, discovering and addressing issues like missing metering pins, essential for the aircraft’s shock absorption system. In addition to the mechanical work, efforts were underway to rebuild the aircraft’s wiring systems. Hawkins highlighted that while wiring can seem daunting, it’s a manageable task, and the team has been making steady progress, with some members even constructing custom harness boards to assist in the process.

Hawkins praised the efforts of his team, noting that some members, such as Dennis Beach, had been putting in countless hours to move the project forward. Even while some were away on much-needed vacations, the work continued. For example, Steve Schenkel had been working on the tail wheel, discovering and addressing issues like missing metering pins, essential for the aircraft’s shock absorption system. In addition to the mechanical work, efforts were underway to rebuild the aircraft’s wiring systems. Hawkins highlighted that while wiring can seem daunting, it’s a manageable task, and the team has been making steady progress, with some members even constructing custom harness boards to assist in the process.

When this P-47N Thunderbolt is finished being rebuilt to flyable status, will it be restored without markings, in an overall coat of silver paint with a black, anti-glare panel in front of the cockpit as it saw actual combat service in Guatemala? Or will it be painted in fictitious USAAF or possibly in post WWII USAF markings? Please reply.