WarbirdsNews has received the latest update from Tom Reilly on the XP-82 Twin Mustang under restoration in his workshop in Douglas, Georgia. We thought you’d like to see what they’ve been up to! Click the jump to find out more…

Wings

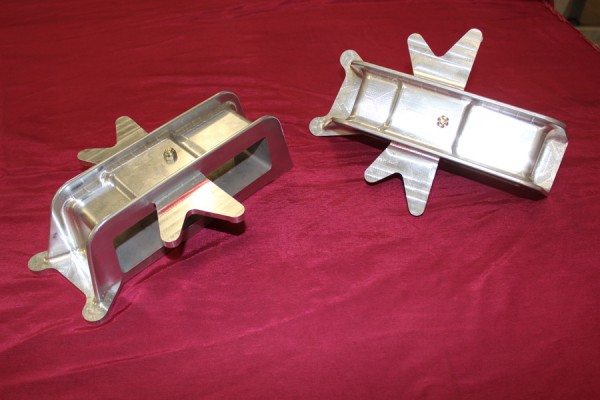

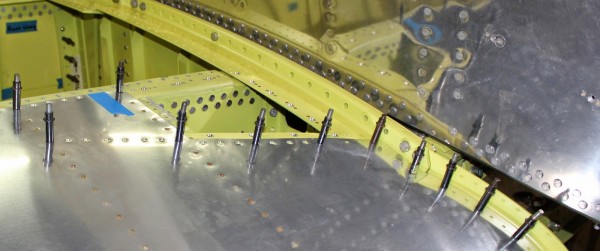

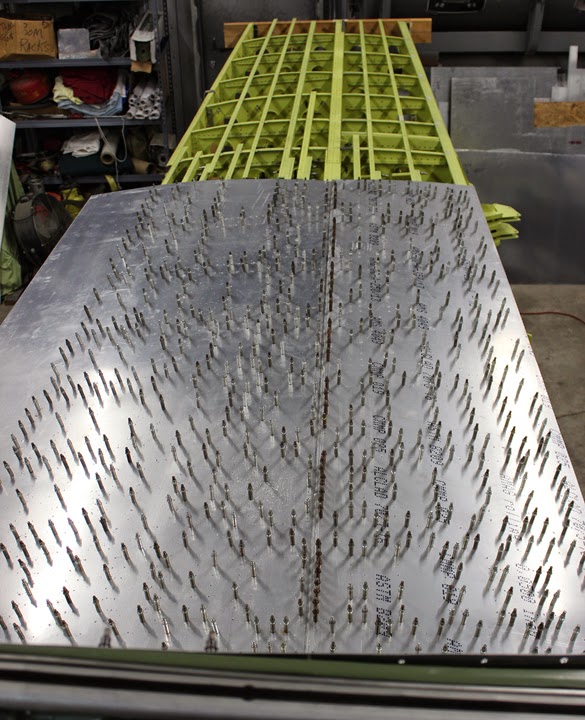

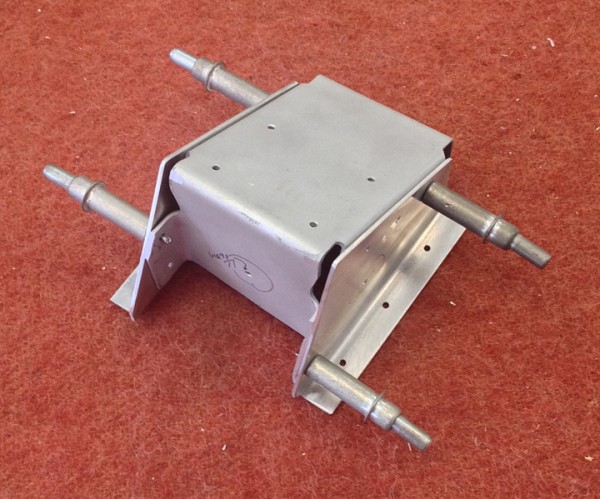

The right-hand wing leading edge skin is now completely riveted in place as are all of the internal close-out doubler plates in the left and right-hand wing forward spars. One of the team’s machine shops has completed the two aileron sector support boxes, and they are now fitted into the leading edge spars at the root end. The flat skins for the right-hand wing are part way through the drilling and dimpling process. Final riveting for the skins will take place once the wing is installed in its jig.

One structural access panel installation on the top inboard leading edge of each wing had the team scratching their heads for a while. The factory drawings showed these access panels (XP all the way through the G models) right above the sector support boxes so one could gain access to the sector for adjustment. Without these access panels installed, one would have to remove the wing for final interior cable adjustments. However, countless pictures of other F-82s show no evidence of having the access panels installed. But the original XP-82 top wing skins showed clear evidence of the panel installation, so Tom made the decision to install them to preserve the airframe’s authenticity.

Another machine shop is hard at work manufacturing the aileron hinge points and non-boosted actuators. The sub-assembly work on the left-hand wing structure has now caught up with the right-hand wing, and the team has started preliminary leading edge and surface skin drilling with reduced-size drill bits.

Fuselages

With the canopy jettison systems complete, the team has now finished the sheet metal panels that cover the outside of the canopy rails. They all had stepped joggles rolled into them to accept the lower edges of the canopy frames. The restoration crew needed specially shaped beading rollers to press in these joggles.

The team is currently assembling both windshield frames and their new bows. The have already finished installing the glass into one of the two canopy frames. The second canopy frame requires the installation of a little more internal skin structure and the new canopy bow before it can receive its glass.

The left-hand pair of rudder pedals are fully assembled and installed, along with their balance cables.

The throttle and prop quadrant cables that synchronize the left and right quadrants together are beginning to take shape as well.

Center Section

The newly completed control rods (welded and painted) that operate the forward spar uplock hook for the forward edge of the main landing gear door are installed.

One of Tom’s men completed the aileron trim gear box mounted on the left aft spar. It’s a very complex little structure with all kinds of bends and angles designed in it.

And that’s all for this month. Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in early May for the next installation following the XP-82’s road to recovery!

Please click HERE for some of our previous updates.

Richard Mallory Allnutt's aviation passion ignited at the 1974 Farnborough Airshow. Raised in 1970s Britain, he was immersed in WWII aviation lore. Moving to Washington DC, he frequented the Smithsonian’s National Air & Space Museum, meeting aviation legends.

After grad school, Richard worked for Lockheed-Martin but stayed devoted to aviation, volunteering at museums and honing his photography skills. In 2013, he became the founding editor of Warbirds News, now Vintage Aviation News. With around 800 articles written, he focuses on supporting grassroots aviation groups.

Richard values the connections made in the aviation community and is proud to help grow Vintage Aviation News.

Miracle workers! Can’t wait to see it done! Wish I had the training to do this kind of work.

Nice, very nice.

I can’t wait to see the end result of your efforts to bringing this aircraft back to life. I am sure that all aviation fans of the P-51 Mustang are proud of the work that you are doing. Keep up the good work folks!

very cool to see this plane coming along so far.

What a great project! It will be just wonderful to hear those twin Merlins singing and to see that unmistakable profile in the sky again.

It would be nice if the restoration deviates from the authentic by installing Merlin engines, rather than the original Allisons.

Saaaaweet!

Beautiful! I’m quite envious. I enjoyed every moment helping to restore & maintain Warbirds:

FG-1D “VF17 #17”

FG-1D “VF17 #29”

P-51D “Shangri-la”

P-51D “Hurry Home Honey”

Hope y’all get maximum satisfaction. Keep yer sanity. You are truly craftsmen.

Awesome job, congratulations