by Moreno Aguiari

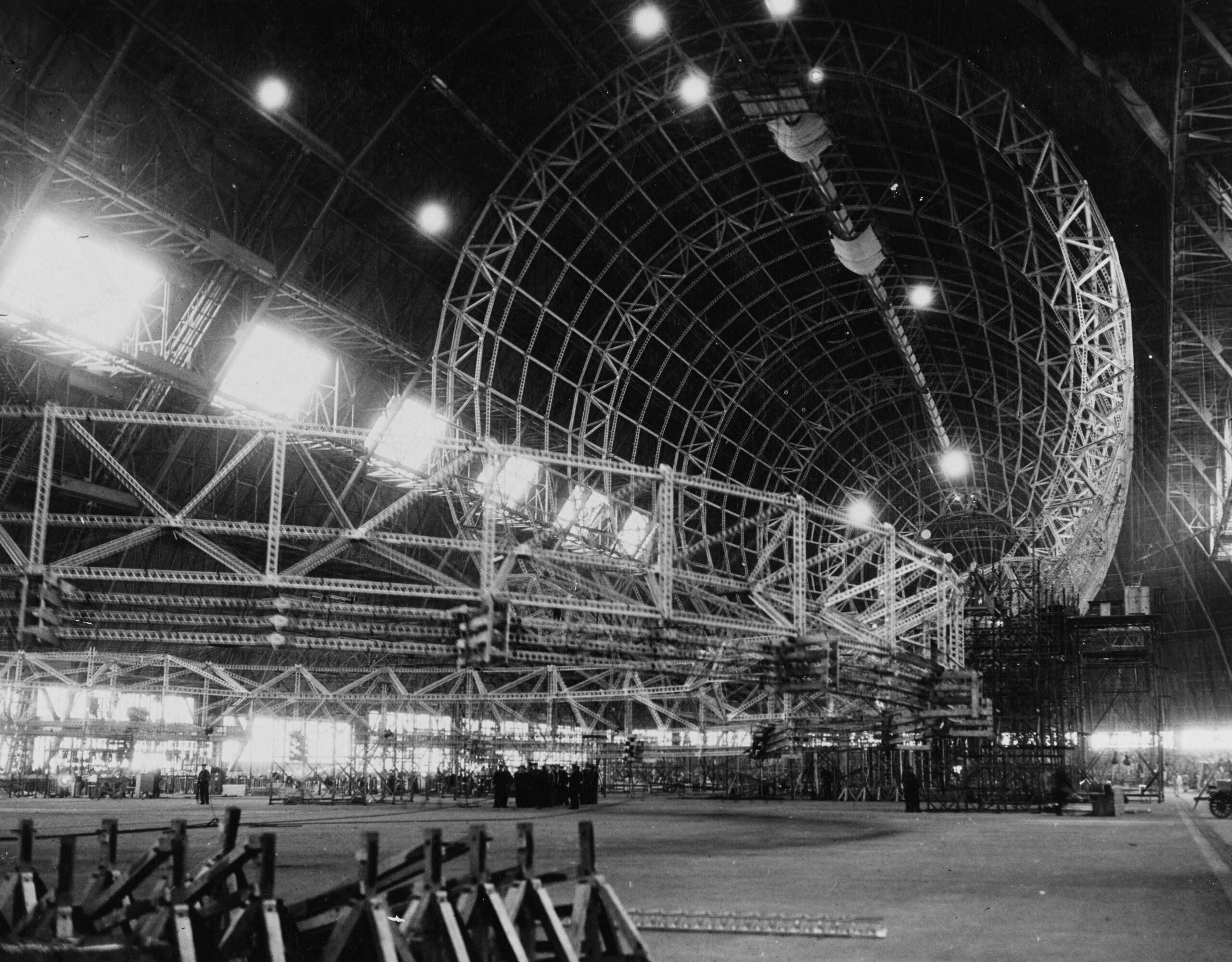

I have a passion for aviation history, much like most of you reading this article I suspect. When traveling, I do my best to search for any locations nearby my intended destination which might hold a place in aviation lore; luckily, the United States still offers plenty of such sites. During a recent trip to Akron, Ohio, I took the opportunity to visit the former Goodyear Aircraft Corporation (GAC) factory located within the premises of Akron-Fulton Airport. This was the birthplace of America’s brief flirtation with dirigibles, built and launched from the gargantuan Airdock, which is still standing and a protected structure.

The industrial buildings surrounding the Airdock also housed a substantive manufacturing facility, which produced many subassemblies for American aircraft during WWII… but perhaps more importantly, it was also here where GAC produced under license more than four thousand examples of Chance-Vought’s legendary F4U Corsair, arguably the most effective American naval fighter of WWII. While Goodyear eventually sold the site on, most of the factory buildings still survive, occupied by a plethora of present-day companies ranging from Waste Management to LTA Research, an organization which is designing the next generation of airships, rather appropriately, within the Airdock.

Before we get to my video walk-around of the former Goodyear Aircraft factory in Akron, it might be worth providing a brief recap of the company’s history in aviation. As with most American businesses soon after the onset of World War II, Goodyear shifted its focus in support of the war effort. The site in Akron, Ohio featured two Goodyear entities: the Goodyear Tire and Rubber Company and the Goodyear Aircraft Corporation. Goodyear Tire and Rubber, as the name suggests, produced numerous products involving the use of rubber. These ranged from aircraft wheels, brakes, barrage balloons, half-track tracks, combat tire rims, road wheels, gun carriage tracks, synthetic rubber softeners, self sealing fuel tanks, rubberized fabrics, plastic containers, reclaimed rubber, tires and tubes, bullet seal hose, hydraulic brake hose, aircraft fuel oil and coolant hose, gas masks, agricultural V-belts, steel cable V-belts, earthmover tires, large rubber landing craft, electric power transmission, plus many other related items.

While there was an obvious need for Goodyear to continue their core business manufacturing tires and other vital rubber products, they also began making components for fixed-wing airplanes. This began in earnest during 1939 when the newly-renamed Goodyear Aircraft Company received a contract from the Glenn L. Martin Company to build empennages for a then brand new medium bomber design, the Martin B-26 Marauder.

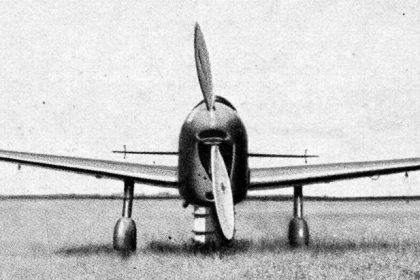

Goodyear, with abundant available manufacturing space and the requisite skills in its workforce, was an ideal choice for this task. Their success in fulfilling this contract led the company to receive orders for numerous other aviation-related subassemblies such as outer wings for the B-26 Marauder, B-29 fuselage and empennage assemblies, P-61 outer wings and empennage assemblies, aircraft wheels and brakes, assemblies for the TBF Avenger, not to mention control surfaces for the P-38 Lightning and F6F Hellcat. As already noted, perhaps their most important and well-known task involved the production of Corsairs. At its peak, there were some 35,000 factory workers involved in this effort. During the last three years of World War II Goodyear Aircraft constructed more than 4,000 Corsairs in three distinct variants, the FG-1, FG-1A and FG-1D (roughly equivalent to Chance Vought’s F4U-1, F4U-1A and F4U-1D). Had the war continued, the company would also have built F4U-4s under license as the FG-4. Of additional note, Goodyear’s reputation was such that they received a contract to develop Vought’s so-called Super Corsair, a variant of the F4U-1 modified to accept the massive R-4360 powerplant. GAC produced several prototypes as the XF2G-1 and XF2G-2 and a handful of pre-production examples before the war ended; that event, of course, precipitated contract cancellation. The images below show aircraft production scenes at the GAC plant in Akron, Ohio during WWII, all but one of which involves Corsair manufacture.

With their part in Corsair production concluded, Goodyear handed over its Akron plant to the U.S. Navy in January 1948; it became the basis for Naval Air Station Akron. For a look at the old factory buildings as they stand now… please see my new video below.

Many thanks to Jim Harley for the use of his “Then and Now” images. For those who don’t know, Jim’s father worked on Corsair production at Goodyear Aircraft during WWII, so has a special place in his heart for the old factory in Akron. Jim Harley also flew regularly for the Collings Foundation.

Thank you for posting this information! My grandmother worked there building Corsairs during the war. She is 103 now.

Your Grandmother was from an era in America righty called the “Greatest Generation”. They endured without compliant, deprivations that seemingly Americans are incapable of withstanding now. God Bless and keep her memory.

My Grandmother worked inside the Air dock during WW11, helping to build those Airplanes

Thank you for posting the photos and information. Both of my grandparents worked at this factory: my grandmother was a “Rosie the Riveter” and my grandfather was a plant manager. I wish I asked more questions before they passed away.