Warbird Digest has just received the November, 2020 report from Chuck Cravens concerning the restoration of the Dakota Territory Air Museum’s P-47D Thunderbolt 42-27609 at AirCorps Aviation in Bemidji, Minnesota. We thought our readers would be very interested to see how the project has progressed since our last article on this important project. So without further ado, here it goes!

Update

Some exciting news came from subcontractors this month; John Castorina has completed bench-testing the SCR 274 radio set up for the P-47, and I am excited to incorporate his written description of his fine work into this update. Another exciting development is that Anderson Aeromotive has the Thunderbolt’s R-2800 power plant ready to test run. Here at the AirCorps Aviation shop, the wing work and some fuselage details continue to progress.

Wings

Fuselage

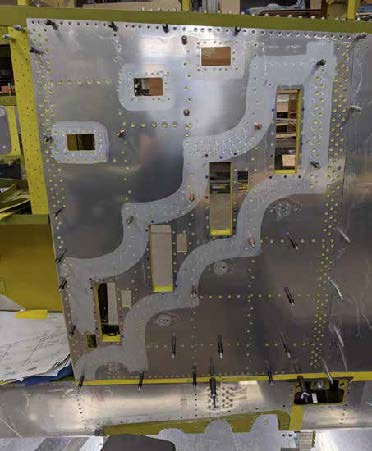

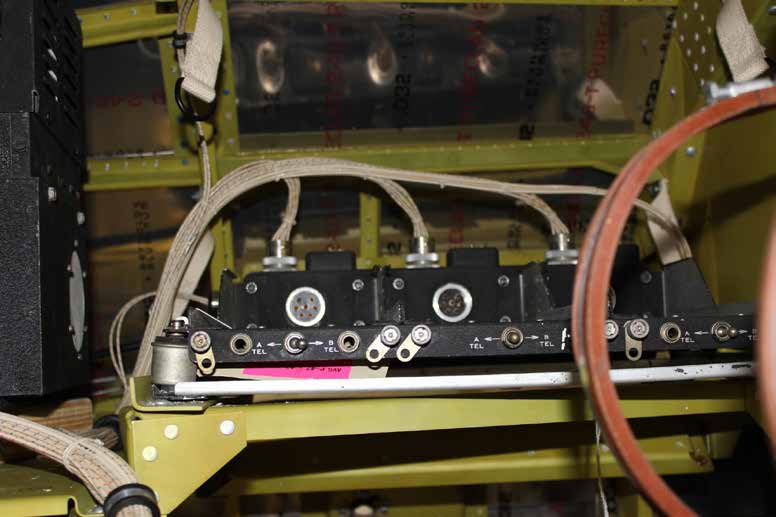

Preparations to install the radio system, some systems detail work, and firewall forward structural work were the areas of progress this month.

Radio Restoration

by John Castorina

John Castorina consented to write about his work on the communications radios for 42-27609. His writing is exactly what was needed to explain the radio system work, so he is our contributing author this month.

First a little background:

John worked for Communications Satellite Corporation for over 20 years and is a commercial pilot. He is a Cessna 180 owner and 2015 Oshkosh winner. For AirCorps Aviation, John restored the radio sets for Sierra Sue II (Reserve Grand Champion 2015) and Lopes Hope III (Grand Champion 2018). Currently, John is the Director of Maintenance at the Palm Springs Air Museum and flies North American B-25J Executive Sweet and Douglas C-47B What’s Up Doc? whenever possible. He is the proprietor of Warbird Radios, located on Santa Paula Airport, Santa Paula, California.

Restoration of the communications radios for the Dakota Territory Air Museum’s P-47D-23RA Thunderbolt has progressed to the integrated testing phase.

Here’s a little background on these radios, and a short description of the restoration process.

Designated “SCR-274N” and commonly referred to as “Command Sets”, the SCR-274N was adopted by the Signal Corps as the main aircraft communications radio set for WW2. The SCR-274N is similar to the Navy ARA and ATA sets, whereas the ARC-5 sets came along later and have significant differences from the earlier sets, despite similar appearance. The SCR-274N was found in all aircraft types, from single-seat fighters to large multi-engine bombers. The modular design allowed for any given installation to consist of from 1 to 4 transmitters and 1 to 3 receivers.

All installations require one modulator, which also supplies power to the transmitters, appropriate control boxes and mountings. Operating in the High Frequency (HF) range, four different receivers and four different transmitters cover the frequency range 0.19 MHz to 9.1 MHz. The transmitter power output ranges from about 40 to 60 watts, depending on mode (AM voice, cw, or amplitude-modulated cw).

The transmitters were tuned by the ground crew to their assigned frequencies before a mission, and could not be changed while airborne. In contrast, the receivers were tuned by the radio operator or pilot while airborne using a remote box mechanically coupled to the receivers with flexible drive cables, similar to speedometer cables.

For the Dakota Territory Air Museum’s P-47D-23RA, three receivers and two transmitters are required. As always, the first step in the restoration process was to locate all the components in un-modified condition and with the best cosmetic appearance. Even though it’s been 75+ years since these components were manufactured, many are still available but the majority have been modified by amateur radio operators for use on the “ham” bands and operation from “house” power, versus 28 volt DC aircraft systems.

Of those that survived un-modified, many have suffered the ravages of poor storage – dents, corrosion, varmints and other conditions – that render them difficult, in some cases impossible, to restore to “as-built” condition. Cosmetic restoration of each unit occurs first, after disassembly, and involves careful removal of all dirt, stains, dents and other imperfections. I take pictures of each unit so that, if required, all factory markings can be re-applied exactly as found after a unit is deep cleaned or re-painted. All electrical contacts in relays and connectors are cleaned and treated with a special product which inhibits corrosion and promotes conductivity. Finally, all tubes are dynamically tested to ensure they meet factory test criteria.

The second most time-consuming task (after cosmetic restoration) is the removal and replacement of every capacitor in each transmitter and receiver. Capacitors are the first items to die electrically, and most have long ago reached this stage. To maintain the original appearance, the capacitor cases are gutted, then new modern components are installed in the original case, followed by cosmetic work to ensure the final appearance is close to what it was when the units were built. Dynamotors are opened, cleaned, and old (usually hardened) grease is removed from the bearings. New grease is packed in, and brushes are checked and replaced if necessary.

If needed, the exteriors are stripped and repainted in black wrinkle, then inspection markings are re-applied using custom rubber stamps which duplicate the factory markings. The same basic electrical and cosmetic restoration process is performed on each of the accessories – transmitter control box, receiver remote tuning box, antenna relay, and each of the mounting bases. Once complete, the units are partially re-assembled and then integrated testing of the SCR-274N set can begin.

The initial test consists simply of applying power to each unit, listening for defects in the dynamotors and observing that none of the magic black smoke gets out of any part of the radio set. Now a functional test – headsets and signal generators are connected to the receivers, power meters are connected to the transmitters, then a check is made of each unit that basic functions are working. Units which fail this check are isolated and repaired as required before continuing with the test procedures. It is worth mentioning that out of at least 20 transmitters and receivers I’ve restored, I can think of only a couple of units that did not work the first time at this point – pretty good considering the age!

Using modern digital test equipment, each unit is then tuned for performance to be equal to or better than the factory specifications. This involves precise measurement of receiver sensitivity, dial calibration, transmitter power output across the tuning range at multiple frequencies, audio output and distortion. All units are then fully re-assembled with their covers and all screws (seems like hundreds of them) and then a final test is performed prior to packing them for shipment back to AirCorps Aviation.

When the Dakota Territory Air Museum’s P-47 is complete, licensed amateur radio operators will be able to demonstrate the capability of the SCR-274N using AM (amplitude modulation) voice communications on the 40 and 80 meter ham bands! (7175 and 3985 kHz respectively).

Special thanks to John Castorina for taking the time to write this excellent report on the radio system restoration.

Power Plant

The Pratt & Whitney R-2800 was the engine used in P-47s and many other WWII fighters, bombers, and transports.

The R-2800 is an eighteen cylinder, double-row, air cooled radial engine. The cylinder bore is 5.75 inches and the stroke is 6.0 inches, resulting in a total displacement of 2,804 cubic inches.

To give a rough analogy of the sheer size of the cylinders, consider that one cylinder of an R-2800 displaces slightly more than the entire standard four cylinder engine in a Ford Fusion or Toyota Camry.

The R-2800-59 is the engine variant used in the P-47D-23RA. The Dash 59 had General Electric magnetos, a single-stage, single-speed supercharger integral to the engine, with additional boost provided through the complex ducting of the General Electric C-23 turbo supercharger system, and water injection. It was rated at 2,300 hp when in war emergency power setting with ADI (anti detonation water injection). [Graham White, R-2800, Pratt & Whitney’s Dependable Masterpiece. Warrendale, PA, Society of Automotive Engineers, Inc., 2001),375-414]

Some have called the Pratt & Whitney R-2800 Double Wasp engine the most significant aircraft engine built in the United States during WWII [Graham White, R-2800, Pratt & Whitney’s Dependable Masterpiece. Warrendale, PA, Society of Automotive Engineers, Inc., 1995),222-253]. Like so many statements of this type, it is certainly debatable; however, there is a great case supporting this superlative.

It wasn’t the most powerful engine, didn’t have the best power-to-weight ratio, and wasn’t the most technologically advanced, however, the R-2800 was near the top in all of those characteristics. The big radial was legendary for taking incredible damage and continuing to run. It was exceptionally reliable, cheaper and easier to maintain than an Allison or Merlin, and had relatively low specific fuel consumption for its size and power.

Despite not being the absolute best in any one category, this combination of qualities produced an engine so useful that it powered many WWII combat aircraft and after the war both the military and commercial airliners used it for quite some time.

A few of the best known R-2800 powered aircraft were:

- Republic P-47 Thunderbolt

- Vought F4U Corsair

- Grumman F6F Hellcat

- Curtiss C-46 Commando

- Douglas A-26 Invader

- Lockheed Ventura/B-34 Lexington/PV-1

- Ventura/PV-2 Harpoon

- Martin B-26 Marauder

- Martin PBM-5 Mariner

- Northrop P-61 Black Widow

- Grumman F7F Tigercat

- Grumman F8F Bearcat

- Fairchild C-82 Packet

- Fairchild C-123 Provider

- North American AJ Savage

Post war civilian applications included the:

- Canadair CL-215

- Canadair C-5 North Star

- Convair 240, 340, and 440

- Martin 2-0-2

- Martin 4-0-4

- Douglas DC-6

And that’s all for this month. We wish to thank AirCorps Aviation, Chuck Cravens for making this report possible! We look forwards to bringing more restoration reports on progress with this rare machine in the coming months. Be safe, and be well