Since our previous update last fall, the Hawker Typhoon Preservation Group has continued their hard work in both raising funds and coordinating the progress on the restoration of Hawker Typhoon Mk.Ib RB396. The rear fuselage monocoque is coming together quite quickly now at Airframe Assemblies on the Isle of Wight, and if fundraising is sufficient to cover the expenses, the team expects to have this finished sometime this summer. The following describes what they have undertaken up til now…

December 2020 was just as busy for Airframe Assemblies as any other recent month and the progress on RB396’s rear fuselage showed no signs of slowing down. Indeed, there has been a five-fold increase in the monthly spend, and therefore progress, as a result of the refocus and restructuring events of the last year.

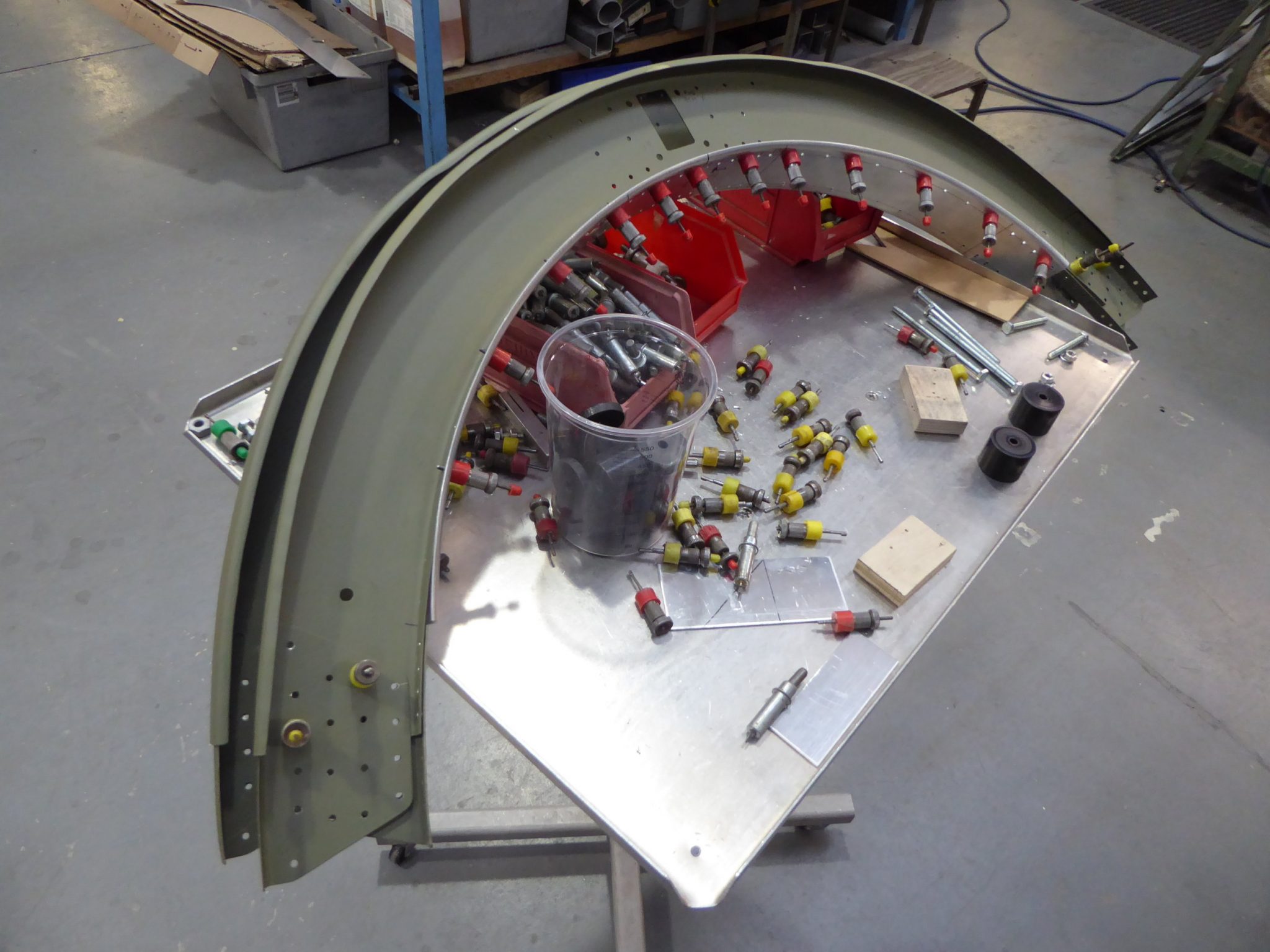

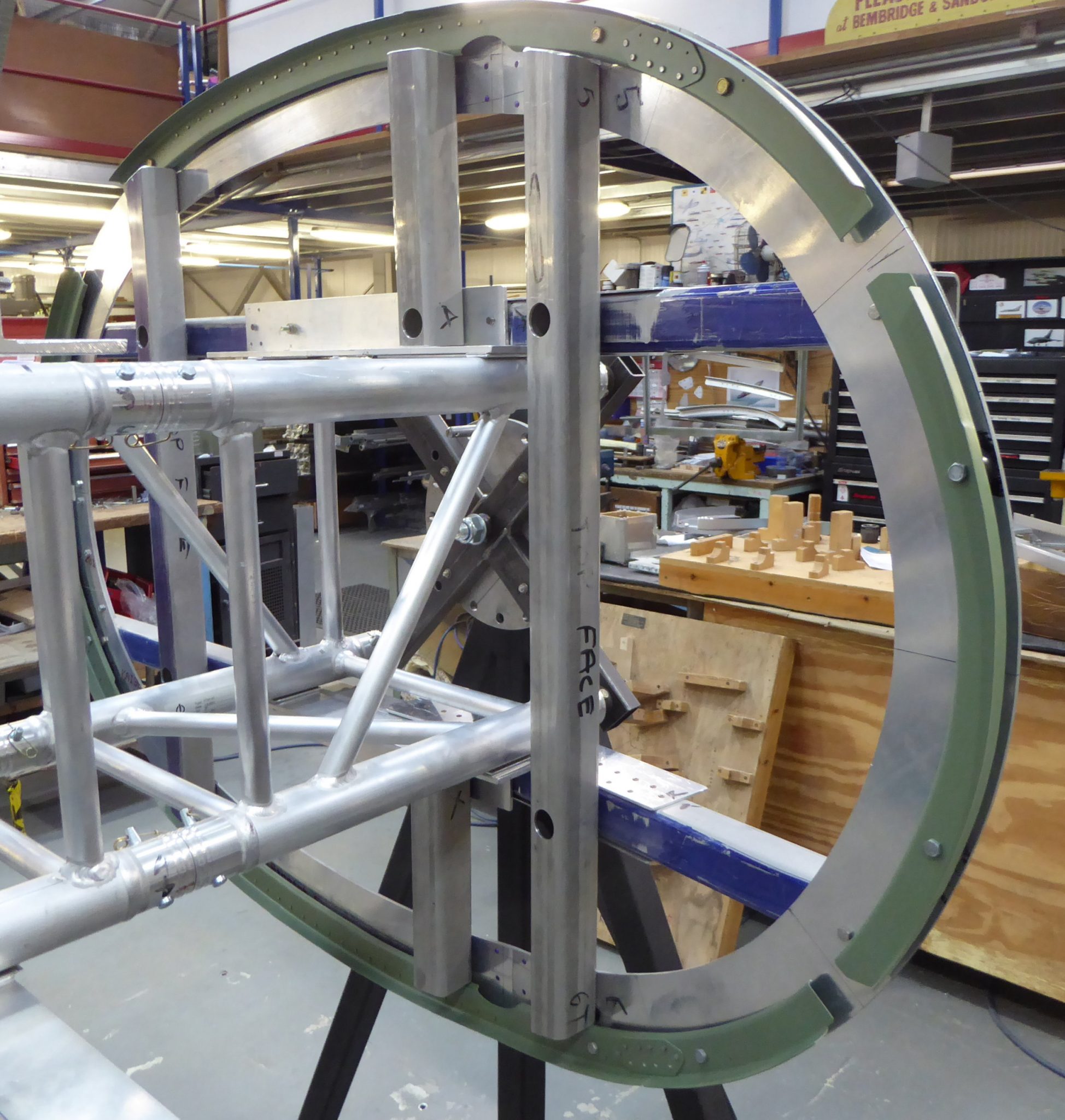

With the rear fuselage Frames B to J/K complete, the main area of activity for December was the rebuild of Frame A and its associated fittings. Frame A is the most complex and critical frame within the rear monocoque, being the juncture with the forward fuselage section. The various sheet metal segments that make up the frame have been refurbished or remade as required.

The four frame segments are drilled to take the machined fittings that pick up the tubular joining structure. Each of these four joints is rather complex, and no drawings exist (that the project has access to) showing the method of fixing these into position, so the team at Airframe Assemblies have to interpolate information from other drawings and other parts showing patterns of the area.

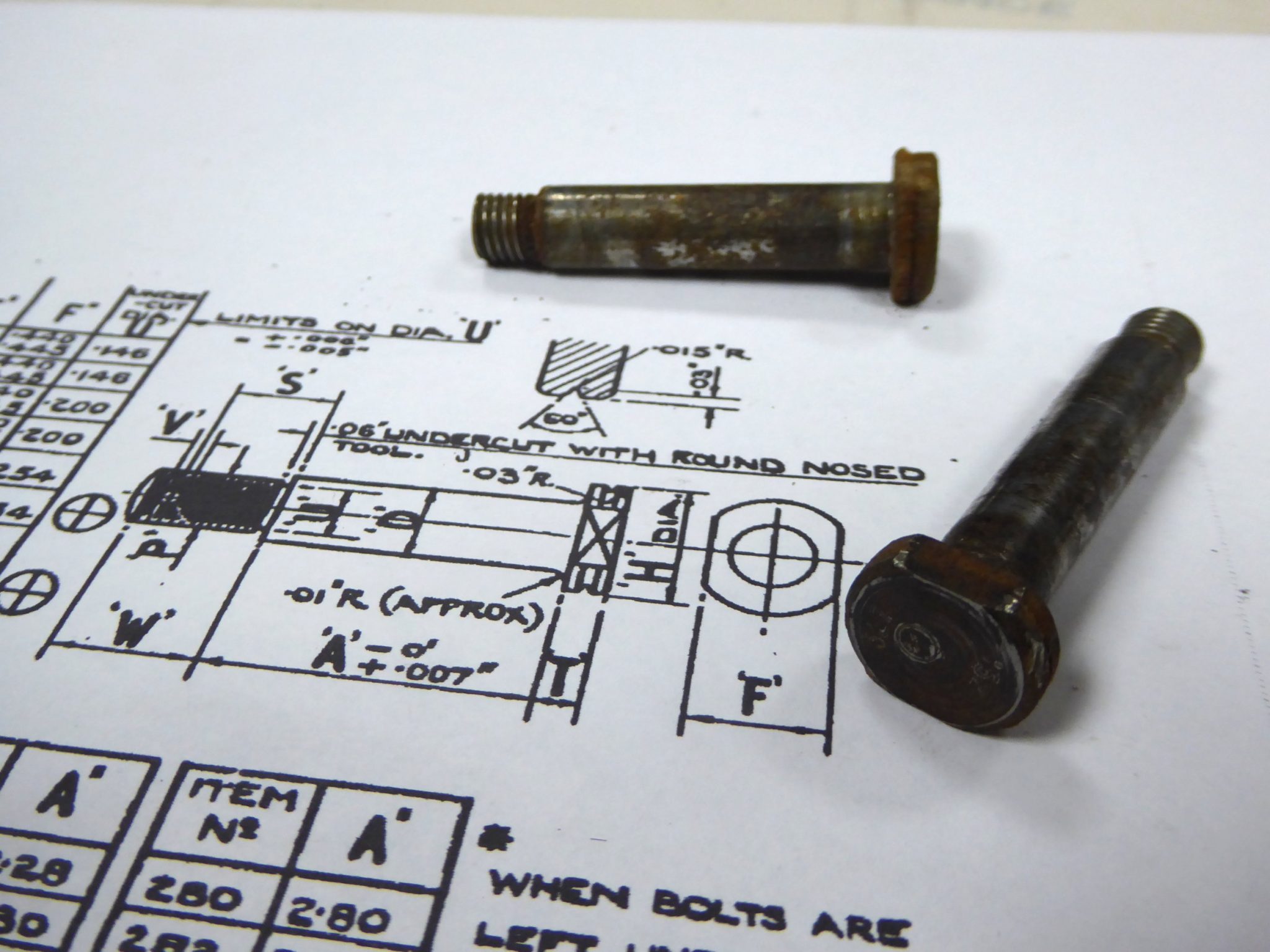

The company made a careful study of the original fasteners removed from RB396. They found that while some were standard A15 aircraft spec steel bolts, which are still available, others were special (A.std). Hawker had made these latter bolts to their own particular specifications to fit certain holes with close-tolerance shear bushes. Luckily these A.std sheet drawings do exist, so the team will be able to remanufacture a set to the original design.

Significant other work has included the manufacture and fitting of the boundary members which form the very forward edge of the monocoque. These, like all other parts, are very complex and take considerable expertise to create, along with many hours of skilled labour.

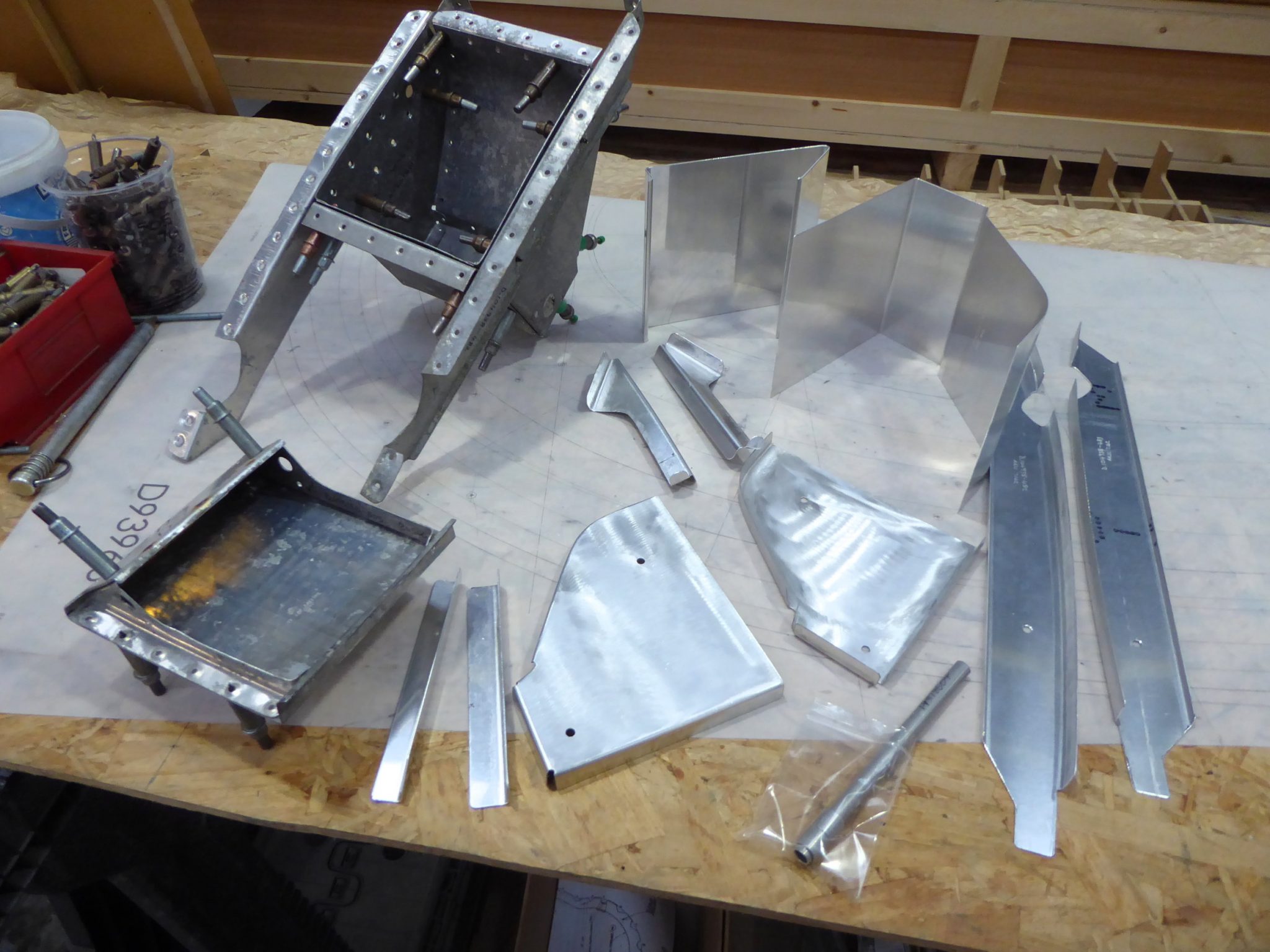

The team has also created a sheet metal detail kit for the upper footstep assembly. This was missing from RB396’s original rear fuselage section, so Airframe Assemblies had to reverse engineer the design, as no drawings for this section are known presently to exist. They were able to obtain pattern-parts by carefully removing an equivalent assembly from a Tempest II fuselage, having concluded that the two aircraft types used the same design.

The five-fold increase in the monthly spend and the considerable progress as a result are due to the generosity of those who have supported the project to date, especially those who have joined the Platinum Club since its launch on the 1st April 2020. The project is not fully funded and the team are continually working hard to raise funds to keep the rebuild on track. To support them, and play your part in this unique, once in a lifetime project, please get involved. Only with your support can the rebuild progress and RB396 continue her journey back to the skies once more.

Many thanks to the Hawker Typhoon Preservation Group for this latest update. We’ve been told that once they have secured funding to restore the rear fuselage monocoque, the forward fuselage/cockpit section will be shipped off for restoration too. Exciting times! Please do click HERE to learn how you can contribute to this marvelous project, which will eventually see the all-but-extinct Hawker Typhoon return to the skies!