By Anthony Liberatore

In Hildesheim, Germany, a replica of the Dornier Do X flying boat is taking shape and I had the privilege of interviewing the person who is spearheading this effort, Peter Kielhorn. The Dornier Do X flying boat was a technological marvel and an example of Germany’s aeronautical prowess from its conception by designer Claude Dornier in 1924 through its construction and test flight in 1929. With 3 aircraft built, it was formidable at 131 feet, 5 inches long, 156 feet, 10 inches in span, 12 engines in a push-pull configuration, and a gross weight of 108,027 lbs. Constructed in an era where external wires, biplane layouts, and wood for structures were still a norm, the Do X was relatively modern with its Duralumin construction, strut bracing with limited wires, and fuselage-mounted sponsons for water-borne stability. Sadly, while none of the 3 Do Xs that were built survived, a new chapter in the Do X’s history has begun. As noted by Peter, the team’s goal is to build a full-scale, buoyant non-flying replica that will be taxi-able on the water under electric power!

Peter Kielhorn is a software specialist who retired from Dornier Aircraft. Post-retirement, he was looking for some interesting opportunities. Peter’s first endeavor was to author the “Dornier Do 31,” which covers Dornier’s experimental VTOL (Vertical Takeoff and Landing) passenger transport aircraft. The Do 31 has the distinction of being the only VTOL to enter this arena, and the two that were built survive today in museums. Peter’s book can be found on Amazon in German only.

During our interview, Peter explains how his second opportunity evolved: “After finishing my book, I looked for my next challenge of what to do, and I decided to write about the Do X or the construction of the Do X, and this was in 2013 / 2014.” To make a physical replica of the Do X a reality is quite the undertaking and is a work in progress for the group called The Friends and Support Association Do X. As stated on their website: “The Friends and Support Association Do X E.V. was established on January 30, 2020, and is officially registered in the register of associations. The target of the Do X association in accordance with the articles of association is the rebuild of the Dornier Flying Ship Do X.” This entity holds legal status in Germany for volunteer organizations.

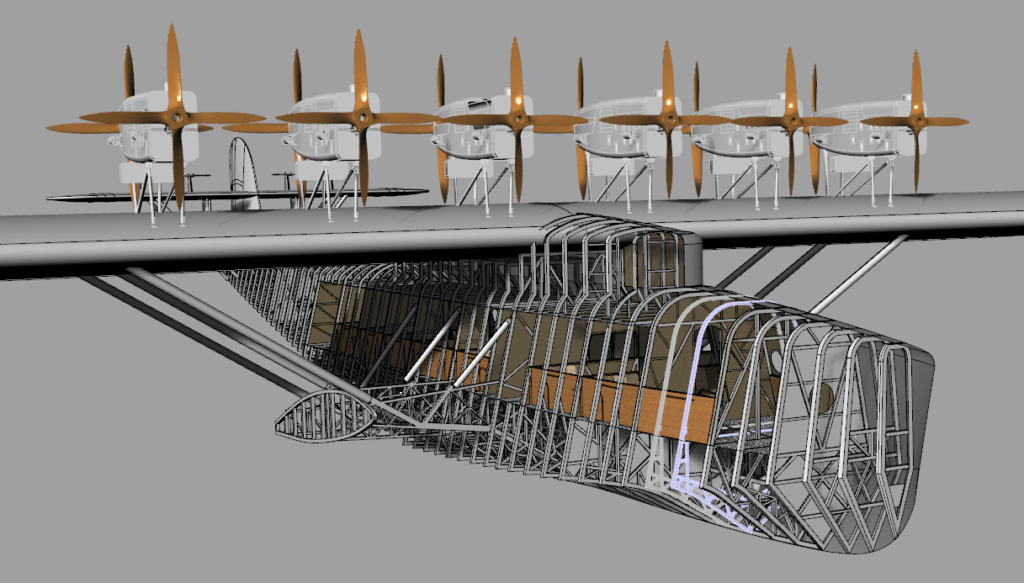

The Friends and Support Association Do X has taken volunteering and utilization of CAD and digital tools to the next level. As someone with a CAD background and a keen interest in the technology, Peter expounded upon what is on their website regarding what it took to make a digital Do X before any parts could be cut. The challenge was compounded by the fact that only 5 drawings remained in terms of historical records. The journey began with Peter approaching the Cooperative State Universities of Friedrichshafen in 2014. In 2018, the Cooperative State Universities of Lörrach and Mosbach joined in this effort. These prestigious institutions have a program where students must work on what we might call a ‘final project’ in the U.S. It was a win-win for both parties; sharp CAD-savvy young minds were given the opportunity to exercise their skills as part of an educational requirement, while Team Do X was able to populate their virtual Do X with much-needed product definition via the students’ efforts. Working from the limited scanned-in data (fuselage data) and imported scaled outlines, they created the external envelope as well as worked on the internal structure details. The students could use the CAD system they were most proficient in from the following options: Fusion 360, Inventor, NX, or CATIA to create solid models of the Do X. Up to this point, the students have contributed over 96,000 man-hours creating the digital data for this project, which is monumental.

As a side note, in drafting rooms of 40 years ago, scaling from a print was forbidden; however, in today’s world, scanning a PDF to use as a base of your initial sketches for models is acceptable. With these capabilities, the CAD world has become a very powerful tool for reverse engineering historical vehicles of all types. From here, the CAD files take some new roads to contribute to Do X project in many ways. First, they are converted to a “STEP” file, which allows it to be importable into other systems. In Team Do X’s case, it was imported into Rhino to create graphic files that can be utilized for marketing, fundraising, and more. On the physical replica side, the STEP files are imported into SolidWorks (a highly capable mid-range solid modeling tool), where the models are recreated, checked, and, if need be, corrected for any errors, since the SolidWorks models are utilized on the CAM (Computer Aided Manufacturing) side to machine the physical parts for the replica. The ‘and more’ I alluded to above is a story unto itself. The amazing graphic representation the team has created of the Do X has been honored and is now part of the Flight Simulator Legend Series and is now Legend Number 12!

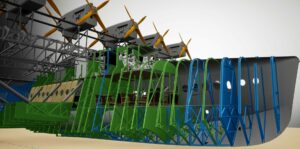

During my conversation with Peter, we discussed the progress of the Do X as they move toward their goal of completing the Digital Do X in 2026. The goal of completing the Replica is the 100th anniversary of the Do X’s first flight, which is July 12th, 2029. The image below denotes the progress via color coding. Gray is in the preliminary design phase, Yellow is ready for reproduction (ready to be sent to CAM for manufacturing), and Green has already been built. On the already built, Peter estimated that about 2% of the replica has been constructed up to this point. The parts completed can be seen on the website, and they will put into perspective how large of an aircraft the Do X truly is. On the docket in the next few months is to move the assembled components to Altenheim, Switzerland. The facility they will be moving into can accommodate the construction of this large aircraft, and with close proximity to Lake Constance, it makes the possibility of the floating and taxing of the Do X replica a reality.

This CAD model shows the current status of the pre-construction.

As you can see in the above graphic, a project of this nature is a herculean task. For those so inclined, Team Do X welcomes donors and sponsors to help them make their vision a reality. As the Do X website denotes: “Your support will be used to procure materials for the construction and to manufacture components for the overall construction.” Many thanks to Peter Kielhorn for being so gracious with his time for this article. For more information about this project, click HERE.

Born in Milan, Italy, Moreno moved to the U.S. in 1999 to pursue a career as a commercial pilot. His aviation passion began early, inspired by his uncle, an F-104 Starfighter Crew Chief, and his father, a military traffic controller. Childhood adventures included camping outside military bases and watching planes at Aeroporto Linate. In 1999, he relocated to Atlanta, Georgia, to obtain his commercial pilot license, a move that became permanent. With 24 years in the U.S., he now flies full-time for a Part 91 business aviation company in Atlanta. He is actively involved with the Commemorative Air Force, the D-Day Squadron, and other aviation organizations. He enjoys life with his supportive wife and three wonderful children.

![Gigi Coleman Performs Solo Show About African-American Aviation Pioneer 18 Gigi Coleman standing on the wheel of a Curtiss JN-4 "Jenny", built by Chapter 1414 of the Experimental Aircraft Association and the Vintage Wings and Wheels Museum, at Poplar Grove, Illinois in 2014. [Photo by Leonardo Correa Luna]](https://vintageaviationnews.com/wp-content/uploads/Gigi-Coleman-Polar-Grove-copyright-Leonardo-Correa-Luna-2014-150x150.jpg)

“…Dornier’s experimental VTOL (Vertical Takeoff and Landing) passenger transport aircraft. The Do 31 has the distinction of being the only VTOL to enter this arena…”

The Fairey Rotodyne was a VTOL passenger transport, several years before the Do 31. The Rotodyne was much bigger and could carry many more passengers. It achieved VTOL using a large rotor that was disengaged in forward flight to autorotate.

On a more practical note, Sikorsky built a passenger airliner versions of the S-61 that was in airline service for several years.

Hello, could you please forward me Peter Kielhorn’s email address? I’ve constructed an aluminum full-scale replica of a DeHavilland Comet 1 nose section, and a full-scale AVRO Vulcan flight simulator. It seems Peter and I are on the same path for building replicas of aircraft that no longer exist. I can provide photos. Thank you.