Warbird Digest has just received the June/July, 2021 report from Chuck Cravens concerning the restoration of the Dakota Territory Air Museum’s P-47D Thunderbolt 42-27609 at AirCorps Aviation in Bemidji, Minnesota. We thought our readers would be very interested to see how the project has progressed since our last article on this important project. So without further ado, here it goes!

Update

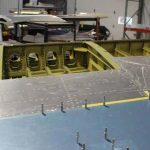

Much of the work this month doesn’t reveal obvious visual changes to the airframe’s exterior, because a great deal of recent effort has involved systems preparation and installation. In a complex fighter like the P-47 – with all of its turbo ducting, engine controls, turbosupercharger, plumbing, and landing gear hydraulics – the behind the scenes elements of the restoration are very time consuming.

Turbosupercharger

One of the unusual facets of this restoration is the incorporation of a functional turbosupercharger system. This involves significant additional effort and resources to make the system operational, but the Dakota Territory Air Museum feels that it is worth taking these extra steps in the name of authenticity.

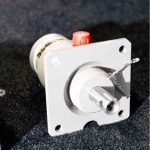

Hydraulics

Mark has been restoring and inspecting the complex components of the landing gear and flap hydraulic systems.

Christmas Tree Tank Plumbing

Aaron has completed the final items of the unique Christmas tree tank installation. This was a particularly challenging aspect of 42-27609’s restoration because none of the details regarding this installation are documented in any known Republic engineering drawings. This lack of original manufacturing drawings isn’t unusual for field modifications such as this auxiliary tank, so Aaron had to follow the way things were done in 1944 by carefully examining and documenting 42-27609’s modified fuselage systems during their disassembly for inspection.

All of the radio and oxygen equipment which normally would have sat where the Christmas Tree Tank ended up had been moved as part of this field modification, so finding new locations for their installation – in places not documented on Republic drawings – was also a significant part of this process.

Oxygen

The oxygen tank installation is another non-standard aspect of the restoration, because of course the wartime modification’s crew moved them further aft in the fuselage to provide space for the Christmas Tree Tank.

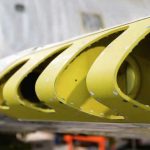

Flaps

Cory continued working on producing a set of flaps for the P-47 this month.

Mock Up Engine

A non-airworthy R-2800 is being used as a placeholder for installing as many of the engine accessories and connections as possible before the rebuilt engine comes in.

The P-47D-22 and -23 Represented the Pinnacle of Razorback Thunderbolt Design

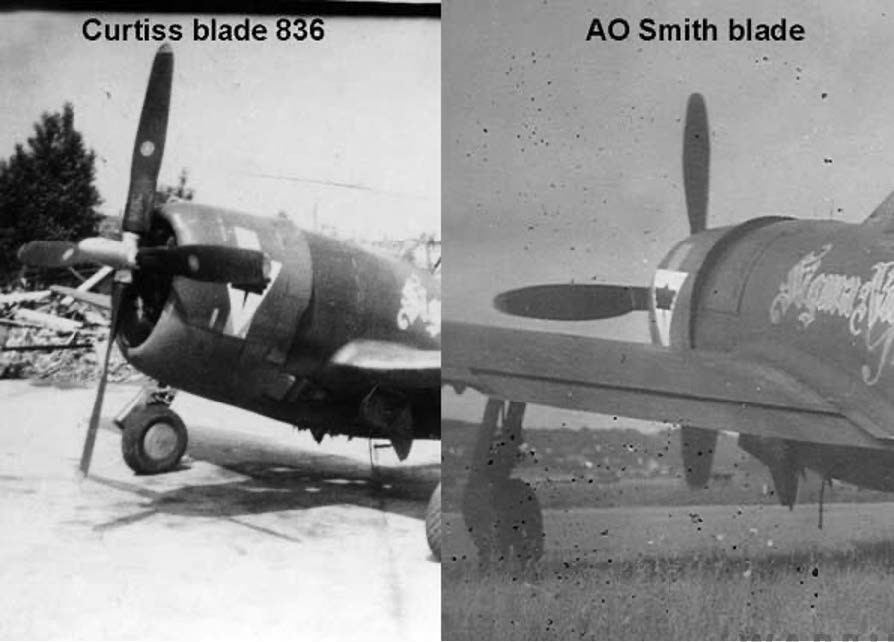

The last two versions of the razorback P-47 were very similar, and they introduced the paddle blade propellers to the Thunderbolt line. They differed from one another primarily in the propeller used and the location where they were manufactured. The P-47D-22 RE was a Farmingdale product, while the -23 was built in Evansville.

The P-47D-22RE used a Hamilton Standard Hydromatic 24E50-65 propeller that was 13 ft 17/8 in diameter. The P-47D-23RA incorporated a Curtiss Electric C542S of 13 ft. 0 inch diameter1 and used either Curtiss paddle blades or AO Smith blades that were even wider.

These props allowed full use of the increased horsepower available with water injection.

Joe Baugher reports “ there was a scant six inches of clearance between blade tips and the ground during take-offs and landings, which must have been hair-raising!”

1 Roger Freeman, Thunderbolt, a Documentary History of the Republic P-47, Charles Scribner’s and Sons, New York, 1978, p119

The -22 and -23s both added a jettisonable cockpit canopy. The pilot pulled a ring inside the cockpit, the hood would then be pushed backward, and the slipstream would then finish the job of pulling the canopy free of the aircraft. Other updates included the addition of a bullet-proof windshield, and an increase in the internal fuel capacity.2

Both had better climb by about 400 feet per minute than previous versions of the P-47. The D-22 had very slight performance advantages over the D-23, but they were small enough that the individual airframe differences are more significant.

2 Joe Baugher,Aerofiles P-47D/G Thunderbolt, http://www.aerofiles.com/JBrepub-p47dg.html, website accessed August 3, 2021

Below is a War Department, Engineering Department report on testing of P-47D-22 42-26167 at Wright Field in Dayton, Ohio.

ENGINEERING DIVISION MEMORANDUM

REPORT SERIAL NO. ENG-47-1774-A

15 July 1944

FLIGHT TESTS ON THE REPUBLIC

P-47D AIRPLANE, AAF NO. 42-26167

USING 44-1 FUEL

Summary

Preliminary tests were run to clear the airplane for performance with higher powers with and without water injection. Detonation equipment was installed to determine if any flight condition became marginal as to detonation, cooling or improper operation of auxiliary parts. No detonation was observed in level flight up to 65.0″ Hg. without water and 70.0″ with water. No detonation was observed in climb up to 65″ Hg. without water. Detonation occurred at 65.0″ with water in climb but was remedied by using a No. 18 water jet. Cylinder head and carburetor air temperatures remained below the limits in level flight. Excessive cylinder head and carburetor air temperatures were encountered in climbs, limiting the duration of any climb to a point where limits are reached.

The airplane and engine handled well at all altitudes at the higher powers. At 70.0″ Hg., water injection, a maximum speed of 444 MPH was obtained at 23,200 feet. At 65.0″ Hg., with water a high speed of 439 MPH at 25,200 feet and a maximum rate of climb of 3260 ft/min. at 10,000 feet were obtained. At 65.0″ Hg., without water a high speed of 430 MPH at 25,400 feet and a maximum rate of climb of 2850 ft/min. at 12,000 feet were obtained. At 56.0″ Hg. without water a high speed of 418 MPH at 29,600 feet and a maximum rate of climb of 2330 ft/min. at 12,000 feet were obtained. At 52.0″ Hg. without water a high speed of 412 MPH at 31,400 feet and a maximum rate of climb of 2030 ft/min. at 12,000 feet were obtained.

And that’s all for this month. We wish to thank AirCorps Aviation, Chuck Cravens for making this report possible! We look forwards to bringing more restoration reports on progress with this rare machine in the coming months. Be safe, and be well