WarbirdsNews has just received the latest report from Chuck Cravens on the restoration of Texas Flying Legends Museum’s P-47D Thunderbolt 42-27609 at AirCorps Aviation in Bemidji, Minnesota. We thought our readers would be very interested to see how the project has progressed since our last article on this important project. So without further ado, here it goes!

Texas Flying Legends P-47D-23RA – March/April 2018 Report

By Chuck Cravens

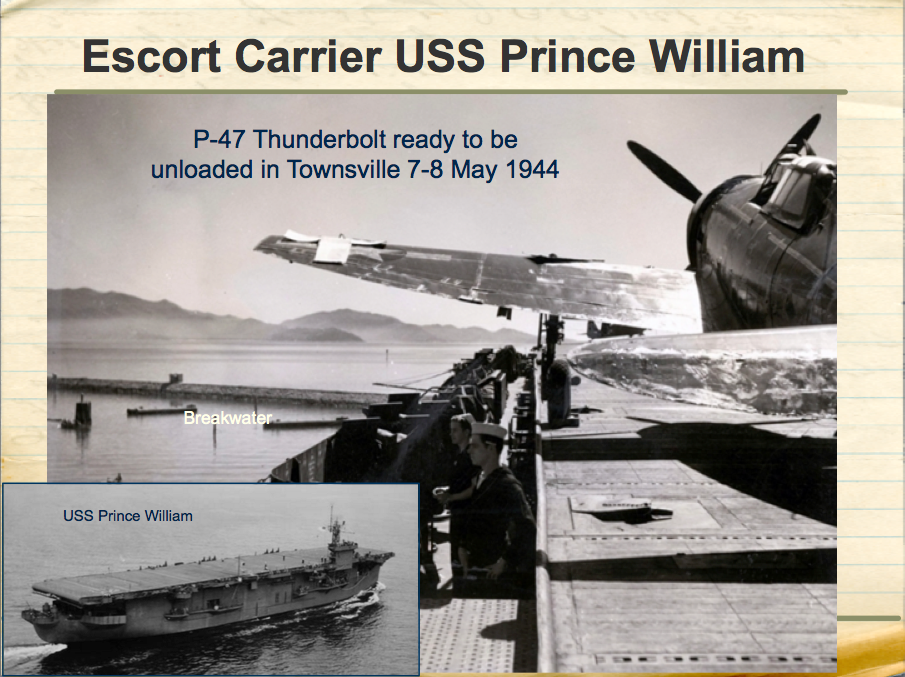

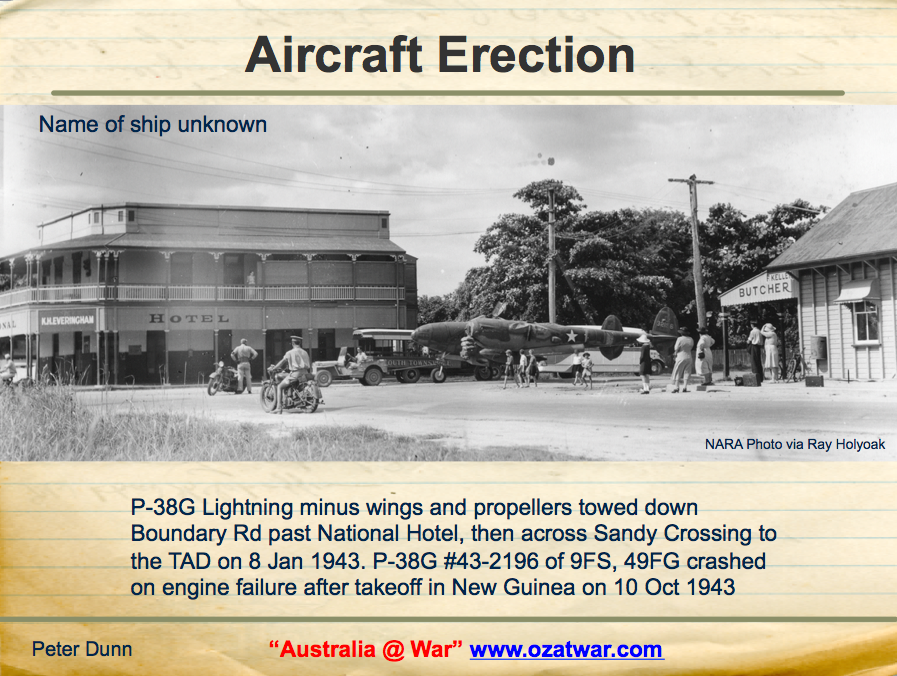

AirCorps Aviation received some fascinating images showing Republic P-47s arriving in Australia aboard the carrier USS Prince William on the very same day and ship which the Thunderbolt they are restoring is said to have arrived!

This photo shows the carrier USS Prince William on the very day 42-27609 arrived at Townsville. It is exciting to have an image that relates to the Texas Flying Legends Museum’s restoration project so specifically. Our Thunderbolt was on that deck somewhere when the photo was taken! The P-47 pictured could even be our project covered in cosmoline, but without a clear view of the tail number it is impossible to know.

As the caption notes, Peter Dunn, of Brisbane, Australia provided these photos. He described how the incoming fighters were transported to the Air Erection Depot for the task of making them airworthy and ready for combat in his e-book, Townsville Air Depot.

As Peter Dunn notes in his recently released book, Townsville Air Depot, “Aircraft that could be towed by Jeeps from the Townsville Harbour to the Aircraft Erection Depot were towed along Boundary Road, past the National Hotel and then across the Causeway. Typically when partially assembled aircraft arrived at the Aircraft Erection Depot, engines were cleaned of cosmoline, a brown coloured wax-like corrosion inhibitor, wings and propellers were attached where needed, guns and radios were installed, landing gear and engines were checked and the aircraft was fuelled and test flown. The aircraft were then lined up and eventually assigned to an operational squadron. The Aircraft Erection Depot, which was built as Project 1, was later absorbed into Depot No. 2 when it became operational. Construction of Depot No. 2 started in October 1942”

Update

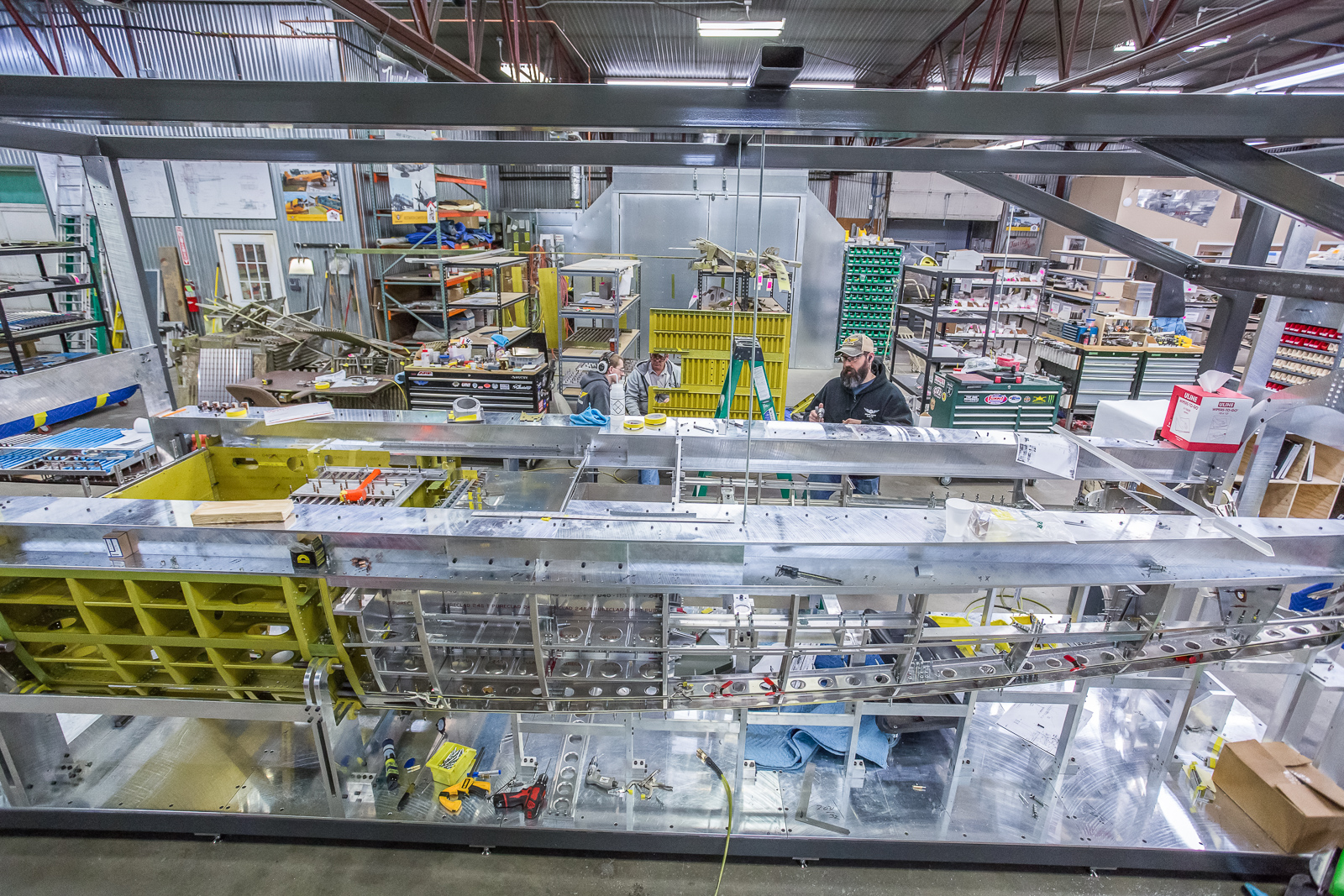

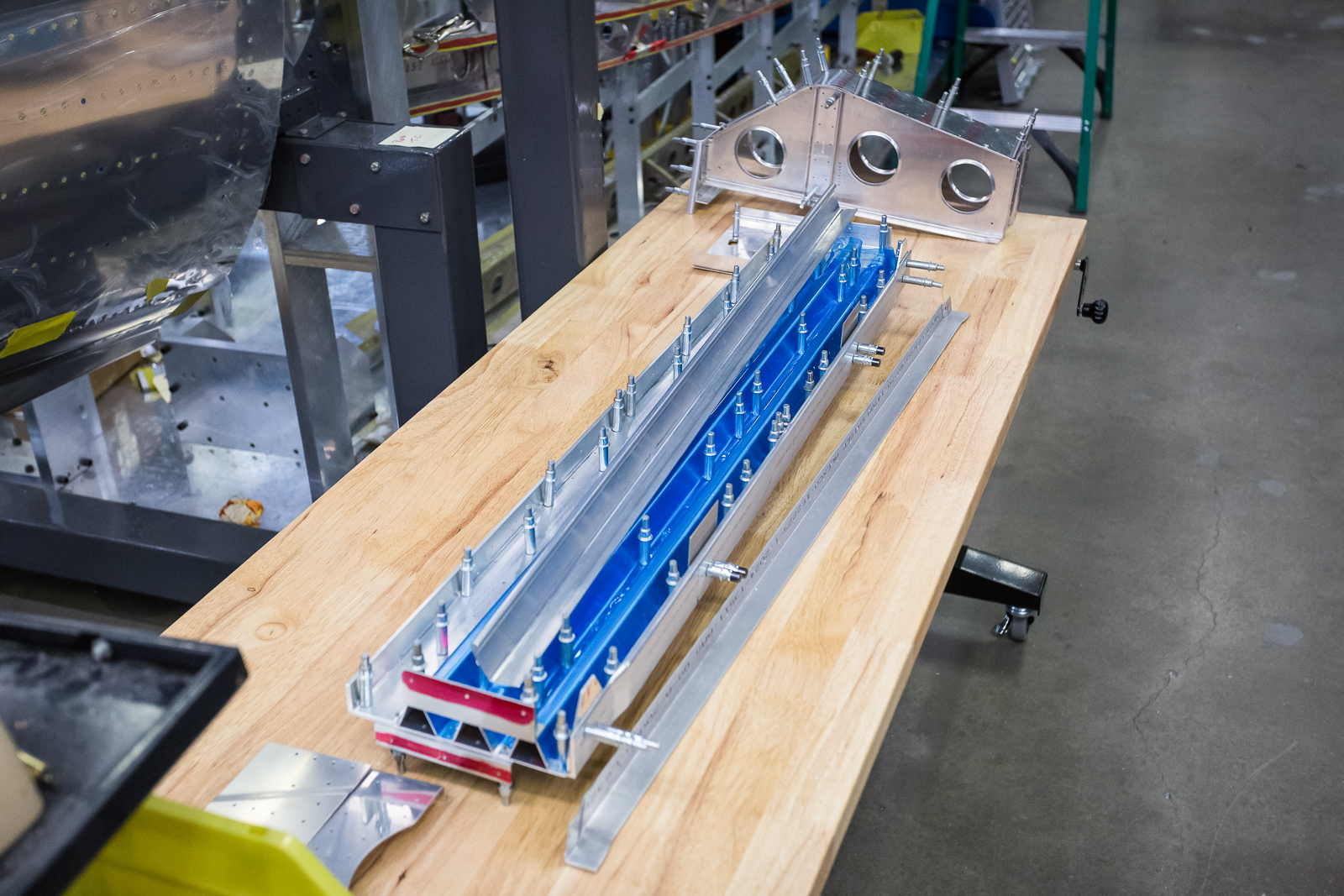

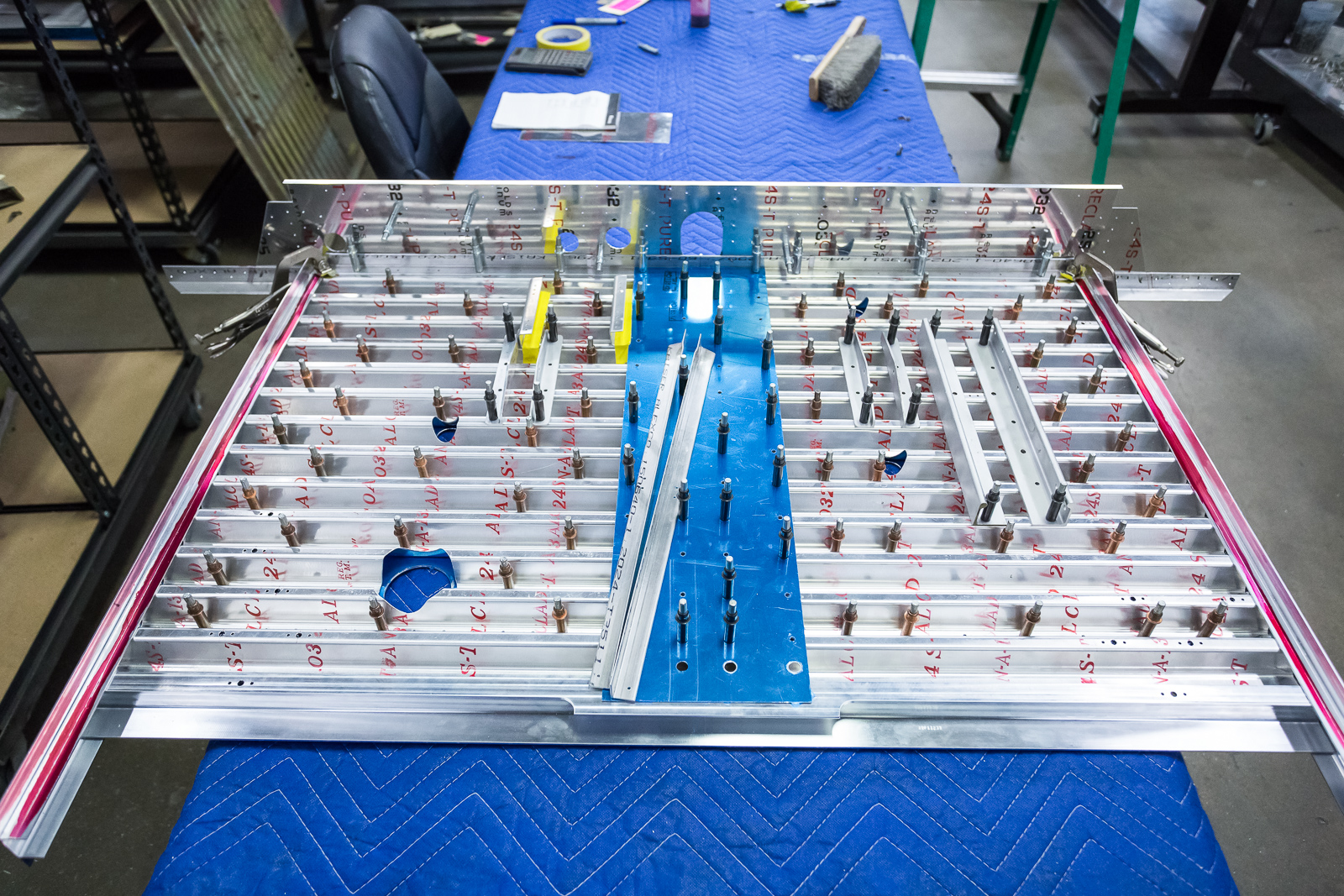

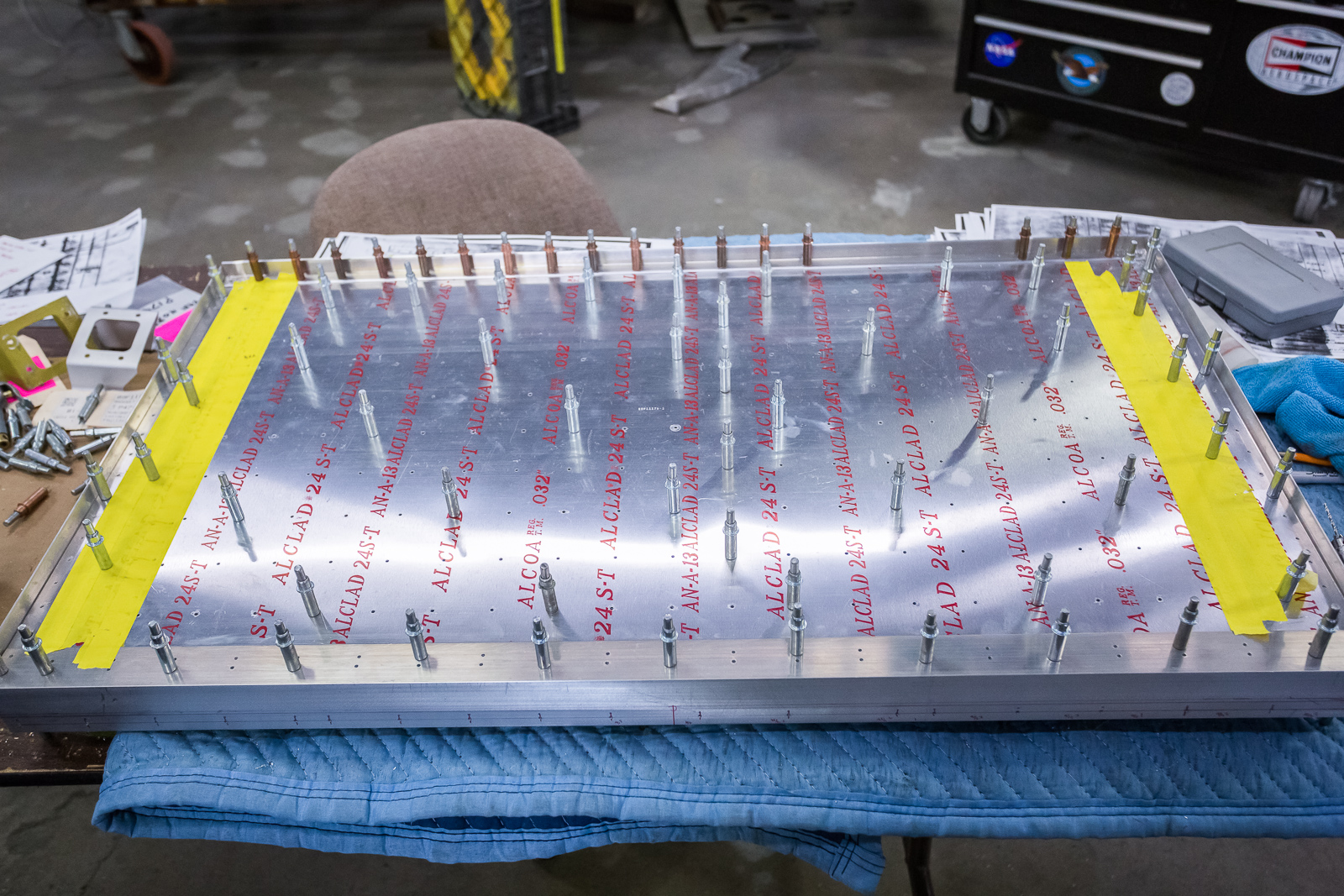

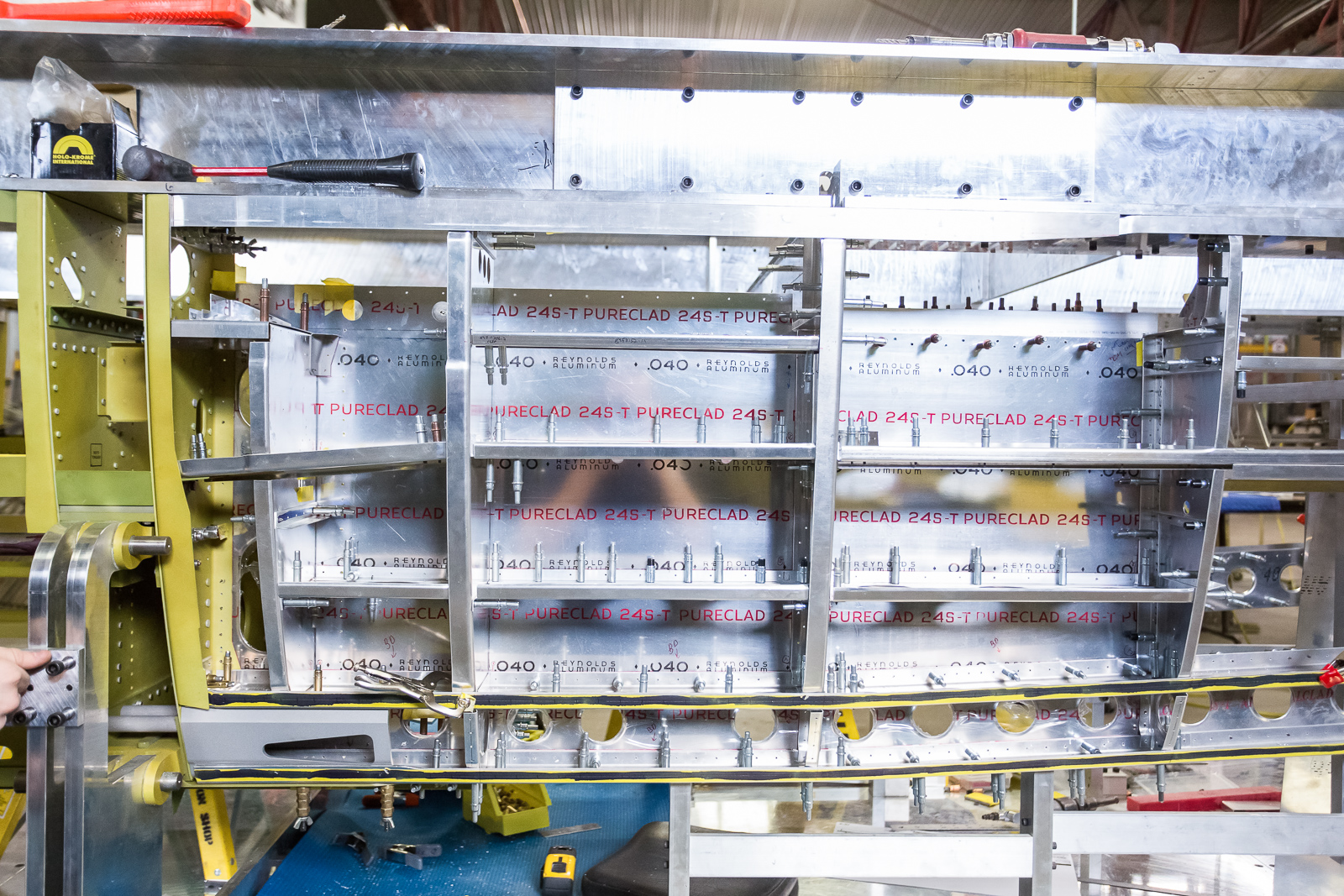

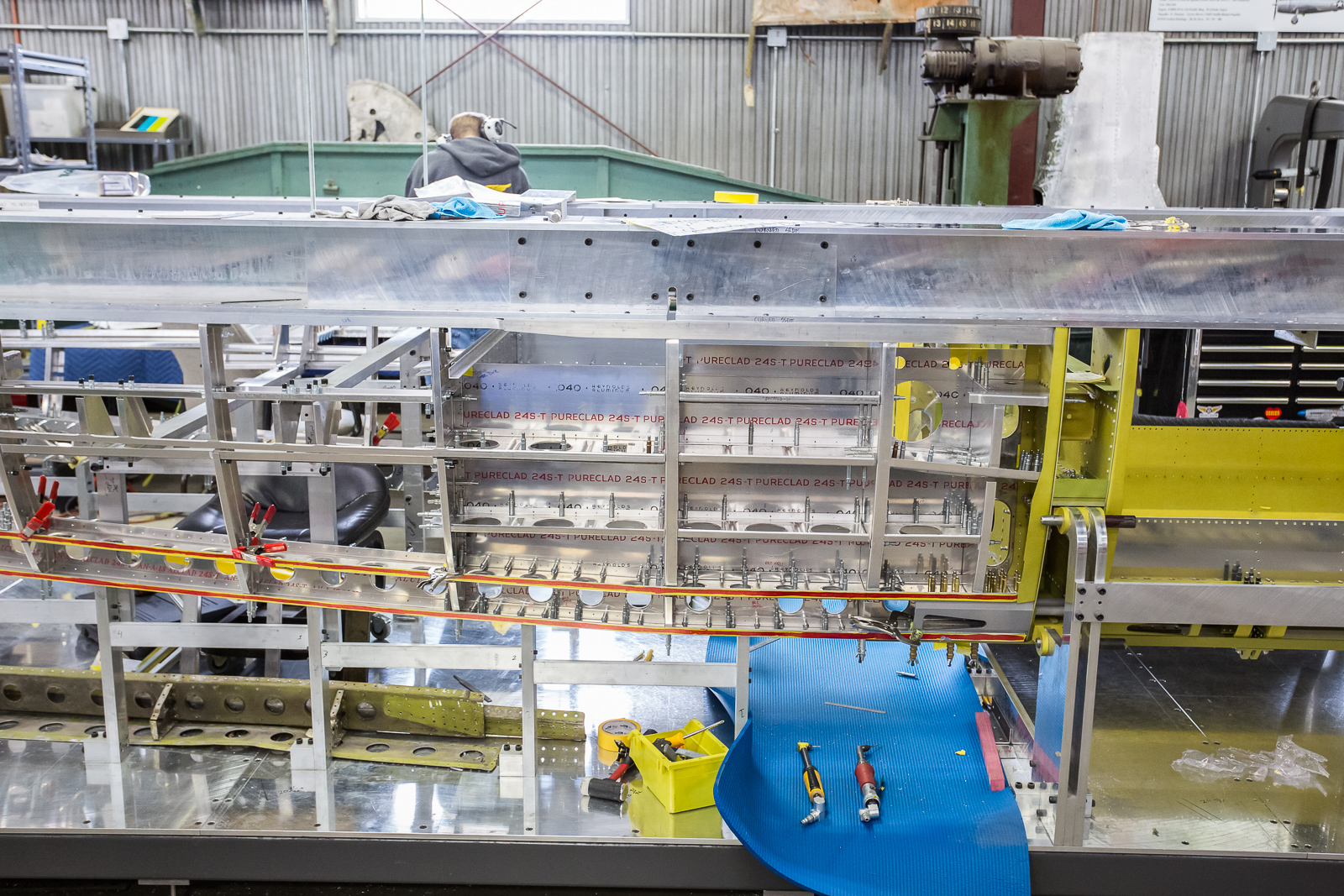

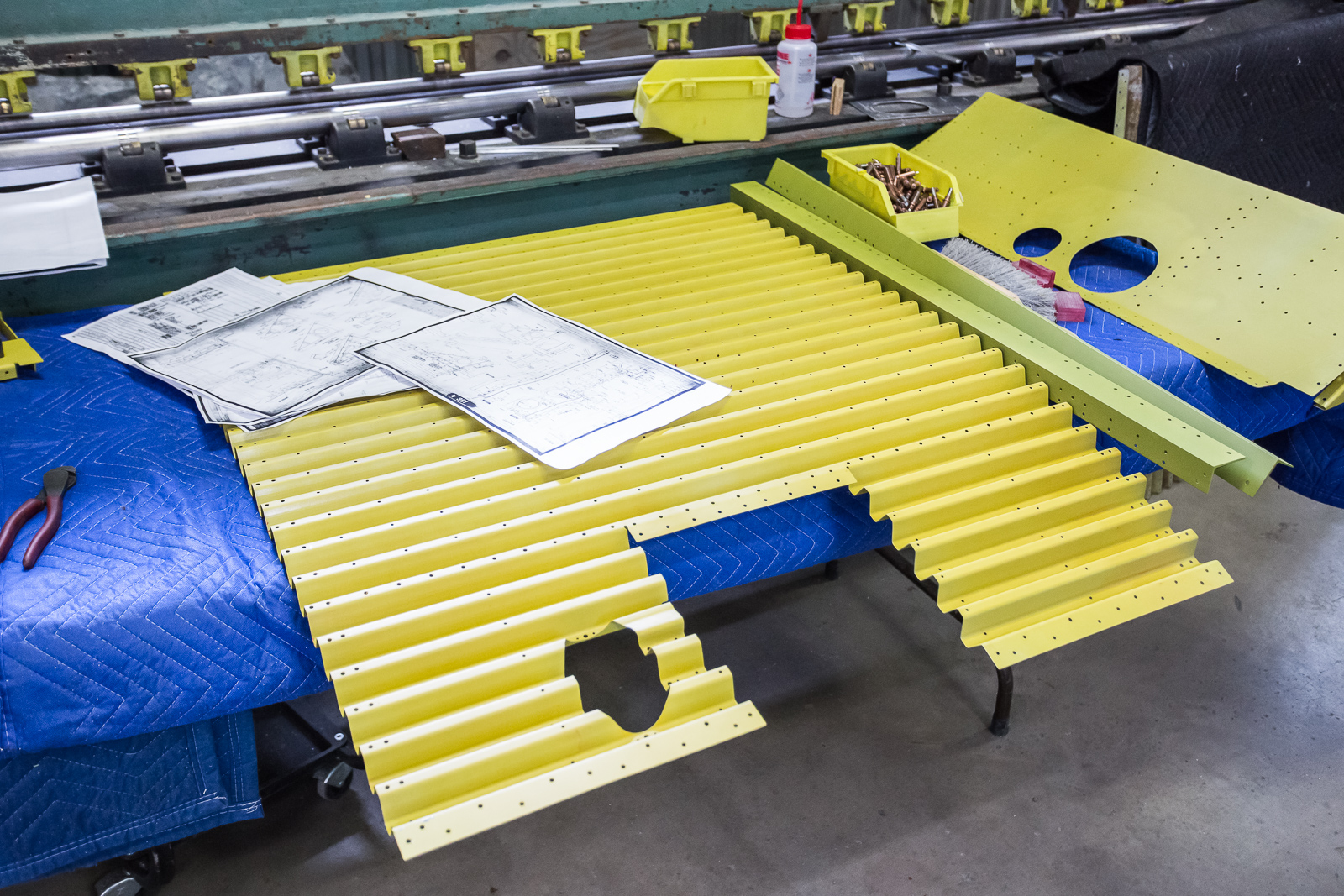

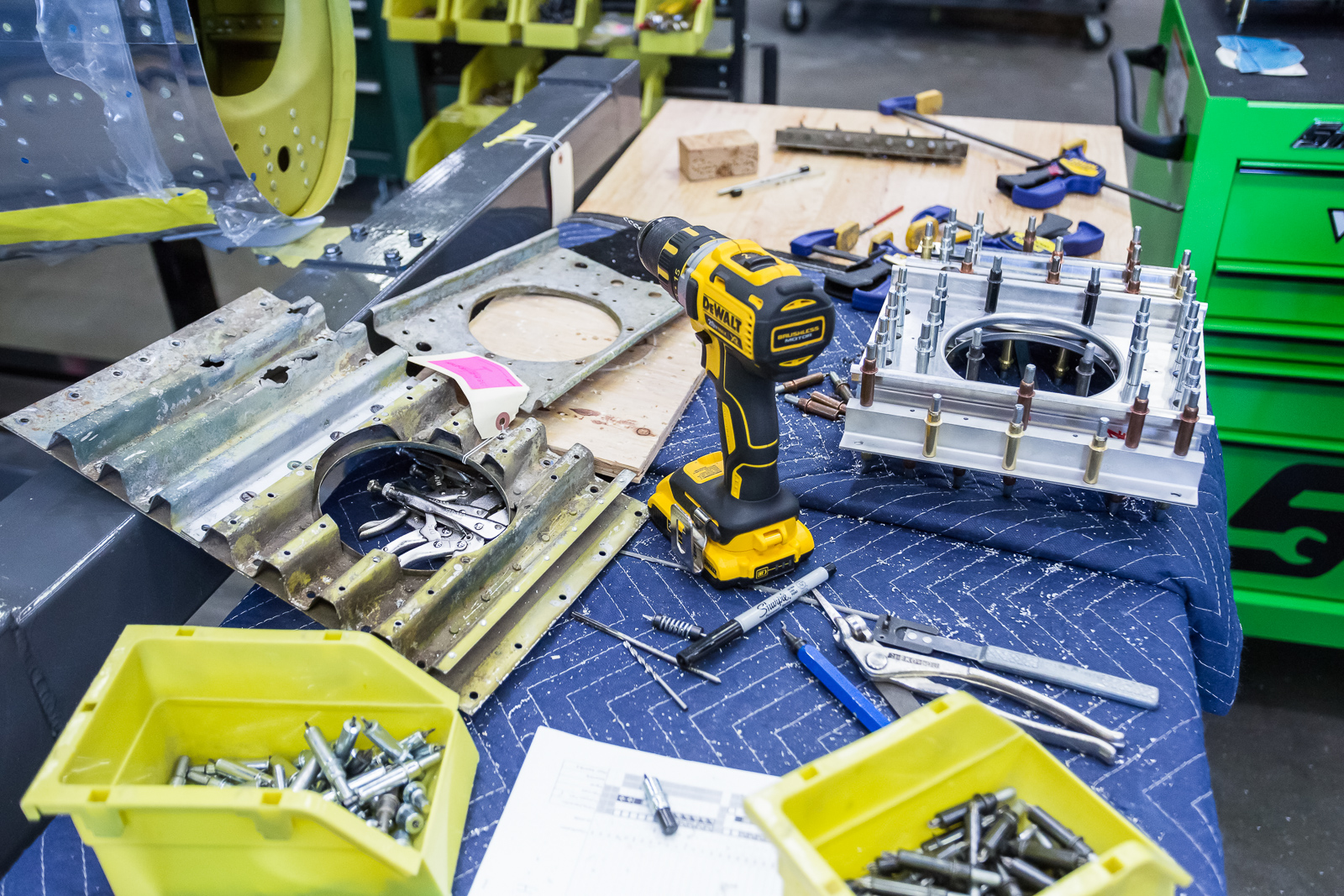

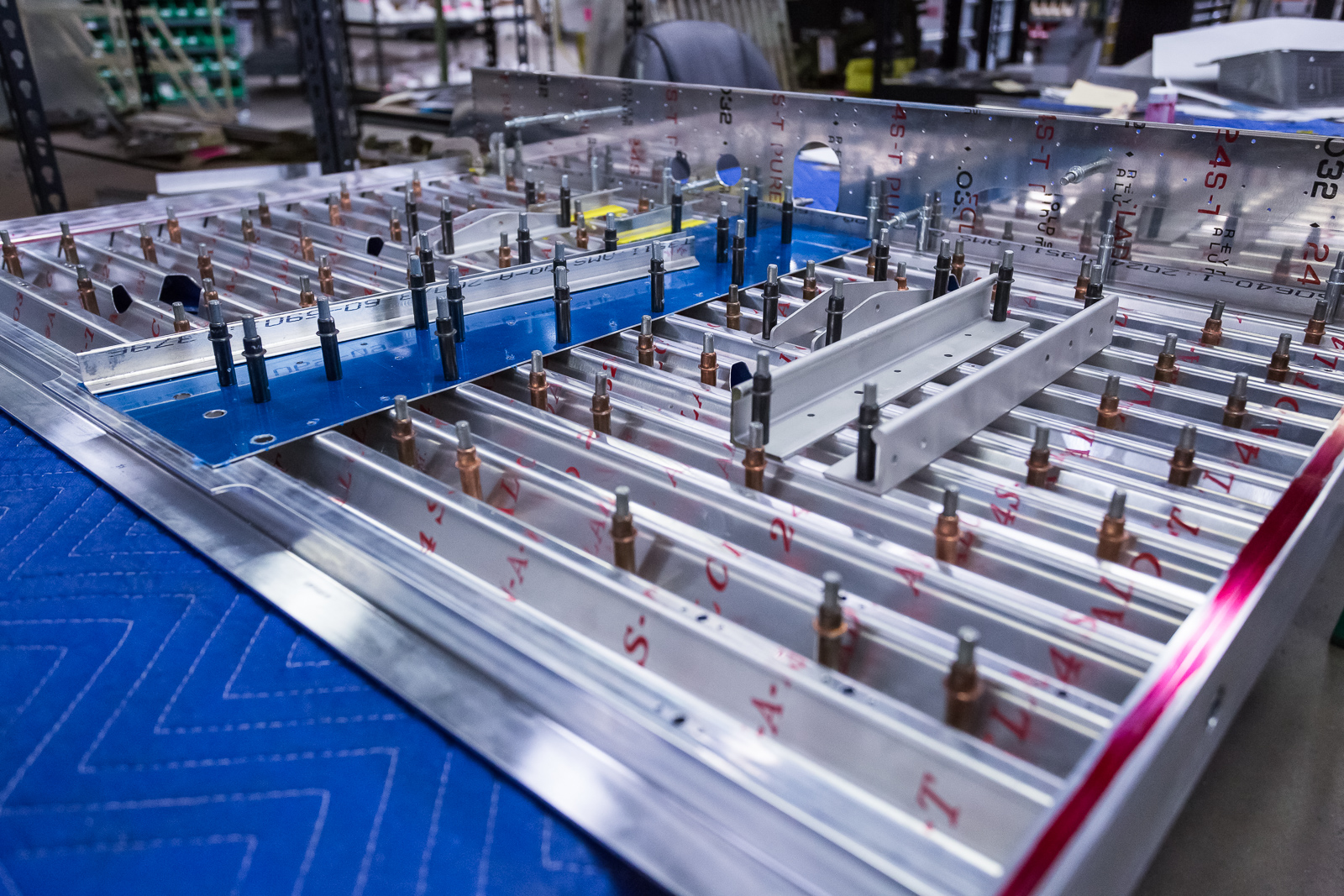

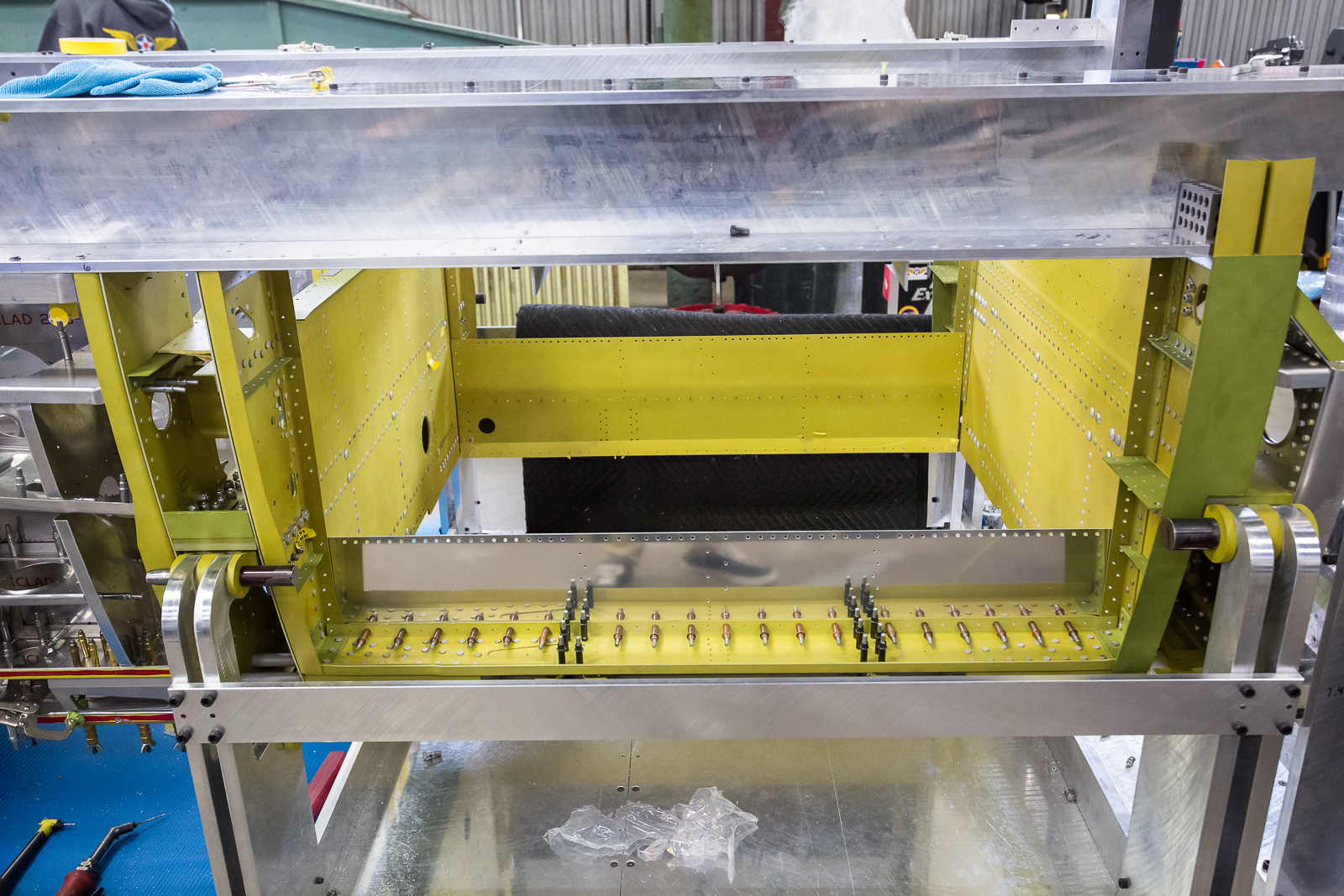

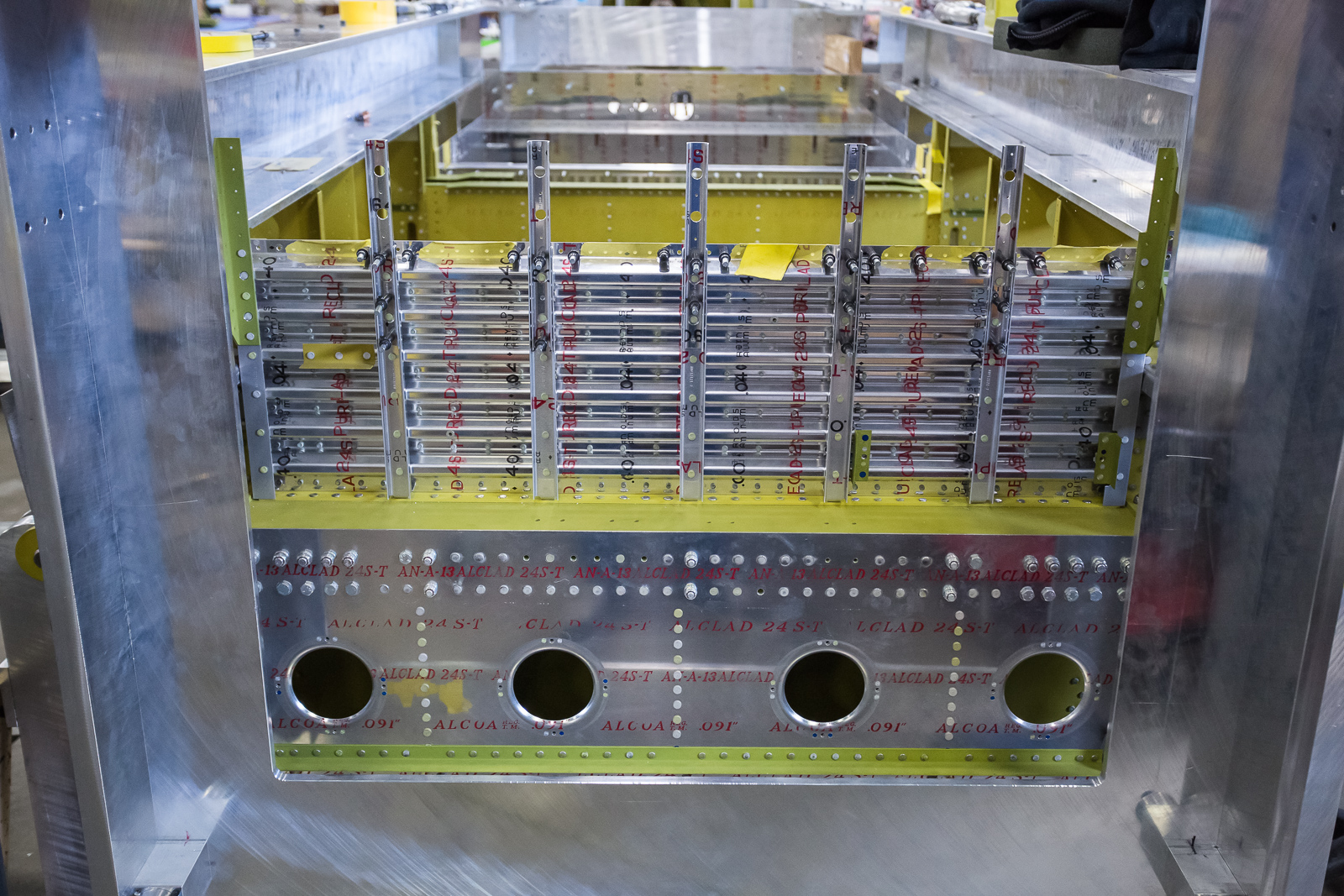

It was great to receive the wartime photos related to our P-47. Meanwhile, back on the restoration floor at AirCorps, the fuselage continued to take shape. This month we will show some of the work on the pilot’s floor and the fuel tank bay structure that it mounts to.

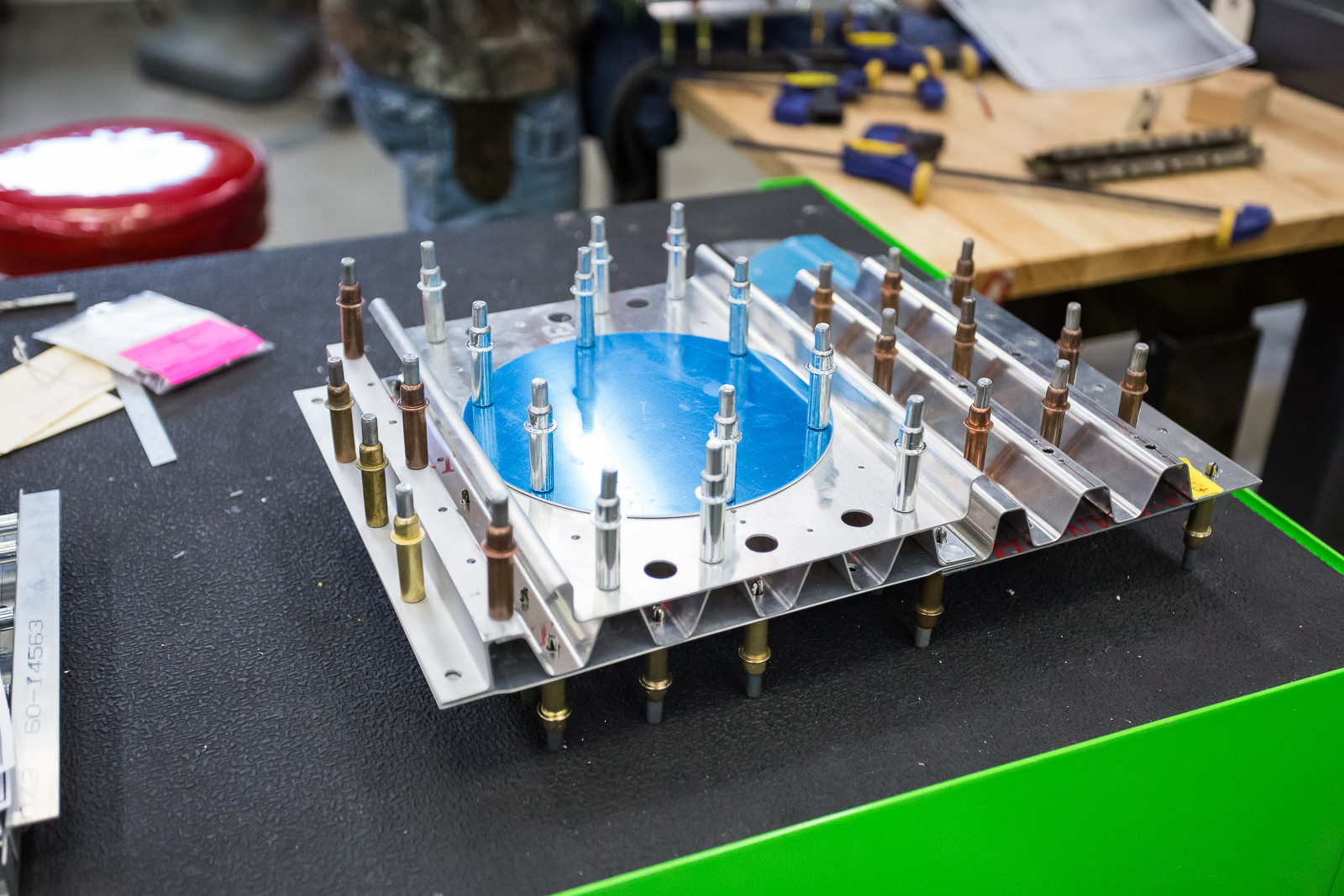

This section is installed to the right side of the stick assembly, the one with the fuel selector goes on the left side. The “Z“ channel extrusion on the far left of the assembly is one of the original parts of 42-27609 that passed inspection and has been reused in the restoration. After 70 years in a wet tropical climate, there aren’t a great many usable parts, but every one that can be used will be.

It is the floor under the pilot seat and the shorter brackets visible in this shot are lower pilot’s seat tube supports. The longer aluminum angle brackets are for the emergency hydraulic hand pump.

The main internal fuel tank on a P-47D-23 had a capacity of 205 US gallons. That makes the total internal fuel capacity 305 gallons (without drop tanks).

In the Southwest Pacific, some were fitted with a tank behind the cockpit. That field installation was commonly called a “Christmas tree tank” because of its shape. Ours was one of those and the fuel cell is labeled “capacity 42 US Gallons” so, in total, it could have flown with 347 gallons internally.

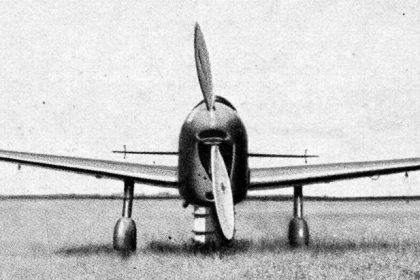

In a phone interview he graciously granted, Southwest Pacific P-47 pilot Major General DeWitt R. Searles commented on the Christmas tree tank: “Yes, I remember the in-theater installation of the fuel tanks behind the pilot to give us a little better range. We were warned to avoid high G maneuvers until the tank was completely empty as the weight of a full tank would upset the aerodynamic balance which could lead to a loss of control. The P-47 was the sturdiest and most stable propeller driven aircraft that I have ever flown. It had an almost unlimited diving speed. I don’t recall a single incident of one breaking up in flight because of aerodynamic stress. And it could absorb more hits by enemy fighters or ground fire, and keep flying, than any other fighter plane that I know of. It’s versatility was not fully exploited until late in the war, in Europe and the Pacific, after enemy fighter strength had been severely reduced or eliminated. Then we found out that we had the most rugged and effective fighter bomber ever built. With eight fifty caliber machine guns and a 2000 pound bomb loads it was unmatched as an air to ground fighter aircraft.”

The next model of the P-47, the D-25, not only had a bubble canopy, but also had additional fuselage fuel tank capacity that brought its internal fuel load up to 370 gallons.

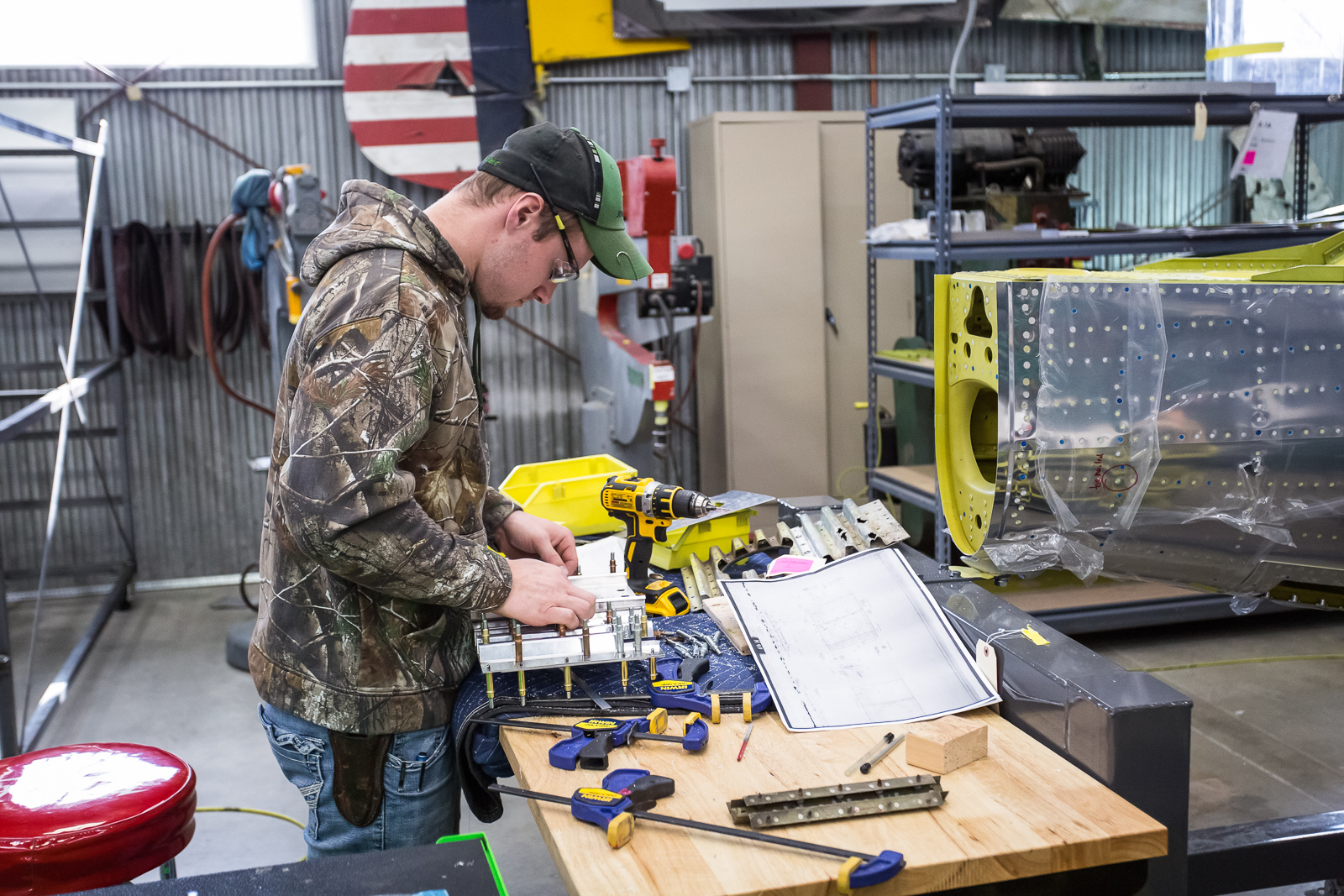

I mention the guys working on our projects in photo captions all the time, so I thought it would be a good thing to occasionally include a little more about them. I think Randy has been in more update photos than anyone, so he was a easy choice for the first shop spotlight.

Randy was born in Bemidji and has spent most of his life here. He has four kids and worked as a carpenter for the twelve years before joining AirCorps Aviation.

Randy’s proven craftsmanship made him a perfect fit for AirCorps. When he started in 2014, the company was expanding and Randy adapted his skills quickly to the aircraft restoration arena.

Randy says is favorite warbird is the P-51, but the P-47 is growing on him!

And that’s all for this month. WarbirdsNews wishes to thank AirCorps Aviation, Chuck Cravens (for the words) and John LaTourelle (for the images) for making this report possible! We look forwards to bringing more restoration reports on progress with this rare machine in the coming months.