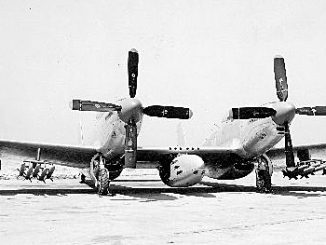

WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia, and we thought you would all be pleased to see the latest progress! As we mentioned in our last update in early July, since the project is coming very close to completion, there are fewer major accomplishments that can be photographed, which means that our usual monthly reports will happen more infrequently, hence the two month gap since the last posting. This does not mean that plenty isn’t happening on the resurrection of XP-82 Twin Mustang 44-83887, just that only some of it can be documented easily. This restoration update will mostly consist of a photo-essay with captions to show which areas have been receiving attention most recently.

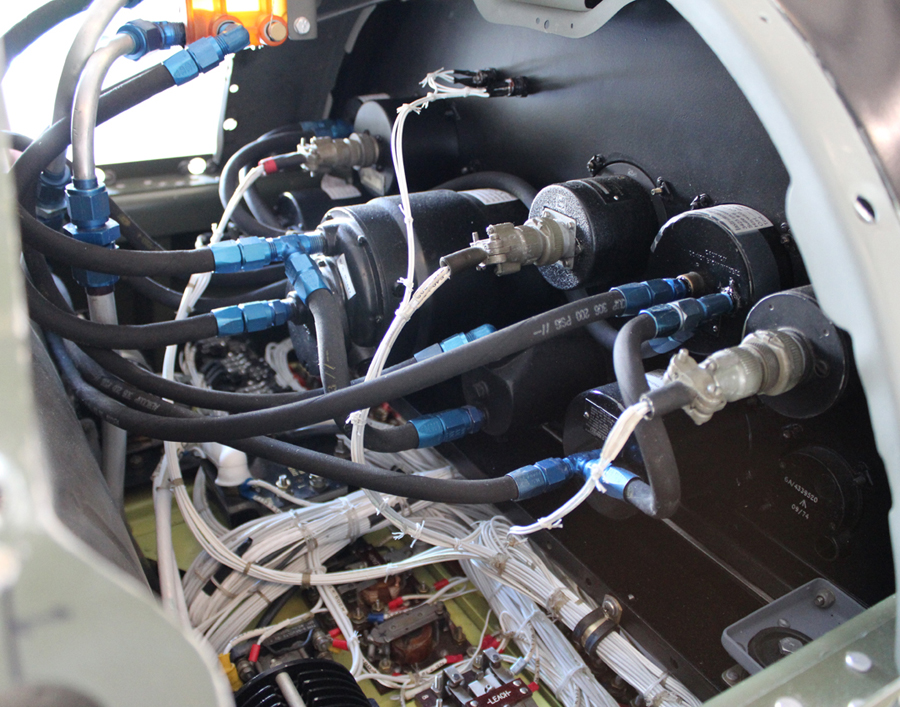

Cockpit Instrument Panels

Wingtip Lighting

Gear Doors – Two Main & Four Tail

A job that Tom Reilly thought would be very difficult, pressing the two inside waffle skins, turned out to be a very quick and efficient job that came out perfectly within three weeks. Two team members completed all of the interior framework, including the installation of the up-lock latch forgings (two per door) along with the two flat exterior skins.

Reilly took the two main gear doors, along with the four tail wheel doors to Kermit Weeks’ facility in Polk City, Florida for spot welding. With these six doors completed, that completes 99.9% of the sheet metal work on the XP-82. The only remaining sheet metal items are the two outboard gear doors and the adjoining lower engine close-out fairings that cannot be completed until the team ascertains the exact curvature and pattern off each outboard door. The project is waiting for these two outboard doors to be delivered.

Pat Harker supplied the project with four tail gear door interior pressings. Within a few days these two team members had them fitted to the eight installed hinges with the newly formed outside skins. These outside skins are now spot welded to the inside pressings.

Engine Exhaust Fairings

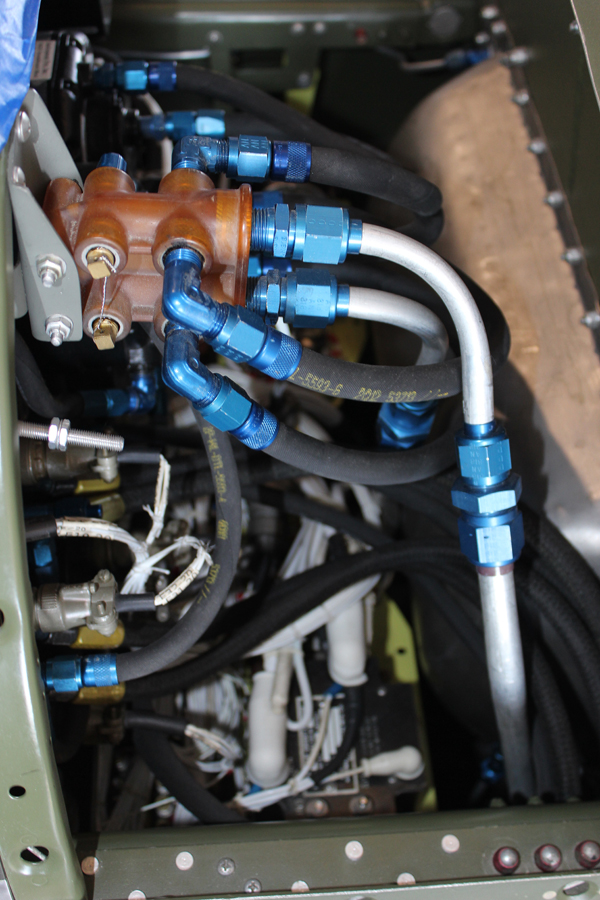

Carburetor Air Induction System

The final installation of the rotating barrels, located underneath each spinner that control the air induction temperatures, and all of the induction trunks back to the carburetor inlets are now completed. The only thing to remaining to be done on these induction systems are the rod and lever mechanism adjustments that open the hot air doors for carburetor heat.

Engine Run

In a major restoration landmark, Tom Reilly and his team pulled the XP-82 out onto the ramp, tied down both tails and chocked both main wheels and started both engines simultaneously for the first time. Reilly initially ran them at idle for about two minutes, until the oil and coolant temperatures rose, and then he brought both engines up to a little over 1000 rpm (not fast enough to check generator or propeller functions). All of the fuel, oil, tachometer and associated temperature gauges worked as expected.

And that is all for this month’s report.

Many thanks again to Tom Reilly for this update. You can learn more about the project on their blog HERE. Although we are not exactly sure when the next formal update will come, please be sure to check back with WarbirdsNews in a couple of months for the next installment in the story following the XP-82′s road to recovery!

Related Articles

XP-82 Twin Mustang – August, 2017 – Restoration Update

XP-82 Twin Mustang – June, 2017 – Restoration Update

XP-82 Twin Mustang – May, 2017 – Restoration Update

XP-82 Twin Mustang – March/April 2017 – Restoration Update

XP-82 Twin Mustang – February/March 2017 – Restoration Update

XP-82 Twin Mustang – January 2017 – Restoration Update

Richard Mallory Allnutt's aviation passion ignited at the 1974 Farnborough Airshow. Raised in 1970s Britain, he was immersed in WWII aviation lore. Moving to Washington DC, he frequented the Smithsonian’s National Air & Space Museum, meeting aviation legends.

After grad school, Richard worked for Lockheed-Martin but stayed devoted to aviation, volunteering at museums and honing his photography skills. In 2013, he became the founding editor of Warbirds News, now Vintage Aviation News. With around 800 articles written, he focuses on supporting grassroots aviation groups.

Richard values the connections made in the aviation community and is proud to help grow Vintage Aviation News.

Be the first to comment

Graphic Design, Branding and Aviation Art