As usual, WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this month!

September was another incredible month for accomplishments at the XP-82 restoration shop!

Tail Sections: For the majority of the past month, most of the crew has been focused on the final alignment and attachment of the aft fuselage extensions, the vertical stabilizers and the horizontal stabilizer. The initial lineup went perfectly, but the fine adjustments down to a precision of .010″, or 3 times the thickness of a cellophane sheet, seemed to have taken forever. However, everything is now permanently aligned and attached, and the team has started the final fitting and riveting of the side skins.

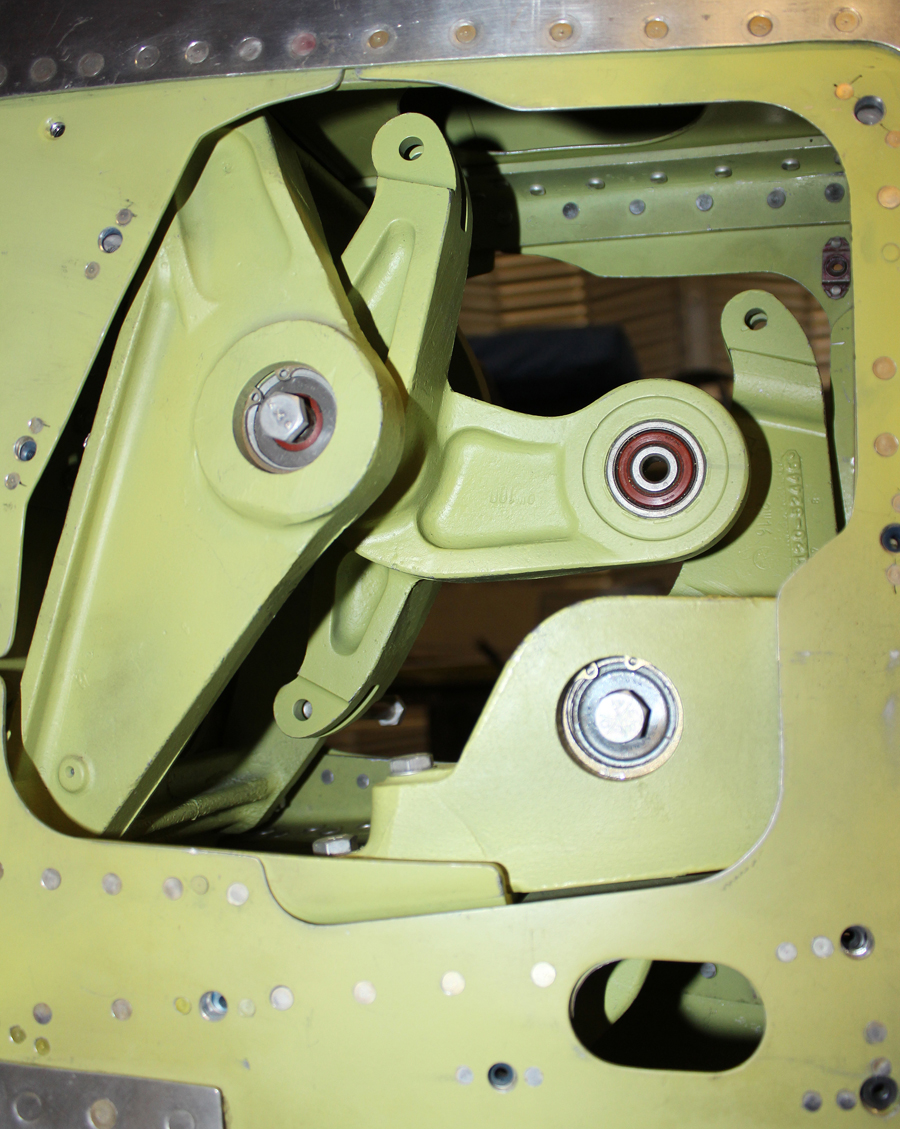

The pulley brackets for all of the primary controls (elevator and rudder), and secondary (trims) are now completed and awaiting final installation along with the four side skins. All four of the elevator and rudder mount castings and associated matching bell cranks are in place.

Both dorsal fins are well on their way to completion. Reilly’s team had to make a few ribs and attachment parts, but the alignment and installation of the dorsals went smoothly.

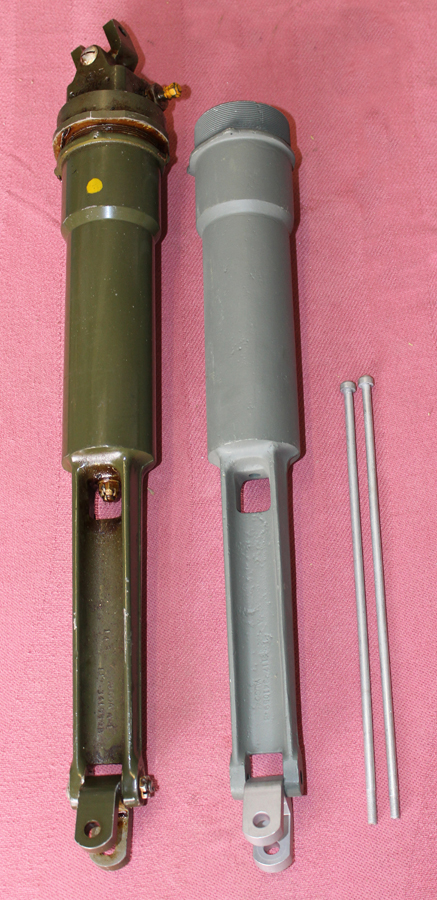

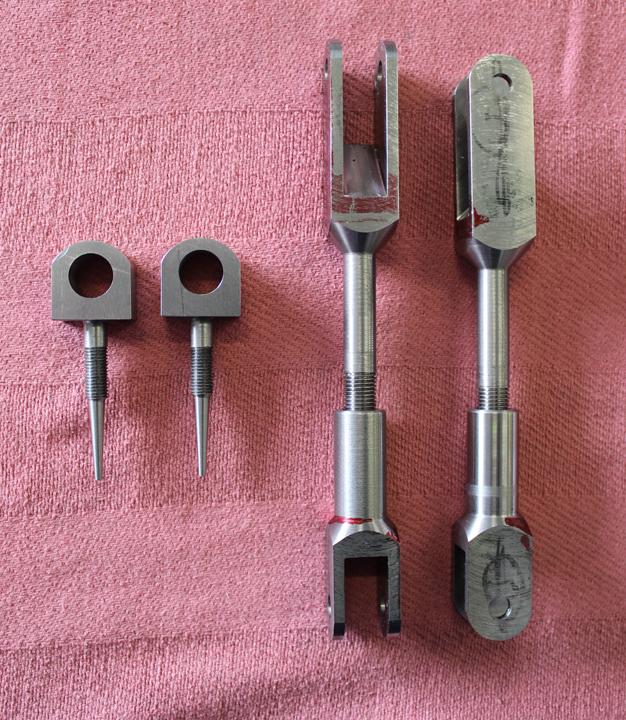

Two other team members have been restoring the multitude of tail wheel gear parts. One cannot believe how many moving parts are in the XP-82’s tail wheels: retraction, extension, steering, oleo, tail door opening and closing, etc. Virtually all the parts needed attention and overhaul to bring them back up to airworthy condition.

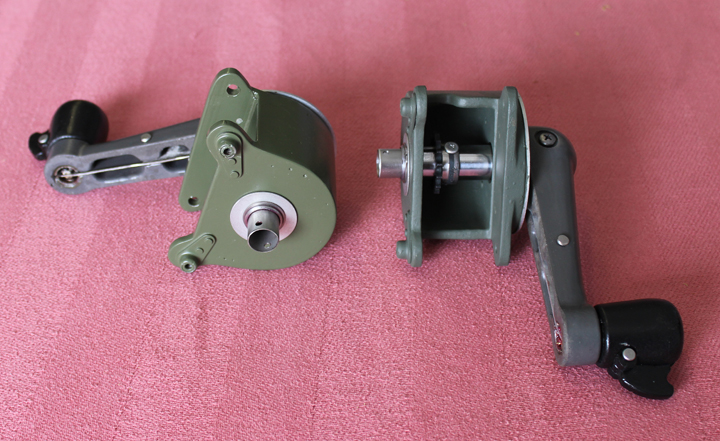

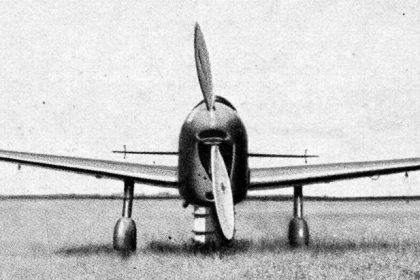

Canopies, Trucks, Opening/Closing Cranks, Windshield Side Glasses: Both canopy hand cranks are finished and installed. Both canopies are ready for installation. All four windshield side glasses are nearing completion. Tom Reilly expects to have them onsite within a week for routing, trimming and final installation. Even though they look similar to the P-51 series, these canopies and windshield glasses are nowhere close in shape or dimension.

Outboard Wings: The work on both outboard wings has slowed as the team is awaiting completion of the last of the aileron and flap hinge points which, following their installation, will allow the close-out of the four bottom rear skins. The remainder of these parts are due within the next two weeks, which should coincide with the team completing the riveting for the tail sections.

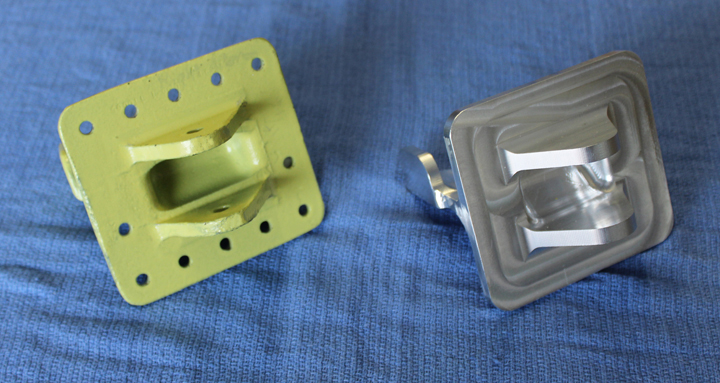

Main Gear Door Opening/Closing Hook Mechanisms: The restoration team has received the final forgings for the main inboard gear doors. These parts hold the multitude of push/pull rods that control the positive lock/unlock hooks, which keep the doors securely closed during flight. They will all undergo installation this coming month.

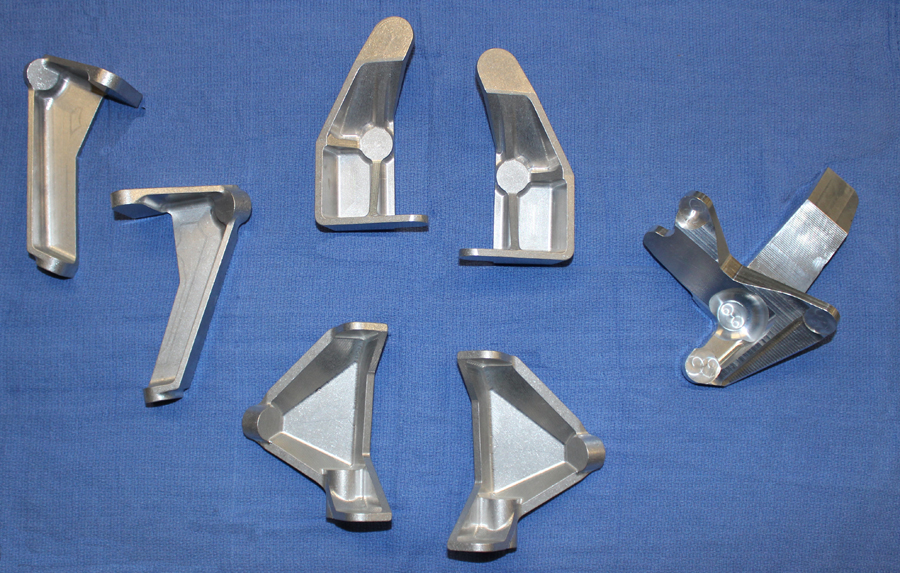

Gun Mounts: The six aluminum gun mounts are now completed and awaiting installation in the center section.

Inboard Flap Hinges: Both center section flap hinges are now aligned and permanently installed.

Coolant Exit Doors, Header Tanks: Casey Hill, English wheel forming wizard, is due in Douglas this week to complete the forming of the two complicated interior coolant exit door skins. Also, both coolant header tanks are now installed, one in each rear fuselage.

And that’s all for this month. Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in early November for the next installation following the XP-82′s road to recovery!

Where will your twin mustang be on display once it is restored? I would enjoy seeing it very much. I love WWII Warbirds!!!

The Twin-Mustang will be airworthy and sold to the best bidder!

Thank you so much for these updates on the incredible work you are all doing on this Twin Mustang. It is pure joy to see such craftsmanship and so good to know that you are, all of you, working on such a rare and beautiful bird with such dedication. Twin Mustangs definitely don’t grow on trees – thanks for taking such good care of her!

Blue Skies and God bless!

LOVE THE PROJECT AND HOPE TO SEE IT AT OSHKOSH.

That’s some proper job you do with that beatiful and rare warbird. With all the parts you have to make, do you upgrade to modern materials, alloys, surface treatment? Do you upgrade parts to solve issues that were present with the way it was solved/built back in the days?

I would like to an XP-82 t-shirt. How can I place an order.

Regards,

Rob