WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. We thought you’d enjoy seeing what they’ve been up to! Click the jump to find out more…

Wings: Sheet Metal

The men have been making excellent progress on both wings. The majority of skinning and riveting for the forward top and bottom of the right-hand wing is now complete. All of the in-conduit wiring, pitot, and aileron cable tubing, and drop tank pressure and feed lines are now pre-installed in the right-hand wing.

The final structure set-up on the left-hand wing is now complete, and the preliminary dimpling, counter-sinking and skinning of the top skins is progressing well. Due to the spring/summer temperature fluctuations, the crew must check the washout, sweep and dihedral each morning when it is cool, and each afternoon as the temperature increases 30 to 40 degrees. The wings are in a jig to help prevent the temperature variations (expansions and contractions) from changing the set-ups as the exact dihedral and washout measurements must be within one-twentieth of one degree to allow the aircraft to fly “hands off”. With the dihedral and washout locked in to the required settings, the team completed the final reaming for the .3735″ lower wing-attach bolt holes on both wings. A reamer is necessary when precision cut holes are required, both in terms of circularity and size, as a normal drill bit will not suffice.

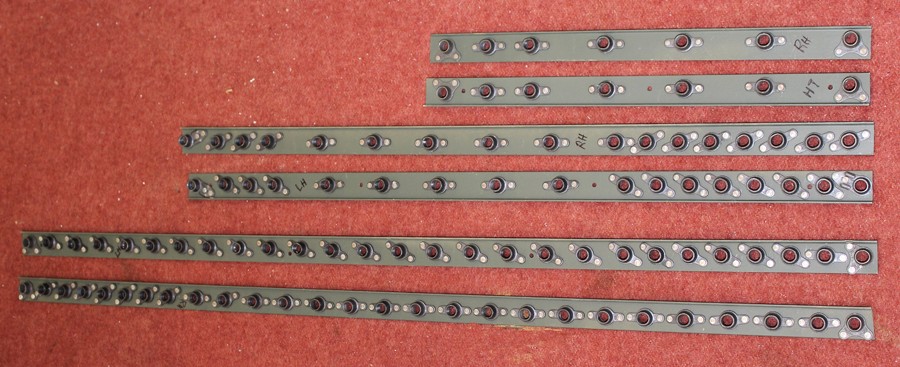

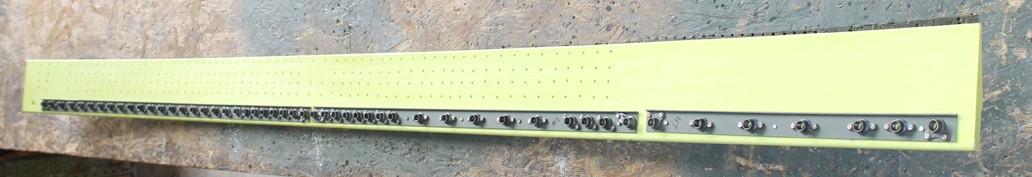

The XP-82’s wing-attach angles require nut plate channels for the bolts to fasten into due to the lack of access for tightening standard nuts. For some reason, North American chose to use nut plate channels with nonstandard spacing on the upper sides of the lower attach angles located in the fuel tank bays. None of the project’s original nut plate channels were repairable, and the non-standard spacing made it impossible to purchase replacements from any supplier as they are no longer manufactured. Therefore the restoration team had to manufacture their own nut plate channel strips.

Also, one of the team’s sub-contract machine shops is now close to completing the aileron sectors and mounting hinge points for both wings.

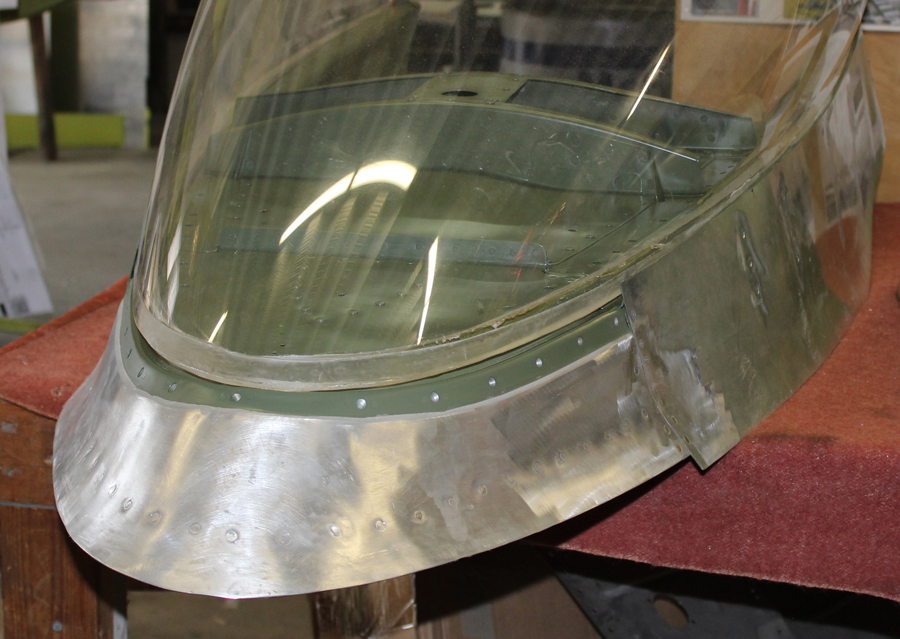

Canopy, Windshields and Glare Shields:

The second canopy glass has now been fitted into the freshly repaired canopy frame. Parts from three damaged canopies in the project were required to repair and complete the right-hand canopy frame.

The right-hand glare shield was another story. The left-hand glare shield was relatively simple restore, as it was basically undamaged. The heavily damaged, right-hand glare shield required a major amount of repair and the splicing together of many re-pressed parts to complete an airworthy unit.

The project has finished manufacturing the two central pieces of 1.5” thick, bullet-resistant windshield glass, and is in the process of forming the four side glass side pieces to fit the windshield bows and glare shield frames.

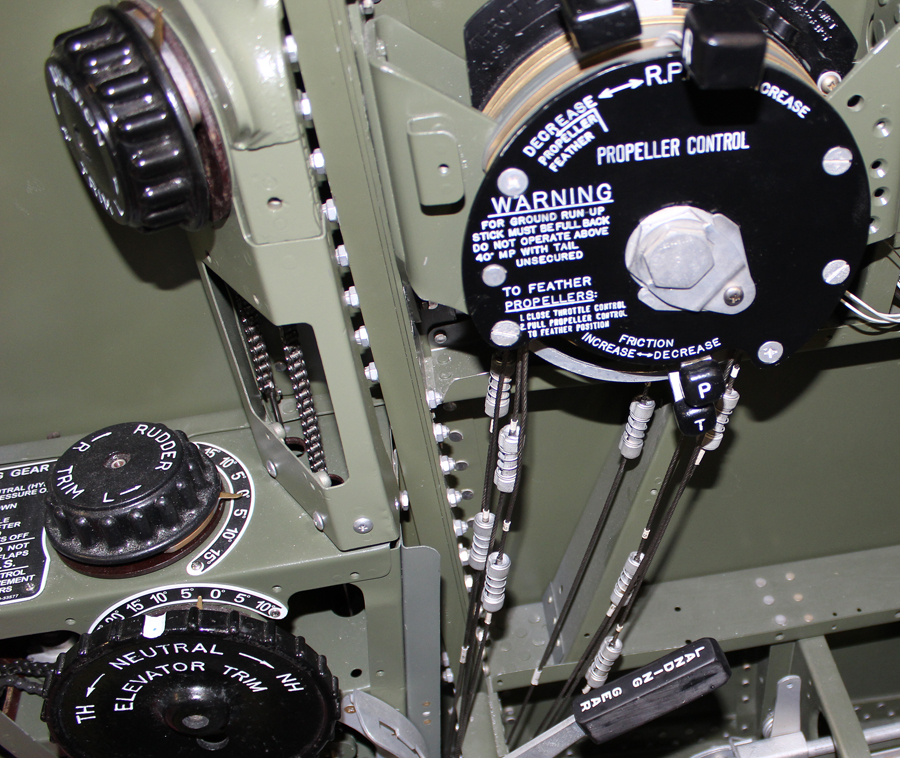

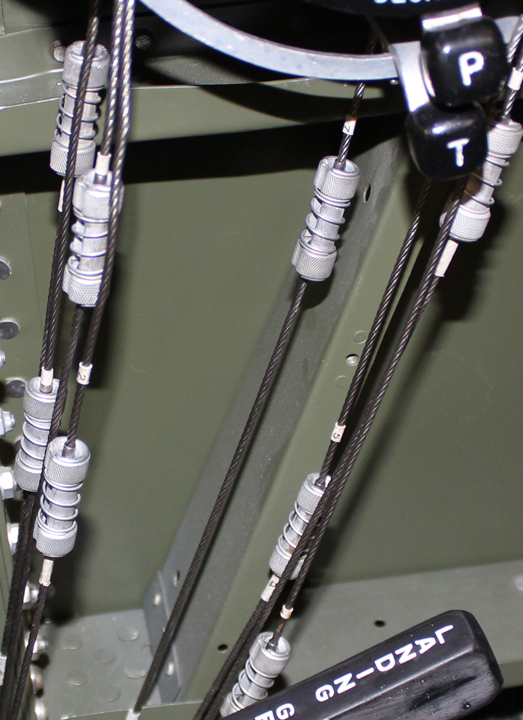

Throttle Quadrant Cables:

One restoration team member is currently completing all of the cable hook-ups that simultaneously link both throttle quadrants together via cables that run through the center section from one cockpit to the other.

Inside Skins for Outboard Gear Doors:

Another workshop has built the tooling for pressing a set of skins for the serpentine-shaped outboard gear doors, and is getting ready to manufacture the parts for the XP-82.

Heat Treating:

The project took another batch of parts that needed heat-treating to Thrush Aircraft in Albany, GA, to be brought up to T-3 condition. Tom Reilly said the amount of special help Thrush has given towards the XP-82 has been priceless, and wishes to express his thanks to the company.

And that’s all for this month. Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in early June for the next installation following the XP-82′s road to recovery!

Thankyou for restoring this old war bird. I live in Al. Do you accept volunteer workers. It would be a privlige to just sweep the flooraround her.

Thanks

David

A worthy project to add to the fleet of War Birds and not one that will go unnoticed. Love War Birds.