by Richard Mallory Allnutt

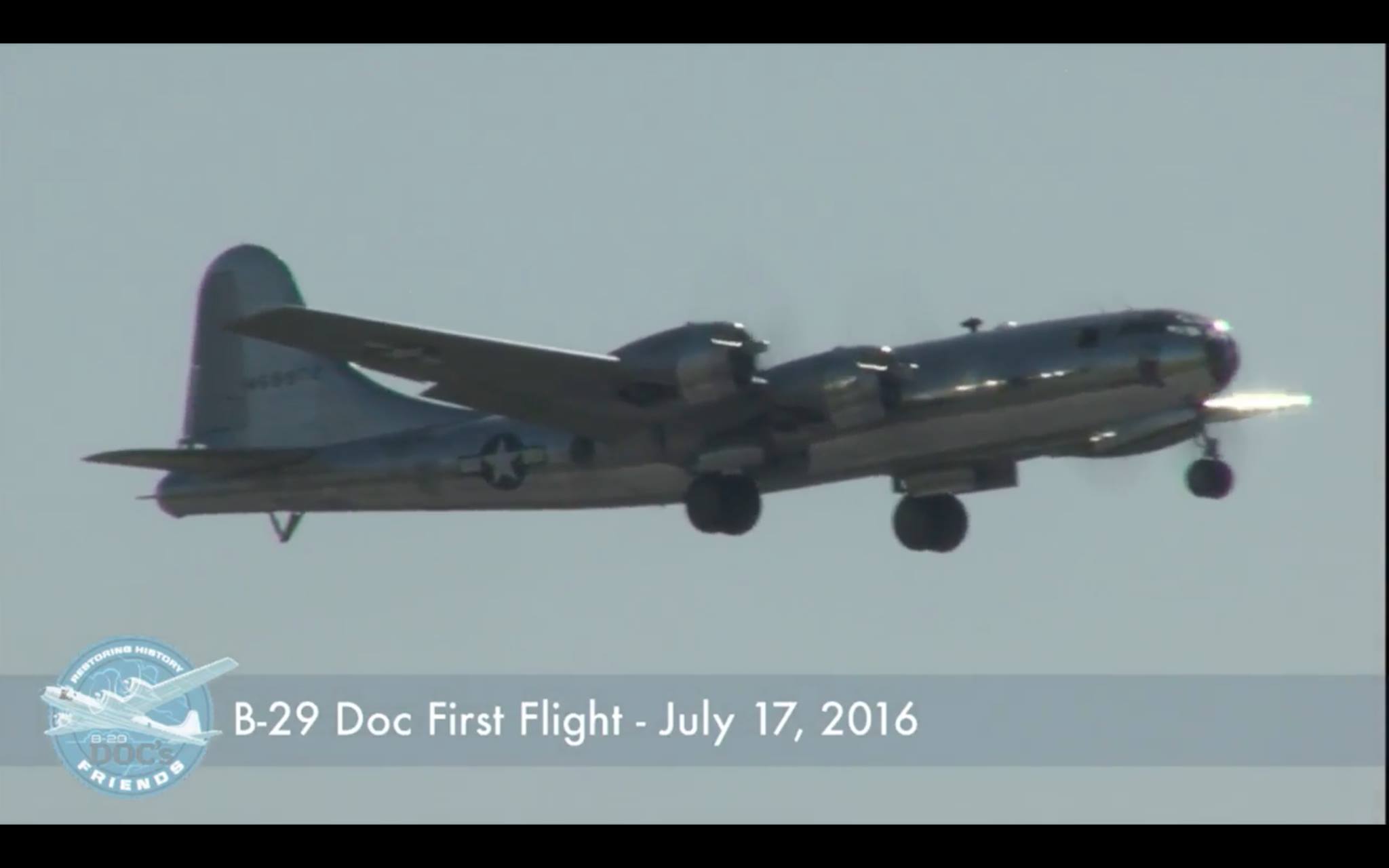

Today we are pleased to report that the B-29 Super Fortress known as ‘Doc’ made her first post-restoration flight in Wichita, Kansas this morning. Following more than two decades of adventure and hard graft since Tony Mazzolini discovered her at the China Lake Proving Grounds in 1987, the world now has two flying B-29’s!

Under the guidance of her crew, the silvery Super Fortress taxied out in the haze and early morning light to the 12,000′ long runway at McConnell Air Force Base. The flight engineer ran her engines up to takeoff power, flexing her muscles to test their strength. Everything seemed to be going according to plan, but during the pre-flight checks, the crew discovered that the bomb bay doors would not seal properly, so they taxied her back to the start point to check on the problem.

The mechanics got to work on solving the issues, and soon it was time to get going again. The crew started the engines, and B-29 slowly moved back down the runway again, taxiing beyond the sight of the crowd, such was the dip in the terrain. Monitoring temperatures and pressures, the engineer finally gave the pilot the go-ahead to begin the takeoff roll. He released the brakes, and slowly the vintage bomber moved forward, gathering speed as she rolled down the expanse of concrete….

She took off smoothly, and made several circuit of the airfield while Doug Rozendaal flew alongside in the chase plane to visually inspect the airframe for any noticeable issues. And then she pointed her nose back to the airfield and landed safely once more. We will be sure to report more details as they arise.

As a side note, the B-29 was one of the first aircraft to rely heavily upon a flight engineer. The engineer controls the throttle and propeller settings during most stages of flight. He monitors the airplane’s health, and also manages the fuel systems. This allows the pilots to focus their attention on flying, as systems adjustment and monitoring is a full time job. Oddly, the flight engineer has his back to the pilots, and can only get occasional glimpses forward from reflections in his instruments.

Typically, the only time the pilot will touch the throttles is while taxiing, and during the initial stage of the take off run. The flight engineer starts the engines and warms them up. He then helps the flying pilot taxi out to the run-up area. The flight engineer will then test the engines at take-off power, check the magnetos and cycle the props through their speed and pitch settings to make sure all is well. The pilot will taxi out to the runway threshold once these checks are complete, and then set the brakes. The flight engineer slowly brings the engines up to 30” manifold pressure. At which point the pilot releases the brakes, and the bomber begins her take-off roll. The pilot is controlling the throttles during this phase, gently increasing power. Once he senses rudder authority (65-70 mph) he calls out, “Engineer’s Throttles. Set Max Power”. Whereupon the flight engineer will gently push the throttles up to take-off power. This used to be 44” manifold pressure with the original -23 engines, but should be 42” with the new “hybrid” engines (identical to FIFI’s). Once aloft, the flight engineer manages the engines and propellers until the aircraft is back on the ground. The pilot will request throttle adjustments by asking for specific manifold pressure settings or pre-determined flight regimes. A typical call would be “Set power Two Three” (ie. 23” manifold pressure). The shorthand helps prevent confusion between the non-flying pilot (who handles the flaps) and the flight engineer.

———————————-

Congratulations to Tony Mazzolini, who began this adventure, to the many volunteers who put their hearts and souls into getting to this point, to all who contributed financially and to Doc’s Friends who made completing the restoration project possible. This is a marvelous day for the vintage aviation community worldwide!

WarbirdsNews also wishes to offer our special thanks to Steve Jantz for his marvelous photographs that we have been able to share in our progress reports over the past couple of years.

Congratulations on a job well done

This is a great accomplishment. Congratulations to all the people that put in the many hours to make this historic event possible, and establishing another round for the preservation of historic, flyable, aircraft!

Wow, what an incredible job by Tony and all. So impressive.

What a beautiful plane.

Nice article, I liked the final side note very much.

I was born in China Lake (Navy pilot father), so getting a kick…

Cheers!

Welcome back Doc! and thank you to all who put their time, heart, and know how into getting him flying again.

Love War Birds…

This is great! Congrats to all who helped this beautiful aircraft grace the sky’s once more!

My father in law flew on a B29 out of Guam a few times during the war. He was really impressed with the plane and said he had never seen anything so big and powerful.

Congratulations on a job WELL DONE….

Good show!

Great job !!!!!! All the hard work and dedication has paid off! Keep her flying!

The B-29 “Doc” looks so bright and polished as if it just came off the assembly line. Thumbs up to everyone involved for a fabulous job bringing this classic plane back to flying status!

I love it that people are bring history back to life. Congratulations to the crew and the many people that have worked so hard to get this great plane back in the air.

will gun turrets be installed some day?

Thank you for restoring this historic warbird!

Any videos you can post of it firing up and flying?

Good news! Been reading about it a while!

Hope it can come to Airventure Oshkosh soon!

Used to manage the China Lake’s Aircraft Survivability’s Range in the 70s & 80s where many of the B-29s were stored after WWII. Congrats on saving one more of these fabulous aircraft.

Congratulations Watched the whole flight!

Having been crew on the B-29 as CFC with 160 hours in training,

in 1945 hard to keep from crying

Thanks so much for writing in and watching Richard… I am glad that you were able to follow the story in real time. It must have been incredibly emotional for you.

I was there watching from outside the Kansas Aviation Museum. The guy next to me had a portable radio monitoring the aircraft and tower. They actually only made one circuit of the pattern and the pilot called in that a monitor showed metal particles in the oil of one engine so they were going to land. I haven’t heard any more about what they found.

Congratulations to all involved. Wonderful to see these aircraft being brought back to life. Would love to see a B36 come back to life, but knoww that is probably not going to be in my time. Again THANNKS.

I spent many hours as navigator in a B-29 out of Barksdale AFB in 1951-53. I had been a navigator on a B-17 during the war, but was recalled to keep the Russians out of the Korean War. I guess we did. It’s thrilling to see one of these birds in the air again, brings back lots of memories.

I have been watching the restoration since the beginning.

What an outstanding job by all involved.

Hope to see FiFi and Dic fly together someday.

I am probably the proudest man today as I follow the progress of Doc as I have since first discovering that an airplane that I once flew as a crew member during 1954-55 and 1956 at Griffiss AFB, Rome, NY. I was left Scanner on our B-29s at Griffiss, Doc being one of such birds. My heart felt thanks to Tony and all the volunteers who made this “Historic Event” Happen.

Congrats.

Clarence “Pat” Daily TSGT. USAF (Ret.)

[email protected]

I am still following “Doc’s” progress very closely. I only hope that I may someday “touch” “Doc” again after all these sixty some odd years. I only wish that the Form 5 back in those days had the “tail numbers” but they did not. Back in the fifties on my personal flight record, Form 5 only lists (Date, type aircraft and number of hours flown). I could have logged several hours flight time on “Doc” or possibly none at all. But a good chance I did log some time on “Doc” because I flew a few thousand hours on our TB-29Js at Griffiss AFB in Rome, NY back in the early fifties.