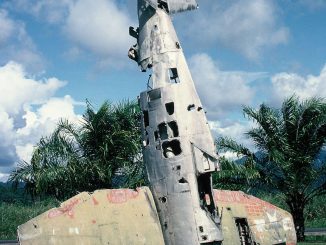

Back in May, 2017, WarbirdsNews shared a report by Chuck Cravens detailing the commencement of a restoration on an ultra-rare Beechcraft AT-10 Wichita WWII advanced, multi-engine trainer. As mentioned in the previous article, the project belongs to the Cadet Air Corps Museum and comprises the remains of several airframes, but will be based upon Wichita 41-27322. The restoration is taking place at the world-renowned AirCorps Aviation in Bemidji, Minnesota, and we now have an update on the progress as it stands so far….

The AT-10 at AirCorps Aviation

by Chuck Cravens

It has been a while since we’ve updated on the AT-10 project. It is such a unique warbird that, upon completion, it will be the only flying example of the type in the world.

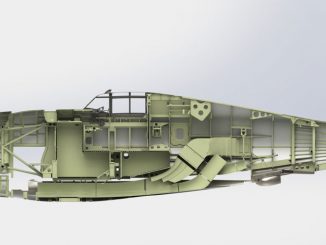

Last time I wrote about the type’s history and showed how the project arrived at AirCorps Aviation. At the time of that report, restoration work was in a very early stage. As is true of most restorations, early work consists mainly of parts fabrication and preparation to begin the actual assembly. Despite many hours of parts production, until that phase ends, there isn’t a great deal of visually clear progress. Parts fabrication will continue, but now there are enough done to begin some assembly work. That generated the visual progress for this update.

Fuselage Formers

Fuselage Forward Structural Framework

The AT-10 is built primarily of wood, but the fuselage from the rear of the cabin forward and the engine nacelles are metal structures. Those assemblies are in the first part of the restoration schedule.

Many thanks to Chuck Cravens and AirCorps Aviation for this article on their AT-10 project. Should anyone wish to contribute to the Cadet Air Corps Museum’s efforts, please contact board members Brooks Hurst at 816 244 6927, email at [email protected] or Todd Graves, [email protected]. Contributions are tax deductible.

Bonus Images…

Related Articles

Texas Flying Legends Museum – P-47D Restoration Update – Feb/Mar…

Texas Flying Legends Museum – P-47D Restoration Update – Jan/Feb…

Texas Flying Legends Museum – P-47D Restoration Update – Nov/Dec…

Texas Flying Legends Museum – P-47D Restoration Update Oct./Nov. 2017

Texas Flying Legends Museum’s P-51C Mustang ‘Lopes Hope 3rd’ Flies!

Texas Flying Legends’ Razorback P-47D – A History

Richard Mallory Allnutt's aviation passion ignited at the 1974 Farnborough Airshow. Raised in 1970s Britain, he was immersed in WWII aviation lore. Moving to Washington DC, he frequented the Smithsonian’s National Air & Space Museum, meeting aviation legends.

After grad school, Richard worked for Lockheed-Martin but stayed devoted to aviation, volunteering at museums and honing his photography skills. In 2013, he became the founding editor of Warbirds News, now Vintage Aviation News. With around 800 articles written, he focuses on supporting grassroots aviation groups.

Richard values the connections made in the aviation community and is proud to help grow Vintage Aviation News.

Be the first to comment

Graphic Design, Branding and Aviation Art