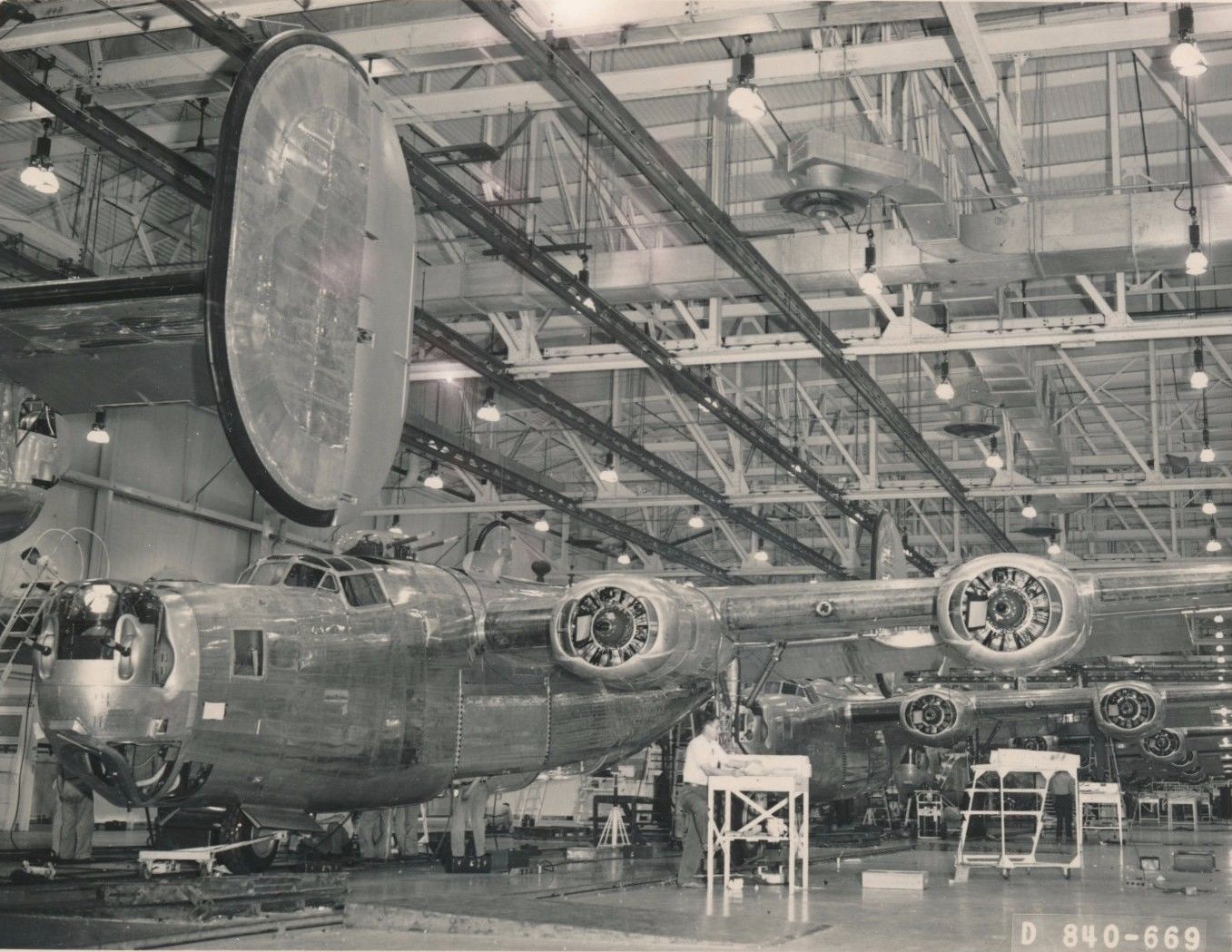

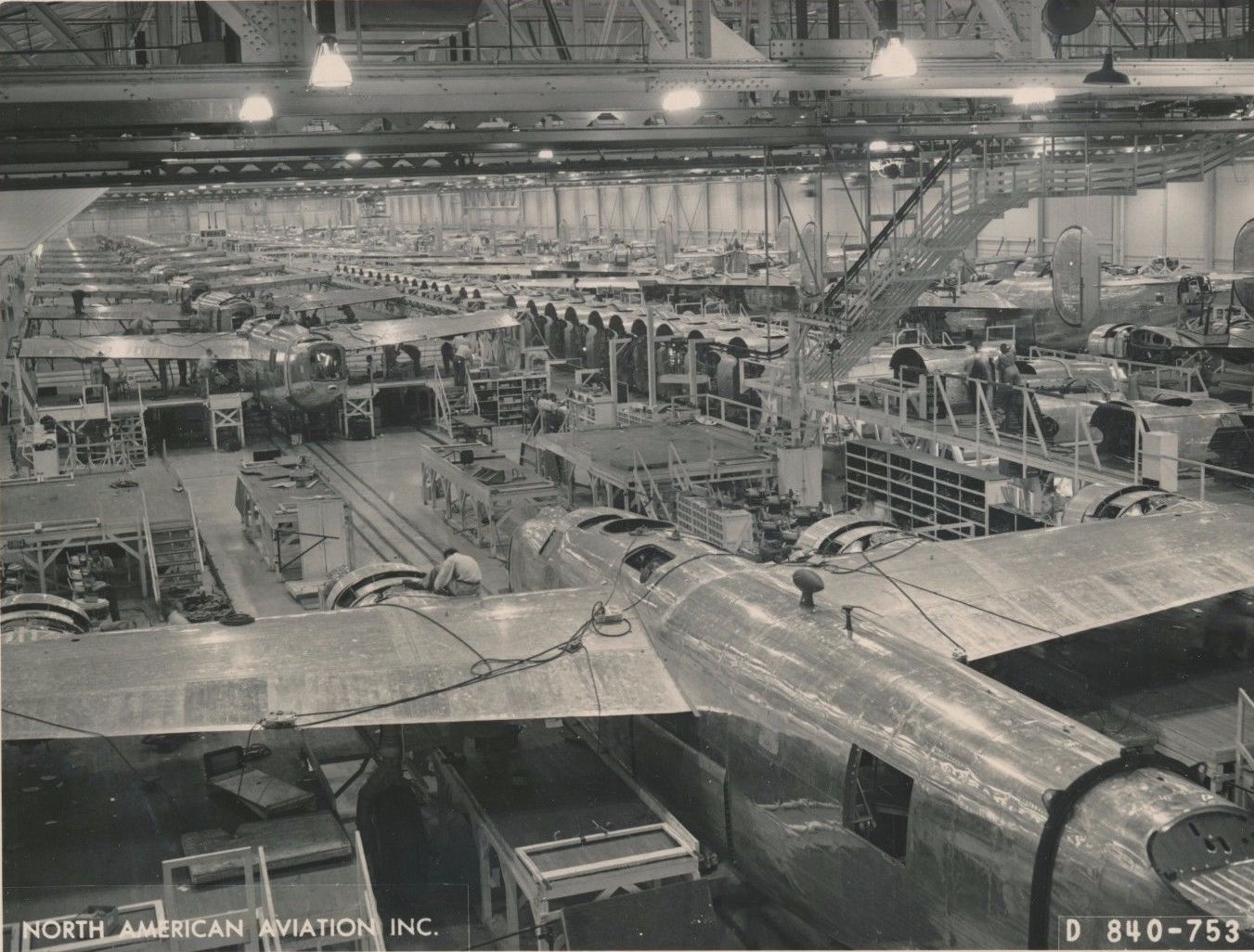

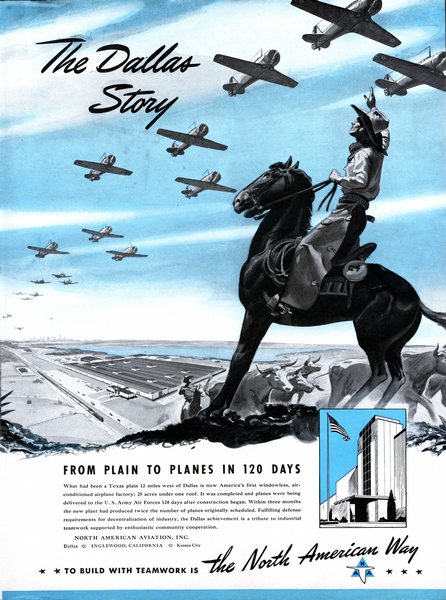

This Thursday evening at 7pm CST Keegan Chetwynd, the Commemorative Air Force museum curator, will present, via webinar, research he’s conducted concerning the history of the North American Aviation plant in Dallas, Texas. This plant was the most productive aircraft factory in the entire United States during WWII; making three of America’s most important aircraft – the T-6, P-51 and B-24. More than 18,000 aircraft rolled of its production lines between 1942 and 1945; in excess of the entire aircraft output from the whole of Italy. At peak production, airplanes emerged from the factory at the rate of more than one per hour. This story is one of the most compelling aspects to having the CAF National Airbase in Dallas, and the CAF headquarters staff want their extended team to understand its importance. In this webinar, Keegan Chetwynd will tell the forgotten story of North American Aviation in Dallas, and its pivotal role in winning the war on the home front.

The presentation will last about 45 minutes and will be recorded for future viewing, but please attend the live presentation if possible (you will be able to ask questions).

Click HERE to listen the recorded version of the presentation

RECALL AT- 6 AIR CRAFT OVER LUKE FIELD GLENDALE ARIZONA DURING WW 2. THEY ARE STILL ONE OF MY FAVORITE PLANES

My father, Richard Thomas Whittle, tried to enlist during WWII, but was rejected because of his age and because he had a family to support. Instead, he closed his profitable psychological testing practice in Dallas and went to work for North American Aviation as a non-union machinist. As a boy, I heard stories about the union foremen threatening discipline “because you are making too many parts on your shift. Each machinist is required to make only so many parts. You are making the others look bad”. Dad reminded him that the country was at war and we needed as many aircraft as we could possibly produce. He said he would continue to make as many parts on his shift as he possibly could. For years, I proudly wore on my finger a simple little stainless steel ring he had made for me at the North American plant in Dallas. Today, at age 77, when I see a P-51, B-24 or AT-6 I wonder if it could contain a part my Dad made so long ago. He has long since passed away, but I hope that at least some of those parts are still flying today.

My dad also worked at NAA from before Pearl Harbor until The plant closed down. He worked primarily on the P-51. I was a toddler at the time and have a few memories. I recall going with Mom & and my younger brother to pick him after a shift until he got 1930 Model A. I remember “air shows” on Sundays, although I can’t be sure if this was every Sunday for on certain ones. Dad was proud to have worked there and especially on the Mustang. Dad immediately began farming in Callahan County.

My father worked at the Dallas plant during WWII. He already had three kids and one on the way when the war started so he left his job in Lubbock and came to Dallas to help with the war effort. He had fond memories of the work they did there. He started as a riveter, went to night school and learned enough math to get him self promoted to the lofting department.

He lost his job at North American the day the bomb was dropped on Nagasaki.

My father N.L. (Norman Leslie) Pete Clark and mother Grace Clark both worked at NAA Dallas during the war years. I don’t know much about that time except Dad always said that he worked on the “Big Birds”. They were both from Oklahoma, just north of the Red River in Bryan County and returned there to live after their work efforts. I don’t have any employee info on either of them. Wish I did! I enjoyed your presentation very much.

My father Rudolph F Sauseda was a riveter and he had pictures standing in front of the Mustangs.The pictures have been lost and I want to know if any can be found. Where can I go to view a museum of these aircraft, also historical info.

Will appreciate any help on this.

I knew that both my maternal grandmother, Grace T. Bowen, and paternal grandfather, C.R. “Charlie” Mondy, Sr., worked at North American during WWII. Granny always said she was a “Rosie the Riveter”. Are there records anywhere which would state on which aircrafts they worked on?

I worked at the facility from 1985 thru 2000. Seems so strange to see it as, more or less, an abandoned factory now. I read that Triumph (current owners of Vought) sold the high speed wind tunnel to Lockheed in 2015. I inferred from that article that the HSWT was built in 1958, presumably by Vought (or LTV). There was also a low speed wind tunnel on the site which was torn down in the early 2000s. Wondering when it was built and by who. Regardless, I had always wondered about the history of the site in general and had every intention of trying to learn more someday and greatly appreciate your efforts and sharing them.

My father, Frank Varney, was was an electrical engineer. He graduated from Cal Berkeley with a BSEE at age 19 and had already begun working for North American Aviation in Los Angeles, CA. At age 22 he was called to transfer as Division Electrical Engineer responsible for all electrical engineering for their new division in Dallas, TX in June 1942- September 1945. He started out working on P-51 Mustangs, and retired at age 65 after being Project Electrical Engineer for the B-1. Other planes he engineered on included the YF-71, XB-70A, X-15, XSN2J-1, P-82, F-86A, F-86D, F-86K, F-93, F-100, F-107, F-108, B-24E, C-82F, AT-6, and SNJ-1 Trainer Series. He was also Program Manager over the Minuteman Missile Cables, and has a cable patent.

My mother wired B-24 bombers at North American during WWII. She was born and raised in Texas and was very proud of her time at North American. She even frequently saw the Shaw of Iran during this period. His father had sent him over to sharpen his skills as a pilot. My mother said he spent more time walking up and down the assembly line looking at all of the girls!

Too bad no one has answered any of the questions asked in the comments! My father worked there as well and I have a pic of him standing beside a P-51. He later was a counter-intelligence agent with the army and was in Japan after the bombs were dropped. Wish I had asked him more questions when he was alive, but I was too young to have any interest at the time

I am sorry Cindy, we do get quite a lot of comments and sometime some fall through the cracks. Do you have any specific question?