by Cosmo Gillespie

On July 25th, 1939, an odd-looking aircraft took off on its maiden flight from Manchester Ringway aerodrome, England, with Avro Chief Test Pilot Sam Brown at the controls. It sported three fins, of which only two had rudders, an unusually bulging fuselage, and two wing-mounted X-configuration Rolls-Royce engines, known as Vultures. Only sixteen months later, it would enter service with the Royal Air Force as the Avro Manchester, and be a vast improvement compared to other aircraft in the heavy bomber class at that time; yet now, it rarely garners more than a passing mention in the history books. For such an outwardly revolutionary aircraft, why so? Perhaps as, apart from its eventual reputation of having many faults and few merits, it was overshadowed by its immediate successor, for which it provided the baseline: the most successful British bomber of World War II, the Avro Lancaster.

The Manchester was not an auspicious starting place for what would eventually become one of the defining icons of World War II. On paper, the Manchester was highly promising, having a larger bomb load, stronger airframe, and greater range than types already in service. However, the aircraft suffered many problems, the majority of which started and finished with the Rolls-Royce Vulture engines.

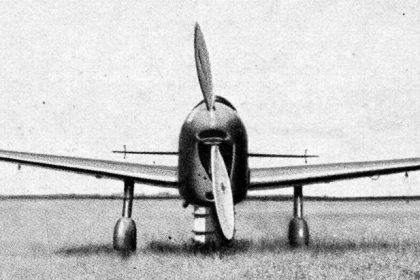

Mounted close to the root of the wing, bulging with twenty-four cylinders, and arranged in an ‘X’ configuration—the only such aviation powerplant to reach large-scale production—it was plagued with problems from its very inception. Prototype builds revealed lubrication issues, connecting rod faults, and that the design of the crank case being cast in two halves was a not unlikely point of failure. This would later prove true, and be joined by a host of other issues.

The poor lubrication was not solved in the production models of the Vulture, and was a common cause of seizures and fires. Problems with the material of the main crankshaft bearings meant they often failed. As suspected, misalignment of the crank-case halves could cause overheating and subsequent fires. Bolts securing connecting rod end caps were prone to random failure, the source of which was untraceable, and invariably, this would lead to a catastrophic and immediate engine failure.

This high rate of failures brought to light the next stage of problems: the Manchester’s single engine performance, so vital for a multi-engine aircraft, was abysmal. One source quotes it as having a 75-percent chance of crashing after the loss of an engine before an emergency landing could be effected. It was not unknown, either, for the remaining engine, when more power was demanded from it to try to keep the aircraft in the air, to become overheated and catch fire itself. At this point, an aircraft’s fate was sealed; the gliding capabilities were practically nil. It is telling that first-hand accounts of flying from Manchester aircrews are practically non-existent.

The Vultures that did bring their aircraft back were not popular with the ground crews. The X-configuration meant that changing spark plugs necessitated all four cowlings being taken off, and that itself required the intake and exhaust manifolds to be completely removed. Problems with coil ignition units led to a need for a fleet-wide retrofit of magnetos. All Manchesters were grounded several times for such issues, a contributing factor to their short period of operational service. Having first been delivered to squadrons in November 1940, production was stopped in the same month next year, and a gradual phase out of Manchesters was started, bringing an end to the brief, bleak career of what should have been a technically groundbreaking aircraft.

Through all of this, the designers at Avro had been hard at work, using the Manchester as their baseline in the interest of economy. Employing Manchester components wherever possible meant less wasted materials, a ready-made wealth of spare parts, and fewer changes to be made in factories, so therefore a quicker entry to production.

Among the many changes made, the central rudderless fin was deleted, the wingspan widened by twelve feet, and the height increased by an inch. The design that rolled off the production line could go higher, faster, and further than its predecessor, carrying thirty percent more bombs and with twice as many engines, and truly reliable ones at that- as the Battle of Britain raged, production of the Rolls-Royce Merlin had been stepped up, and the decision was made that this should be the powerplant for the new bomber. Being a whole different beast, the design deserved its own name, and was re-christened immediately following the first flight of the ‘Manchester III’ on January 9th 1941, again with Sam Brown as pilot. As she roared back to earth and her wheels squealed on the runway of now RAF Ringway, the ‘Lancaster’ had made her first landing.

At the end of that year, Christmas came early for the pilots of No. 44 (Rhodesia) Squadron. On December 24th 1941, they were the first operational squadron to receive the Mk 1 Lancaster, though the aircraft would not see service until the new year. The first operational mission was flown on March 3rd 1942, when four of the squadron’s Lancasters left RAF Waddington to lay mines in the Heligoland Bight and were entirely successful, with all aircraft returning safely to base.

The Lancaster’s successes were to continue, with it eventually becoming not only the most famous British bomber of World War II, but arguably the most successful. Through many role conversions and suites of extensive modifications, the Lancaster became much more versatile within the heavy bomber role, as well as finding uses in search and rescue, maritime reconnaissance, and even for photo reconnaissance missions.

They were known as a joy to fly, once taken firmly in hand, and with a confident pilot at the controls, could be coaxed into performing “almost as well” as a Spitfire—the words of Alex Henshaw, when he was Chief Test Pilot of the Castle Bromwich shadow factory near Birmingham. When they started producing Lancasters, Henshaw performed the post-production test-flight for many of them, and treated them much like the Spitfires that he was more accustomed to. Gliding turns, spot landings, side slips, and even full barrel rolls were not outside the realm of possibility. With radio landing aids, a test-flight could be conducted entirely in cloud with utmost confidence. A particular feat, and something Henshaw demonstrated several times to visiting dignitaries, was flight with two engines cut on the same wing, and doing maneuvers with the working engines on the top of the turns. Wing Commander Guy Gibson VC, DSO & Bar, DFC & Bar, had it demonstrated to him that the Lancaster was able to fly on just one working engine, gradually losing height but still quite maneuverable. This, in particular, was a stark comparison to the Manchester’s abysmal performance after engine loss.

Guy Gibson’s involvement with Lancasters was to fly them in perhaps their most famous episode: the Operation Chastise raid on the Ruhr Valley dams, for which yet another variant was designed to hold Barnes Wallis’ bouncing bomb. Variants were also modified to take ‘Tall Boy’ and ‘Grand Slam’ earthquake bombs. Overall, the statistic that most starkly shows the improvement from Manchester to Lancaster is the accident rate: whilst almost one in five Manchester-produced aircraft was destined to crash as a result of engine issues, Lancasters had the lowest accident rate of all the Allied bombers. So, from an inauspicious start in a failure-ridden mess grew a reliable icon which practically defines the RAF bombing campaign against the European Fortress, and certainly made a significant contribution to the eventual Allied victory.

Great article and quite an education..