A lot has happened at GossHawk Unlimited in Casa Grande, Arizona since we last spoke with them about the Consolidated PB4Y-2 Privateer in their care. They have been hard at work on Dan Kirkland’s Flugwerk FW-190A8/N project, and we are happy to say that she has just made her first test flight! WarbirdsNews has been in conversation with Gosshawk Unlimited’s Lindsey Goss for the past several weeks on the project, and she has filled us in on what this effort has involved.

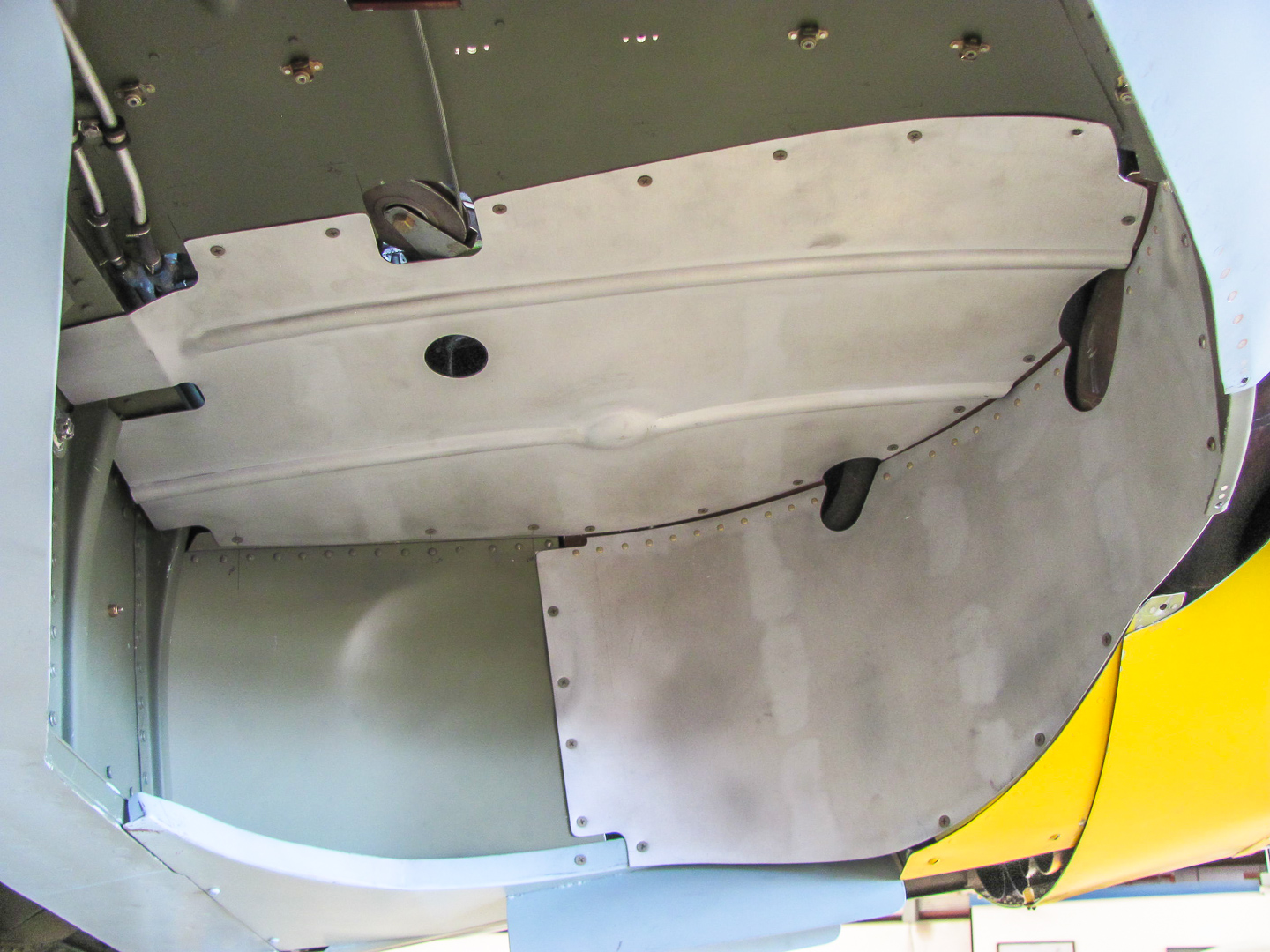

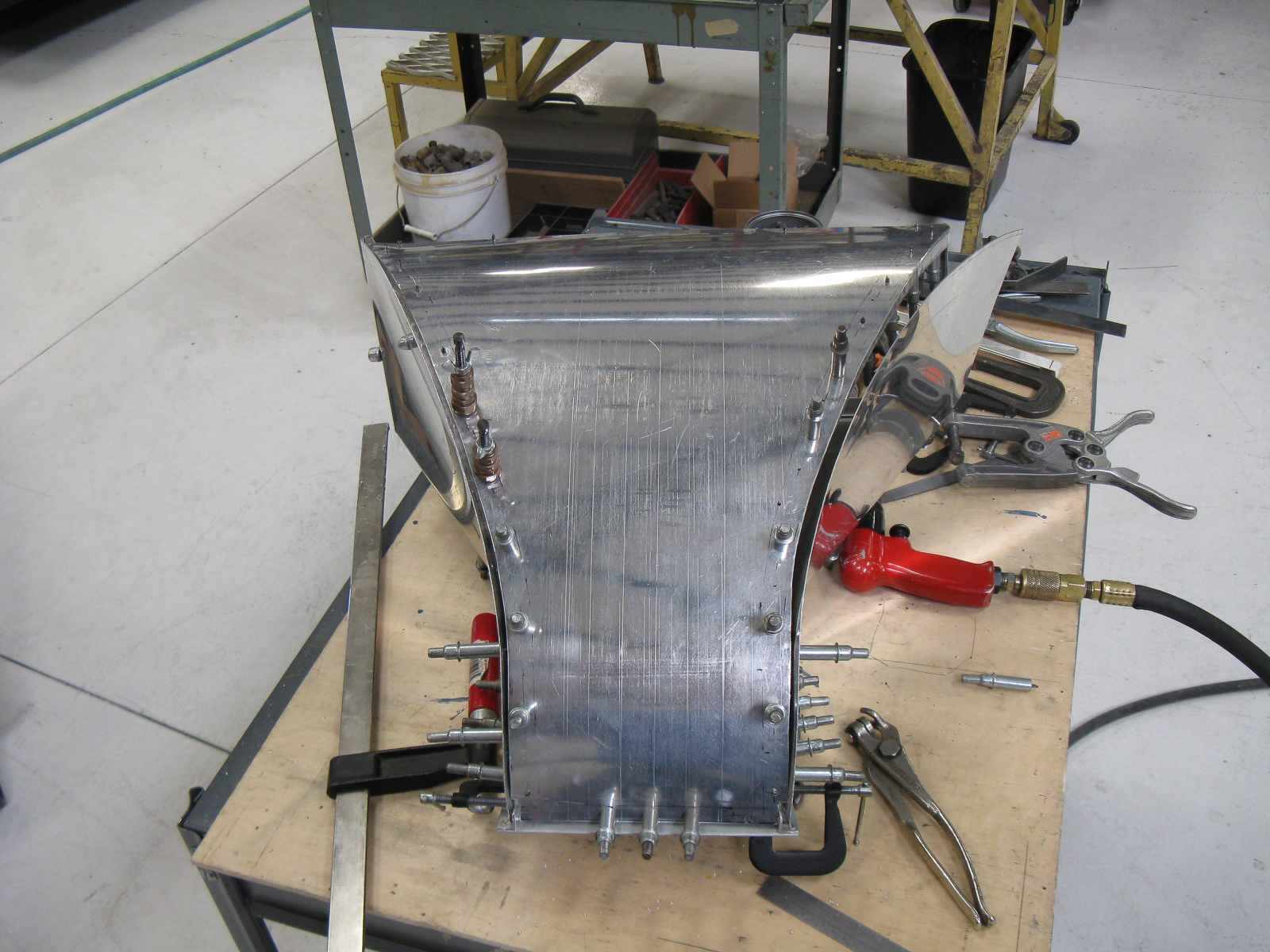

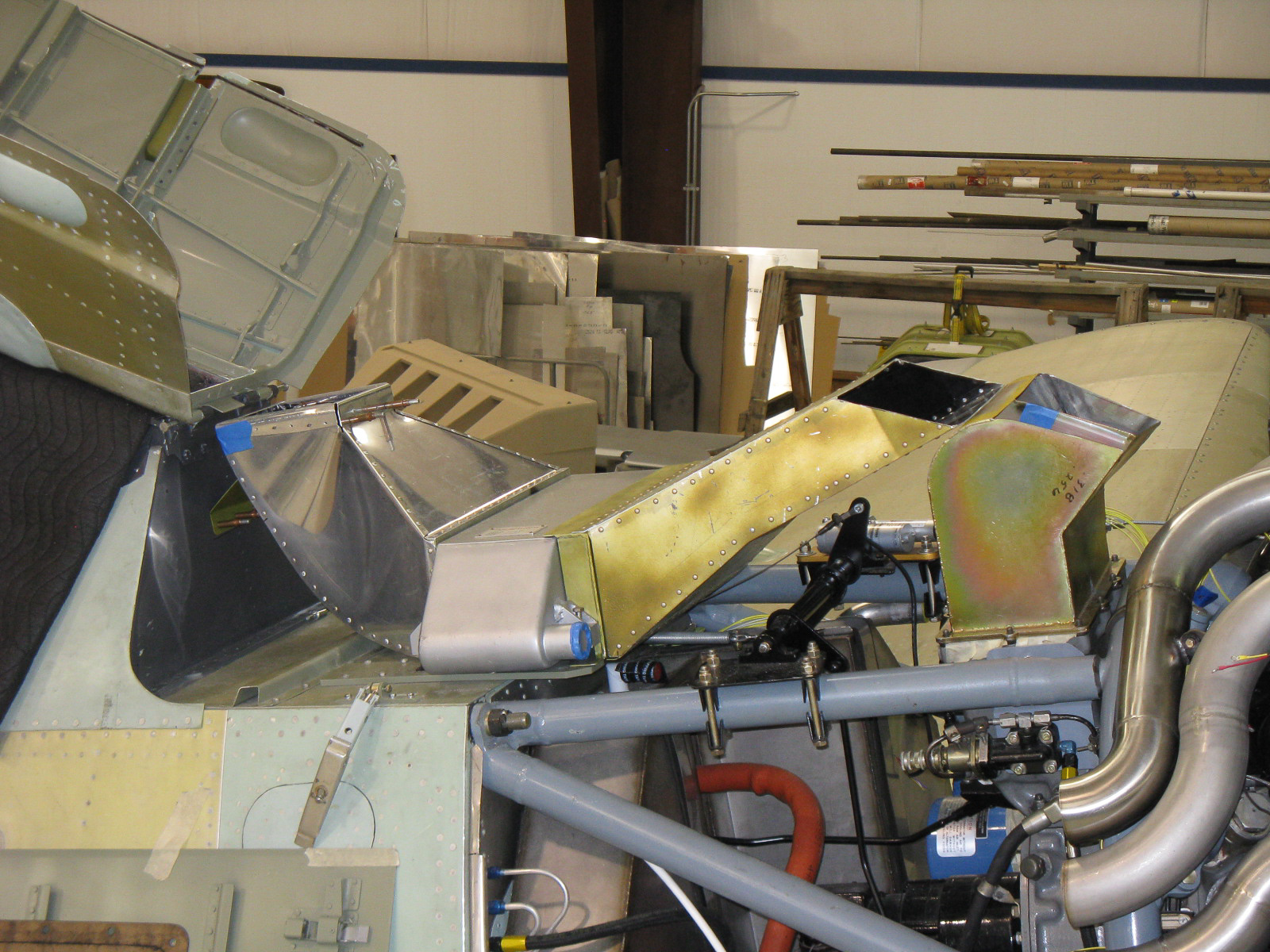

The Flugwerk FW-190 is essentially a high-end kit-plane, requiring a sophisticated approach to assembly, and a good deal of customization. A lot of GossHawk’s energy has gone into reworking the parts so that they fit properly. Much of this effort has focused on the wing leading edges, which required a complete rebuild. Custom fillets for the wing-joins also needed manufacturing on site as well, as the parts supplied with the kit did not fit what GossHawk had already built. GossHawk engineers also had to trim the wheel wells so that the landing gear would fit properly too, and fabricate entirely new gear doors.

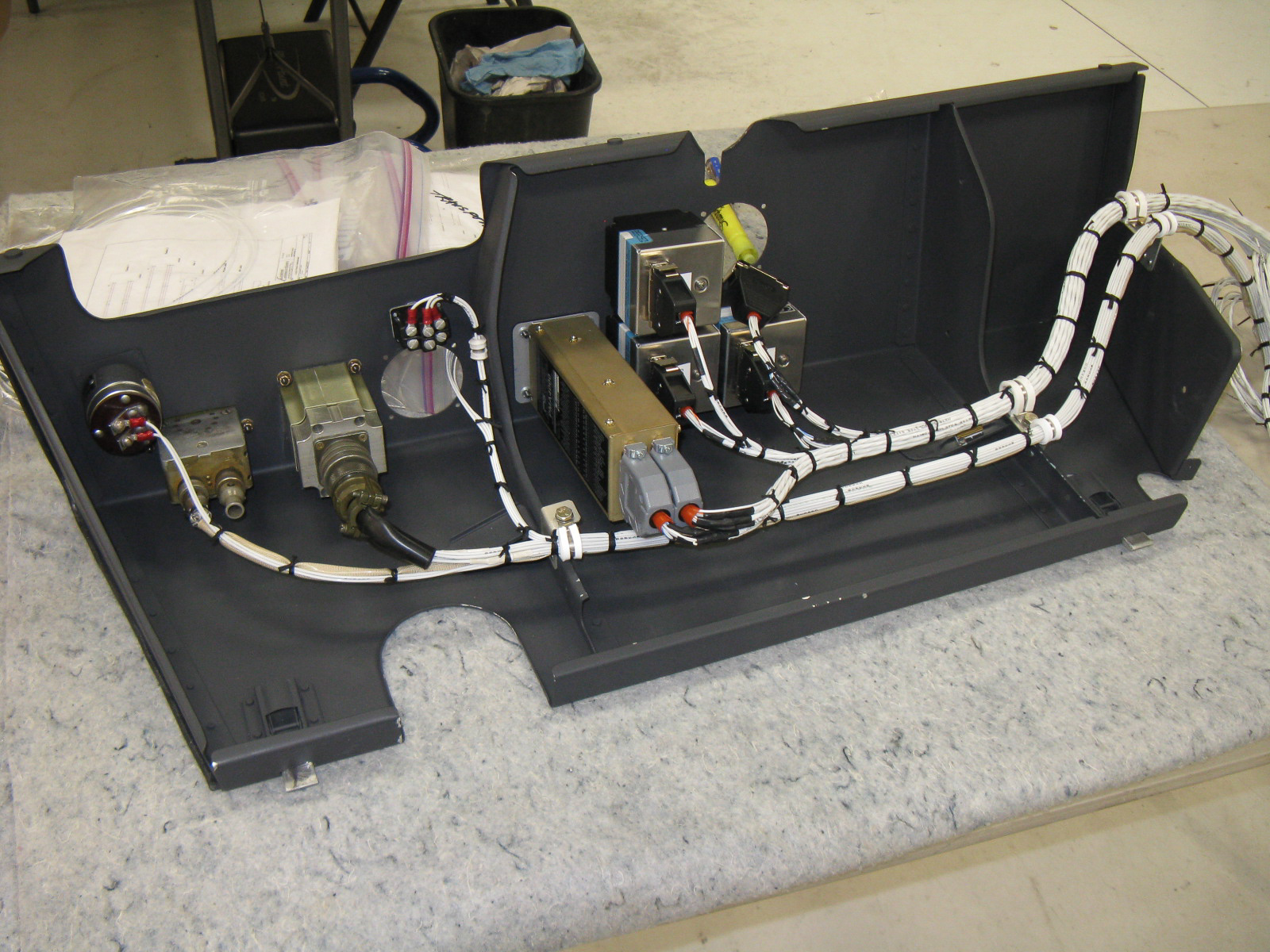

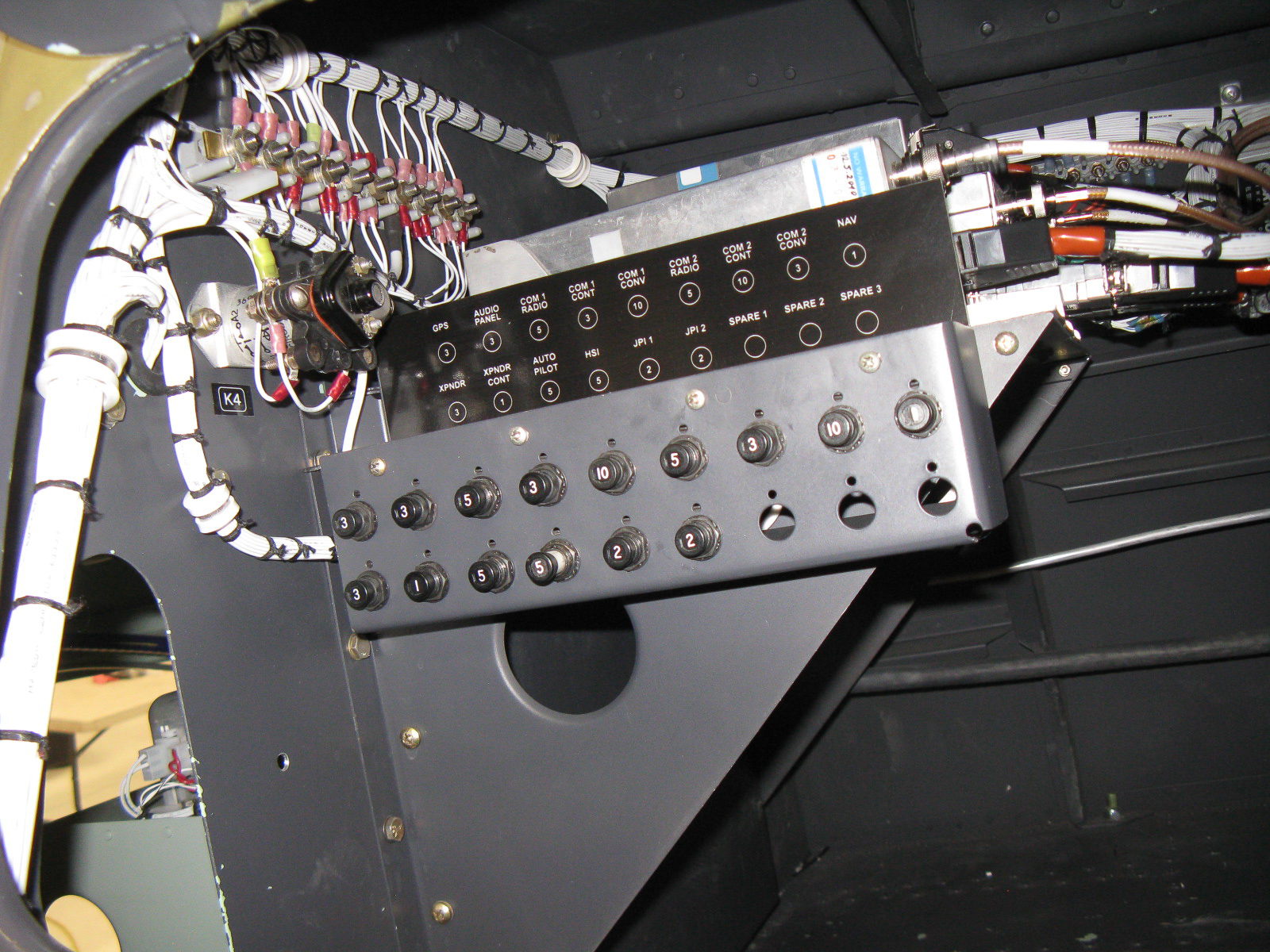

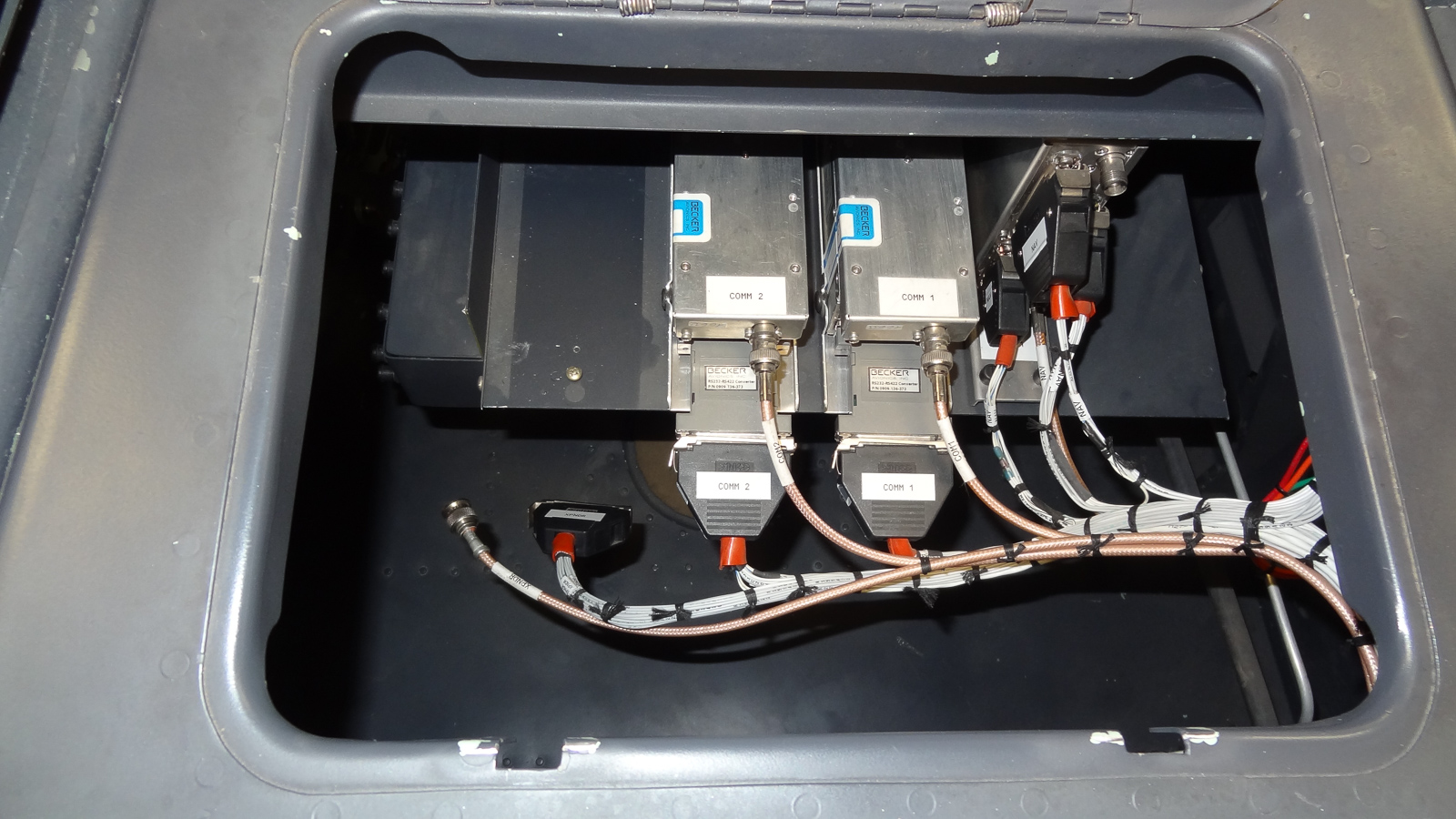

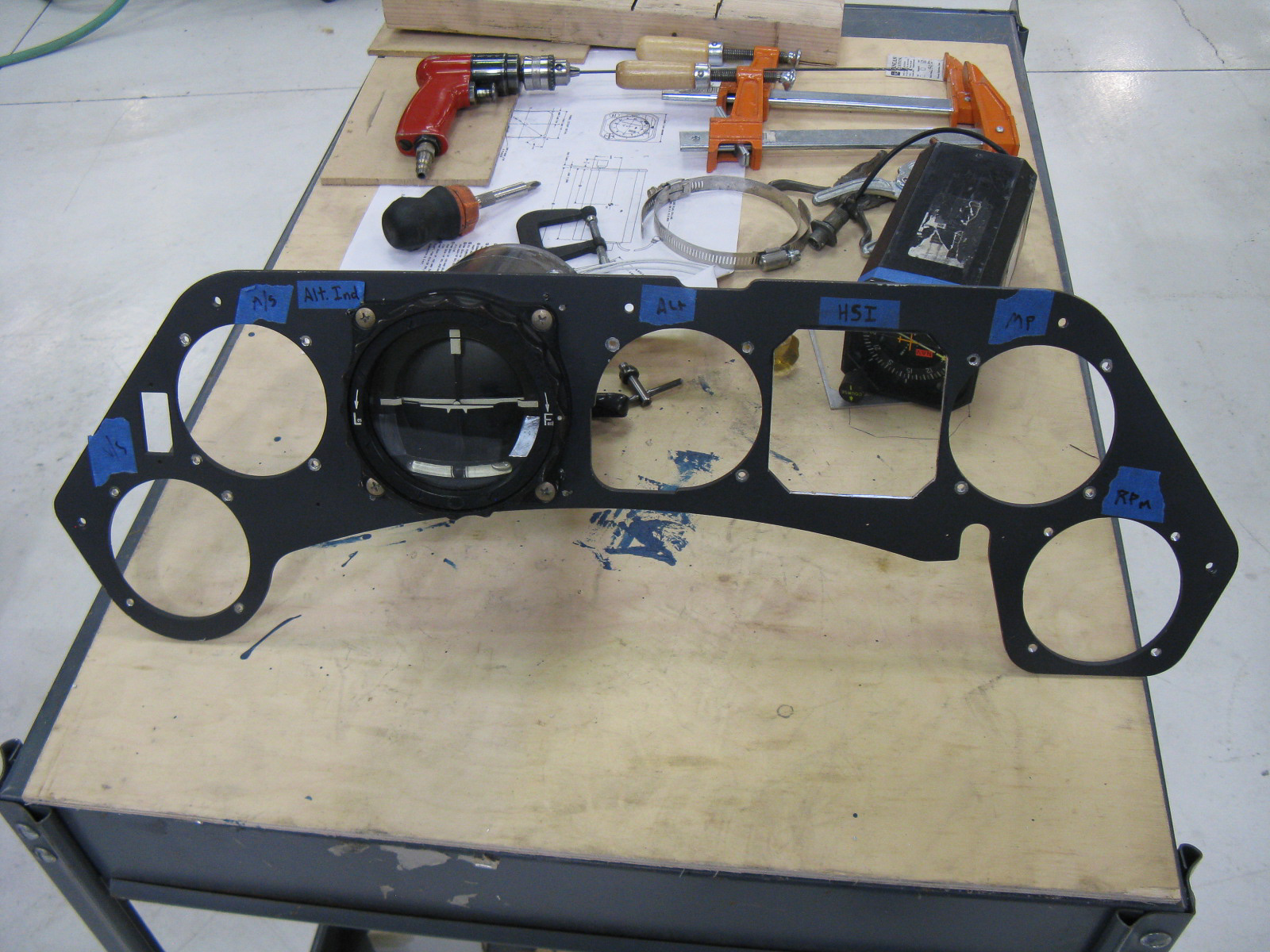

GossHawk contracted Custom Connections to completely wire the aircraft, not an inconsiderable feat given the aircraft’s complexity. GossHawk also built a brand new instrument panel and side control consoles.

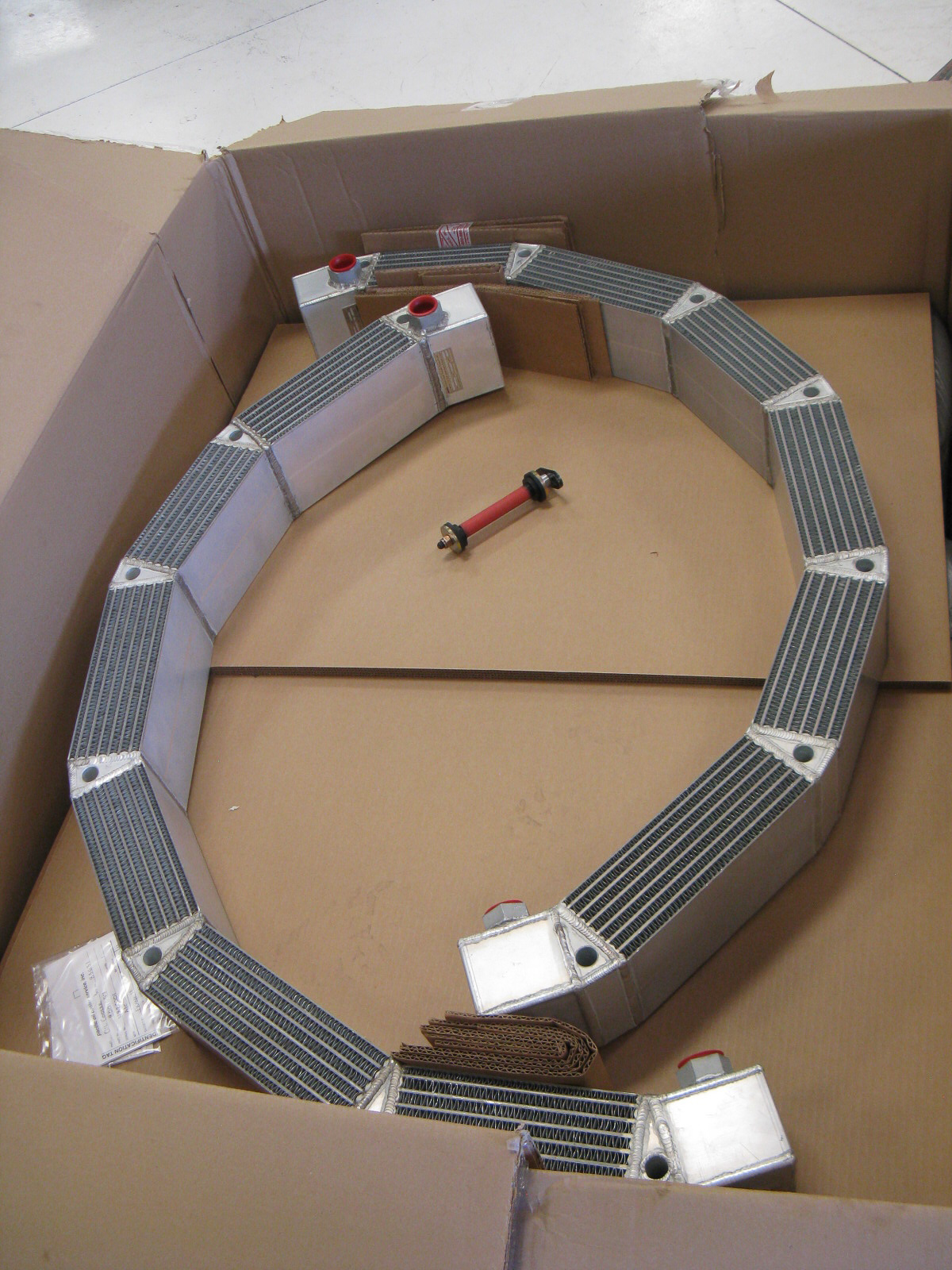

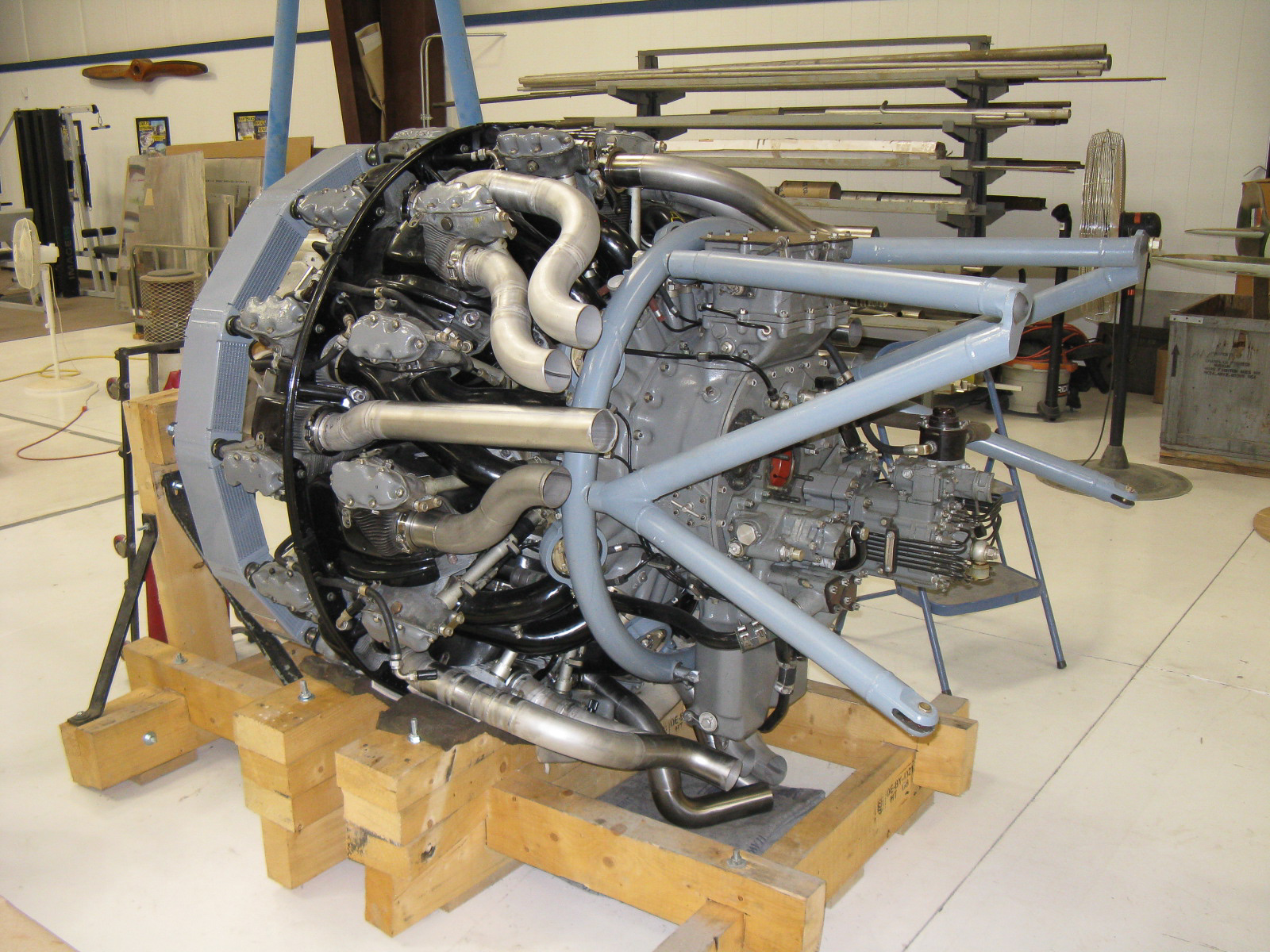

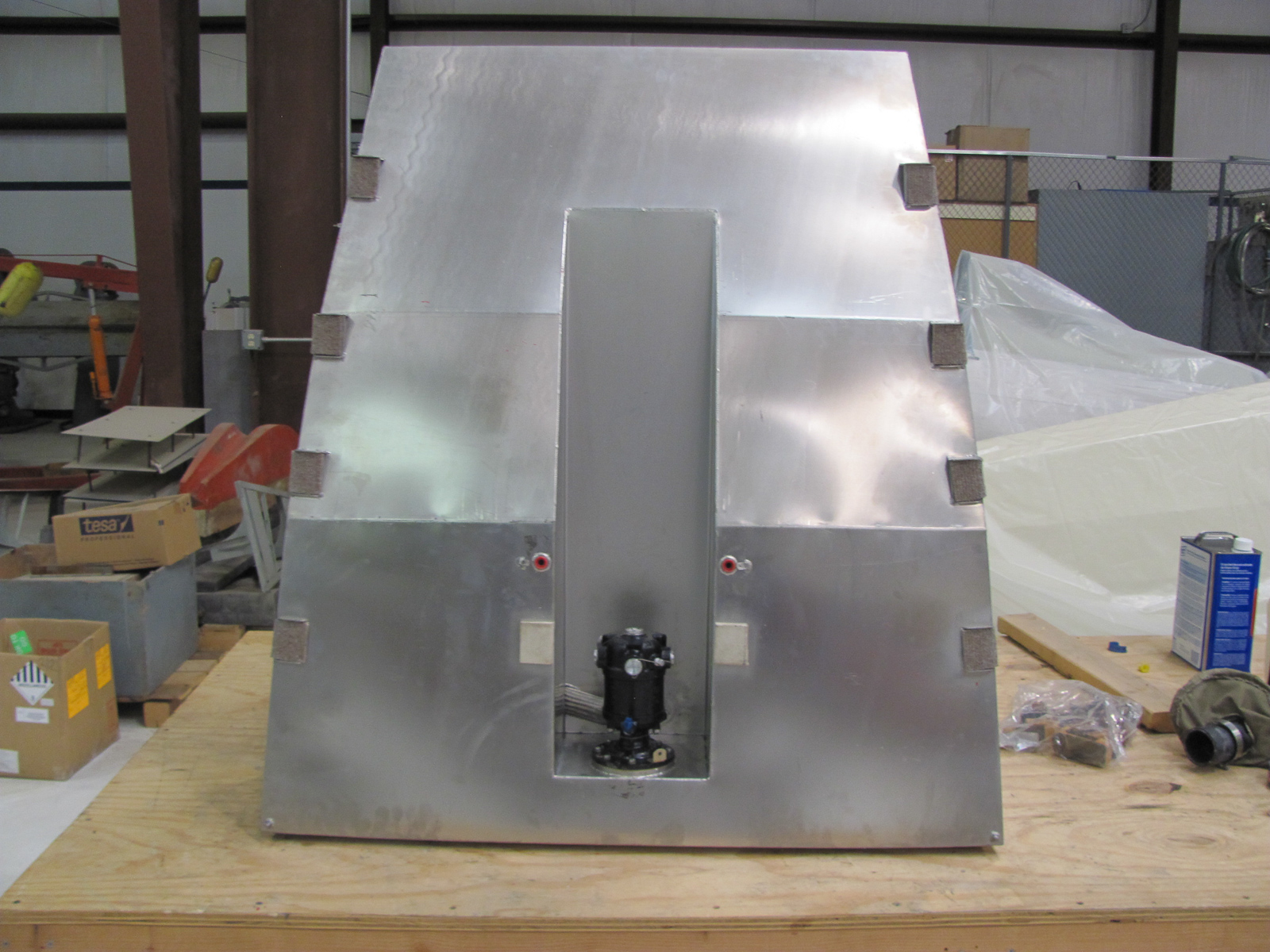

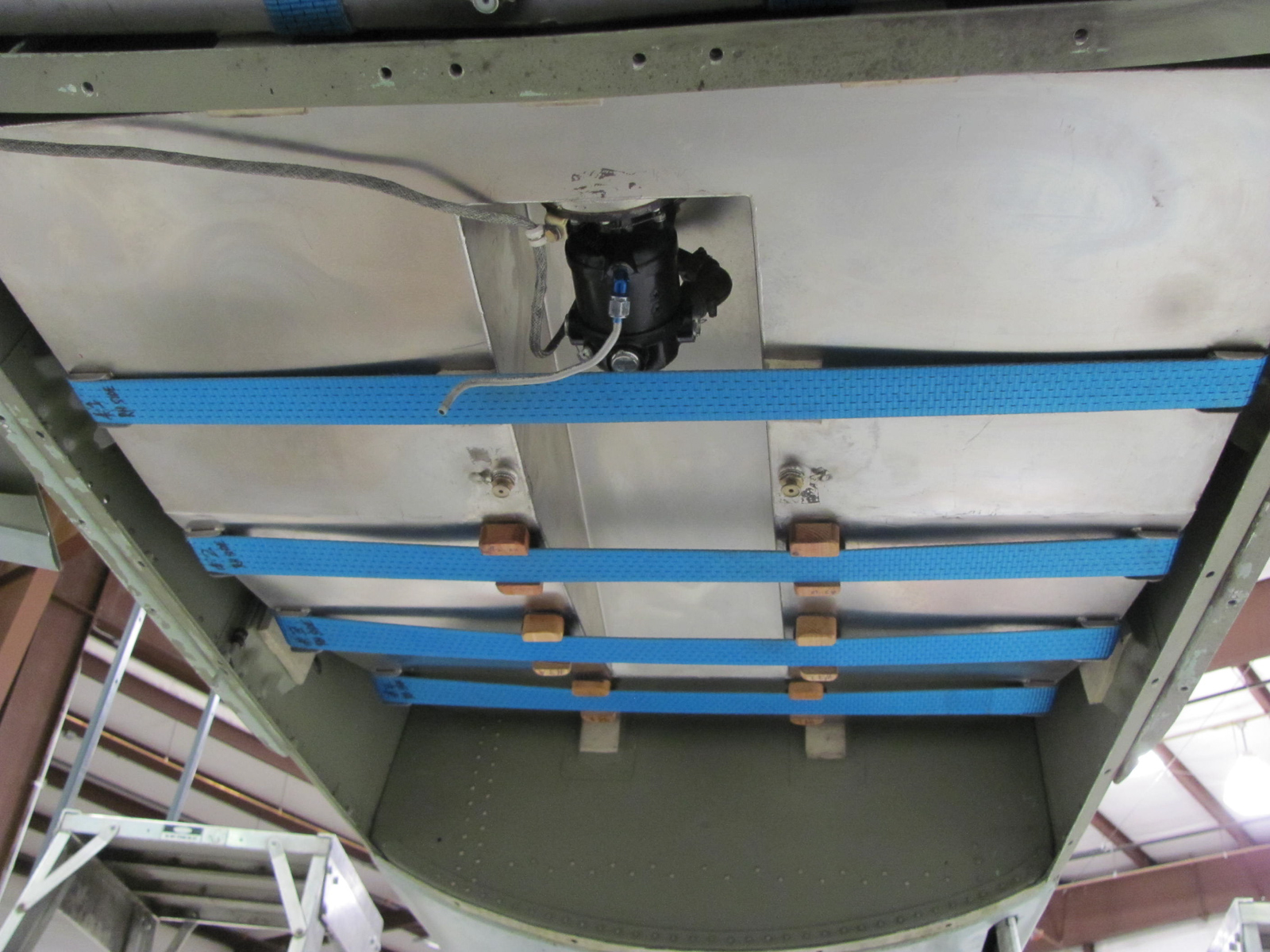

Given the prior experiences of other groups working on Flugwerk FW-190s, a lot of thought has also gone into the cooling issues that these aircraft suffered from, just like the original Focke-Wulf Fw-190s did in the early stages of their development in WWII. In addition to the Flugwerk-supplied oil cooler which sits in the forward fuselage compartment where the machine guns would normally be installed on a real Fw-190, GossHawk Unlimited fitted an annular oil cooler, custom-designed by Pacific Oil Cooler, in front of the engine just behind the nose cowling. This project had a Russian-designed ASh-82 engine as its powerplant, like most of the Flugwerk FW-190s, and the beefed-up oil cooling system has performed well throughout the engine runs and taxi trials that GossHawk has performed over the past few weeks.

THE TEST FLIGHTS

Klaus Plasa has been performing the test flights. Plasa, a pilot in the modern Luftwaffe and a graduate of the National Test Pilot School in Mojave, California, has a lot of experience flying vintage WWII German aircraft types, and is Flugwerk’s main test pilot. He is also a regular on the European air show circuit. Plasa flew in from Germany on Friday April 24th, and made the first flight on Sunday the 26th.

Klaus Plasa recently answered a few questions from WarbirdsNews about his latest FW-190 flights, and he responded as follows…

WN: How did the flights go, and were there any issues that needed resolving?

KP: The 15 minute flight was a smooth ride. With ground checks complete, a normal take-off and climb to about 6,000ft MSL were eventless. The overall handling characteristics and integrity of the airplane were assessed with emphasis on engine parameters such as pressures and temperatures. Throughout the flight they remained within limits and overhead recovery followed by a landing without any problems concluded this first test flight. The airplane then went back into the workshop, and a thorough post-flight inspection revealed only minor squawks which were immediately addressed.

WN: How does this FW-190 handle in respect to the other FW-190s you have flown?

KP: Normal. It usually takes some time to adjust to the individual layout of the instruments. Overall, it handled like any other Fw 190”

WN: How does the FW-190 handle in comparison to other WWII-era fighters you have flown?

KP: Similar to a Mustang in terms of stick and foot forces, whereas cockpit visibility from a Mustang may be just a little better. Compared to all American fighter airplanes, the biggest difference is the cramped cockpit space due to its tapering fuselage cross-section which makes shoulder and headroom almost touching the structure. The ground handling characteristics of the airplane are rather docile due to its wide track landing gear design (again, similar to a Mustang). The brakes which differ from the original drum brake design, modified by GossHawk to [ed.Red Line] disc brakes, make the airplane handle on the ground without difficulties.

WN: Many thanks indeed for your answers Klaus. Just out of curiosity, can you list some of the more unusual test flights you’ve had to perform?

KP: The widening of the flight envelope of a Messerschmitt Me-163 Komet [ed. An unpowered replica flies in Europe]; conducting the maiden flight of a newly designed micro-light amphibious airplane called the Flywhale; flight testing a solar power, electromotor-driven, proof-of-concept airplane (Solar One).

WarbirdsNews wishes to thank Klaus Plasa very much for taking the time to answer some of our questions, and especially to Lindsey Goss for facilitating it!

FIRST FLIGHT PHOTOS! The following sequence of images by the marvelous photographer Zdenek Kaspar show the preparations for Klaus Plasa’s test flights from pushing the aircraft out of the hangar doors, to taxiing and then the actual flight. Many thanks indeed Zdenek Kaspar!

Once the FW-190 is ready for delivery, it will make its way to Dan Kirkland’s base of operations in Kingman, Arizona. Kirkland will likely visit air shows with the aircraft, but exactly how active he will be remains for the future to determine.

So what’s next for GossHawk? Lindsey Goss says that they are always looking for new work, but that they have several ongoing projects at the moment including the following…

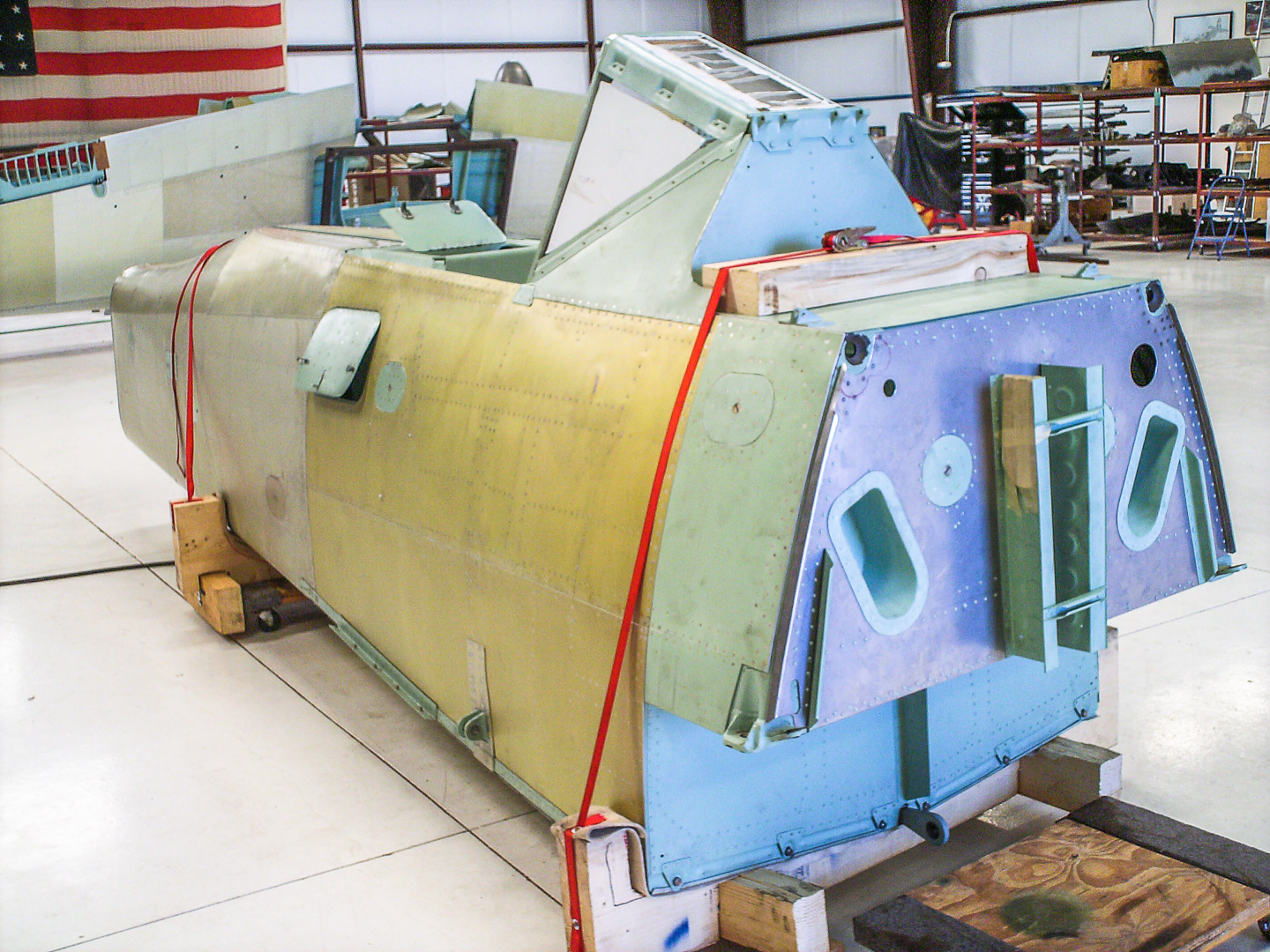

i: We will finish the fuselage for what will be the second original airworthy Focke-Wulf Fw-190 in the world. This is the fuselage for “White 1”, a Focke-Wulf Fw 190F-8 [for the Collings Foundation].

ii: We will continue to restore and maintain the only flying Consolidated PB4Y-2 Privateer in the world. Right now our focus is on keeping her running in optimal condition, and getting together a good fly-away kit for the long journey to Oshkosh this summer.

iii: There is a possibility that we may do a static Nakajima Ki-43 “Oscar” project based upon the remains of the examples recovered some years ago from the Kurile Islands.

iv: We have now brought the Erco turret up to operational condition. We will see how much further we will go with this turret. Depending on the owner’s wishes, we may now take it apart and restore all of the components, repair/replace the skins, and install Plexiglas.

v: We also have our maintenance work that continues in the shop including a Shorts Skyvan and a couple of Shorts C-23B Sherpas. This is not usually the kind of aircraft that we take on, but we like their mission. They train Special Forces. We also maintain a couple T-28s, a T-6, P-51 and a Chipmunk for private customers.

WarbirdsNews wishes to thank everyone at GossHawk Unlimited for their help in putting this article together, but especially to Lindsey Goss, who has been invaluable in its production. Congratulations to GossHawk Unlimited and to Dan Kirkland for a magnificent effort to get another ‘Butcher Bird’ in the air! We look forwards to continuing our reports from this vibrant warbird restoration facility in Arizona in the near future!

My cousin was a P-47 pilot in Europe during WWII, unfortunately he did not make it home. I am always interested in aviation history. As a 30.yr USAF veteran , I experienced a lot of it.

Your circuit brakers for com 2 CONT and CONV do not match the layout on the image abow the panel. Just a heads up.

Sadly, the undercarriage doors do not look correct to me. Look at any wartime photo of any FW190 – the shape at the bottom looks nothing like what is on the Gosshawk bird. Hate to be a nitpicker, but this is a significant visual cue for this aircraft and it’s a real shame that it is so wrong.

Why is it airborne with the pilots step out? Was it left there by ground crew or popped out in flight?

great job god bless u rog