WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this past month!

Fuselages

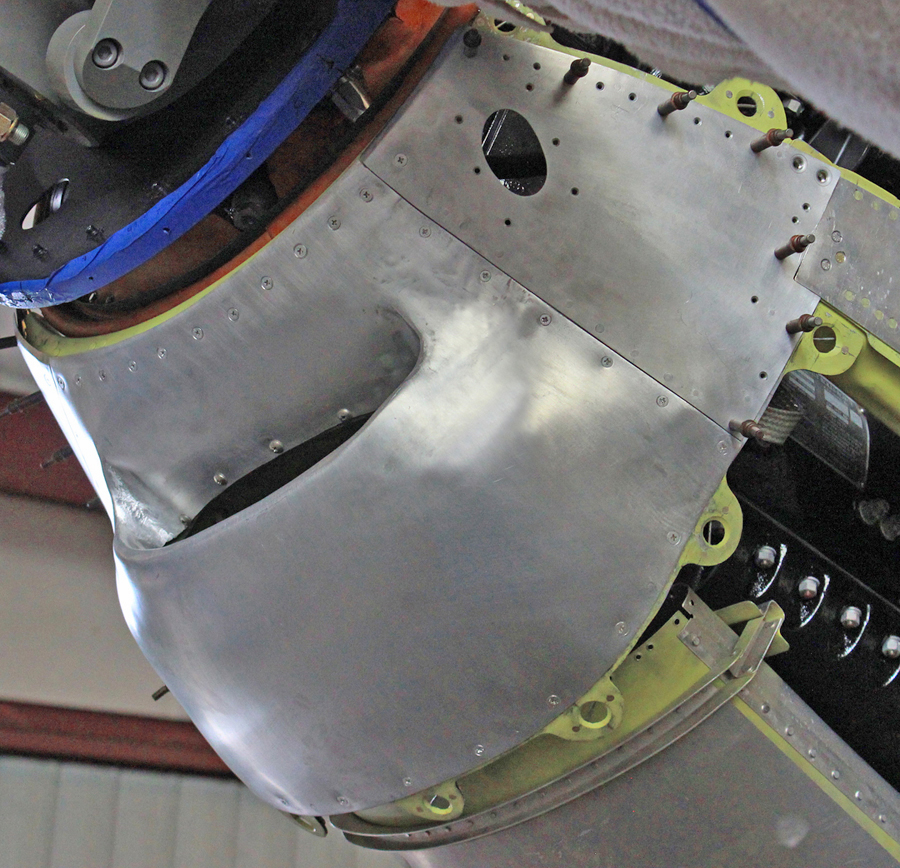

The team has spent a lot of time final-fitting the rotating carburetor air temperature mechanisms, along with the air intake lips and the four side panels.

As mentioned last month, all of the lower and side engine cowling panels are now completed. The final shrinking/stretching, English wheeling and Yoder hammer forming of the top two, right-hand engine cowlings will be completed during January. The left-hand, top panel for the right-hand engine is now final-formed and fitted. The right-hand top panel still needs a little more stretching and wheeling.

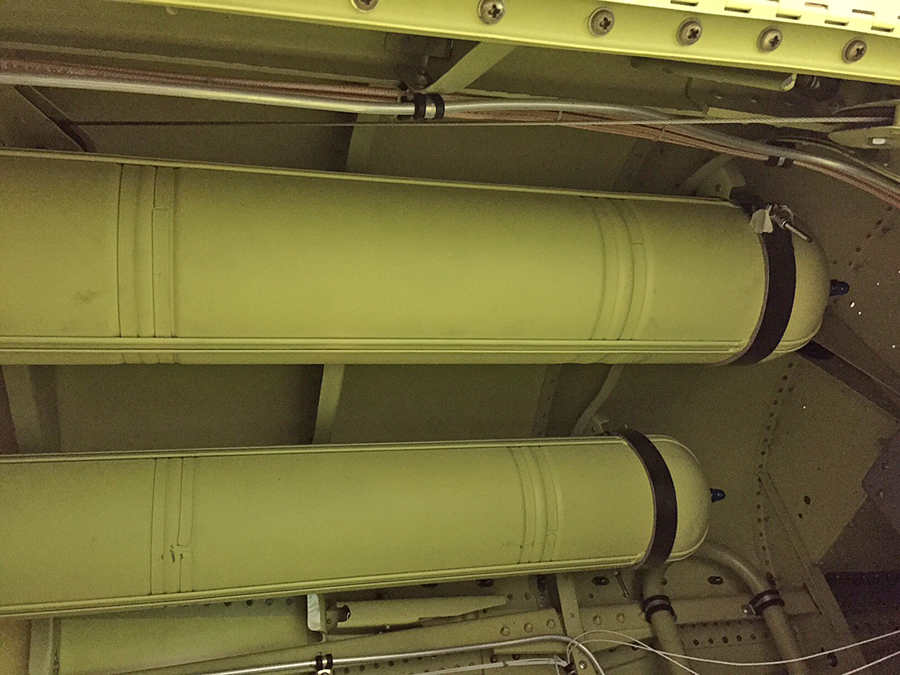

Trying to find the original routing of the oxygen system tubing was a challenge, as all of the available plans show extremely stylized drawings which contradict each other. Thankfully, the restoration crew was able to locate the drilled holes in some of the rejected original side ribs, allowing them to determine the proper location for the line clamps. They were in dramatically different locations to those shown in the stylized drawings. Reilly was also able to source some New Old Stock, four-way Schrader check valves to install, which will help maintain the authenticity of the O2 systems.

Team members are currently working on how to install the gun sight in the left-hand cockpit and the gun strike camera in the right-hand cockpit, but it is a slow process. Trying to put everything back into this XP-82 exactly as it was on day of its first flight, April 15th, 1945, is excruciatingly time consuming.

Gear Doors

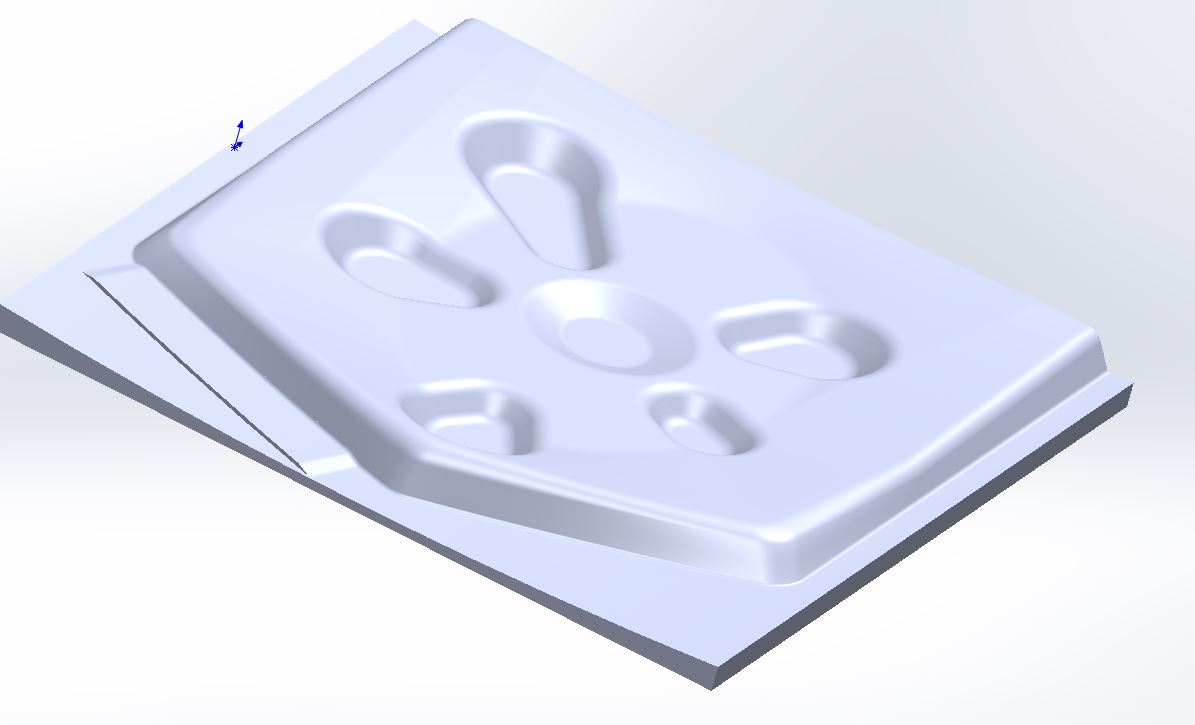

The preliminary forming dies for the main gear center section doors are now complete. The internal pressed skin for each door is a mirror image of the other side. Many hours of machine shop computer work went into these press die patterns. These two center section gear doors are two of the last four major items to complete on the XP-82’s restoration.

Control Surfaces

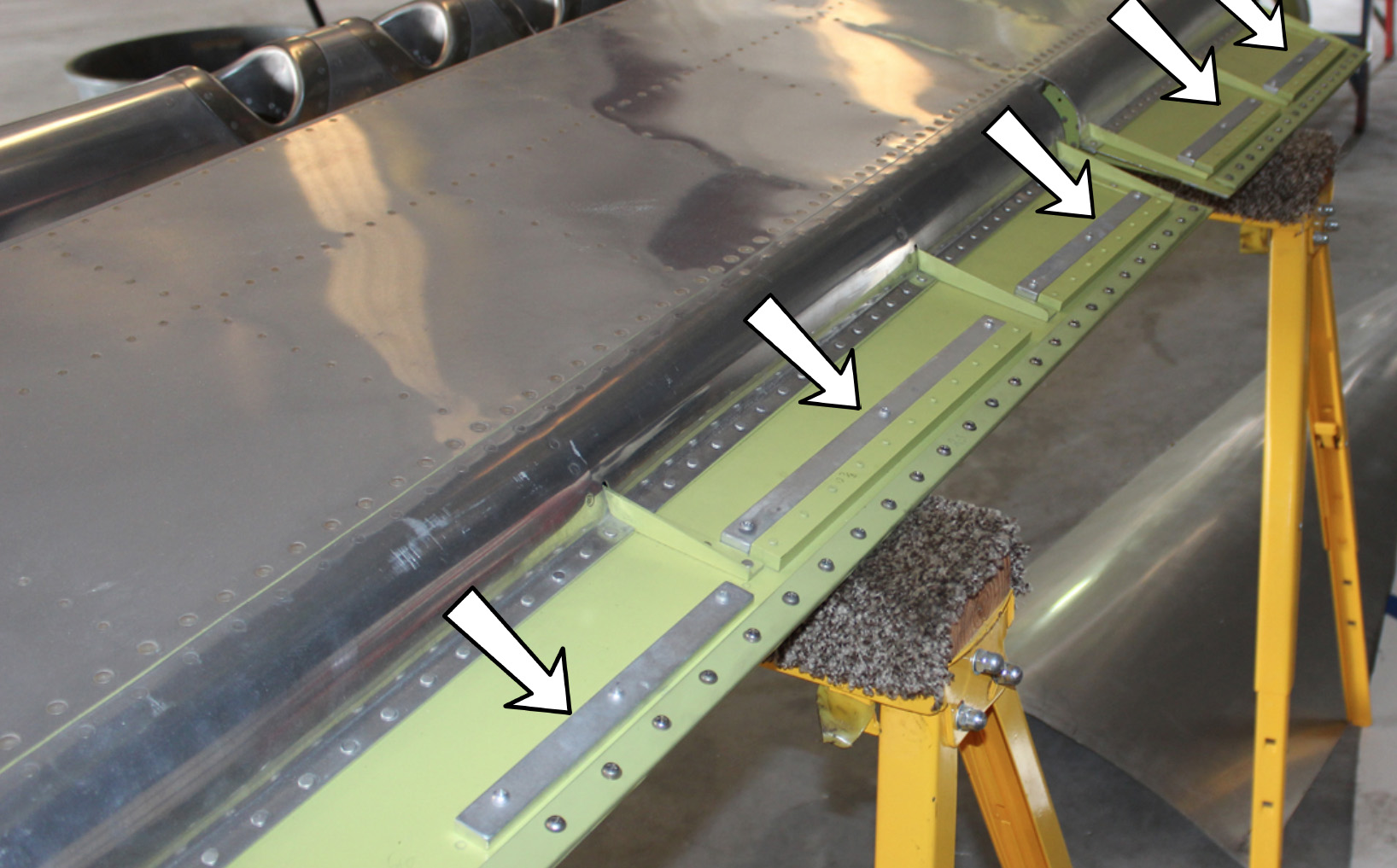

The final balancing of all the control surfaces – the four ailerons, two rudders and one elevator – is now complete. Aircraft control surfaces must be precisely balanced – in accordance with the XP-82 Erection & Maintenance Manual – equal weight forward and aft of the centerline of the hinge points. If they are not balanced properly, they can flutter in flight – much like a flag in heavy wind – and this can lead to catastrophic failure of the part. The restoration team needed to add supplemental leading edge weights to each control surface, because they had replaced all of the hinges, trim tab fittings and trailing edge strips using a much stronger and heavier weight 7075 T6 aluminum alloy in place of the lighter original cast-magnesium components. Trim tab fitting failures due to fluttering in high speed flight have lead to fatal accidents, so getting the correct balance is essential.

Wingtips

Three of the four formed wingtip skins are now finished, with the fourth due due for completion this week. When the parts are ready, the project’s professional welder in Florida will TIG weld (tungsten inert gas) each pair of wingtip halves together. He will match exactly the TIG welding bead pattern of the original wingtips.

And that’s all of the news for December, 2016!

———————————-

Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in February, 2017 for the next installment in the story following the XP-82′s road to recovery!