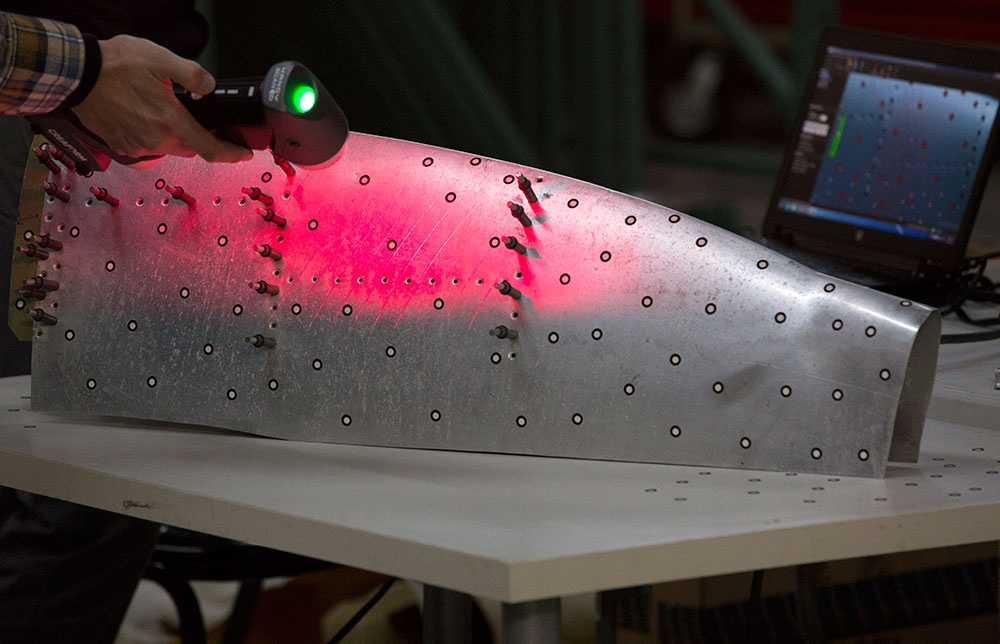

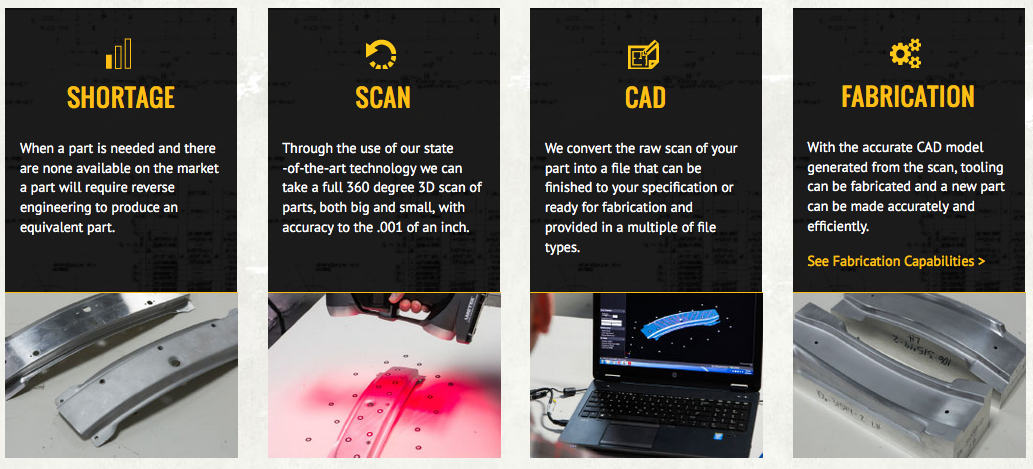

AirCorps Aviation is redefining WWII Aircraft Restoration & Maintenance to allow aircraft built in the 20th Century to fly through the 21st Century. The renowned Bemidji, MN based vintage aviation company, has introduced a new service for its clients called AirCorps Aviation Reverse Engineering which uses state-of-the-art technology that allows for accurate scans of parts, both big and small, that can be used for the fabrication of new parts and inspection of original parts.

The process saves both time,money, and produces highly accurate results compared to traditional methods. Accordingly to Erik Hokuf, co-founder of AirCorps Aviation, told Warbirds News: “We can all think of parts that are needed for restoring and maintaining our vintage aircraft that seem to be unobtainable and impossible to make. A common reason the part is impossible to make is because the part was made by craftsmen using techniques or machinery that are just as rare. With the addition of the 3D scanner to AirCorps Aviations machinery list, we can now digitally model these complex parts, drawn with a slide rule on pencil and paper, very accurately and efficiently. With this scanner we can combine the best of both the factory drawings and the actual dimension of an original part to make a replacement part that truly fits.”

There are several possible applications such as outside contour development ,parts reproduction lacking dimensional drawings ,preservation recording, quality control, damage assessment, aircraft dimensional tolerance and straightness, part reproduction, propeller blade inspection, corrosion inspection.

Hi. Is there any reason why the US have never converted to the metric system of measurement ? I find it intriguing when I see or hear terms such as “accuracy of .001 inch “.

Mmm, now that I’ve asked the question – you could of course reply that the Brit’s use miles rather than Kilometres !

Thanks

Murray (UK)