By James Kightly, Commissioning Editor

The Shuttleworth Collection, Biggleswade, Bedfordshire, UK, has a number of genuinely unique surviving aircraft, and some of those are powered by the only working example of the engine type. Such is the 1928 Hawker Tomtit RAF trainer and its rare Armstrong Siddeley Mongoose five-cylinder radial engine. Both the engine and aircraft are the only surviving active examples, anywhere.

In 2018, the aircraft was grounded after issues were found with the Mongoose engine. While the cylinders of the engine are the same type as the 300 – 400hp 14-cylinder Armstrong Siddeley Jaguar engine, parts for these 1930s era engines either are rare to non-existent, of course. Shuttleworth Engineer, Gareth Rutt, spent the last four years rebuilding the engine so this unique combination could fly again.

During this time the master rod has been re-white metaled, together with the manufacture of a new cam pack, magneto drive gears and new tappets. The carburettor and oil pump have undergone an overhaul and all other parts have been cleaned, measured and refitted along with an engine rebuild. The Tomtit flew again on 16 June 2023 at the hands of Chief Pilot Paul Stone, precisely five years after its last air show appearance.

After the flight, and further checks and paperwork, the aircraft, painted as K1786, and registered as G-AFTA, was given the required release of a Permit to Fly, and it featured in the Carnival Air Show at Shuttleworth’s grass airfield at Old Warden on Sunday 6 August, and the September opening show.

A Detailed Engineering Insight

We reached out to the collection to share with us a more detailed rundown of the work undertaken on this unique engine. Matthew Chapman, Airworthiness Support Engineer at Shuttleworth shared the following details:

“Before the engine rebuild, the Hawker Tomtit last flew an air display at Shuttleworth on the 16th June 2018. Two days later the aircraft was brought in to the Engineering Hangar at Old Warden for its routine ‘Annual Inspection and Maintenance’. During the inspection the oil filters were checked and we found excessive white metal particles. It’s not uncommon to sometimes find particles, but this was too much to ignore and the decision was taken to remove the engine from the airframe and strip it down for investigation. Being white metal, we suspected the big end bearing shells, and so it turned out to be. The ‘white metal’ on bearing shells of this kind acts as a hard wearing surface so when it starts to degrade you run the risk of overheating and engine seizing.

“As with all our engine rebuilds we do the work ‘in-house’ using our team of experienced engineers. We have the capabilities to do a lot of work and we have our own machine shop, but some items we knew we would probably have to engage external sub-contractors.

“The Tomtit is powered by the last remaining airworthy Armstrong Siddeley Mongoose seven-cylinder radial engine dating from the 1920s (approaching 100 years old). We have some spares (and one spare, static, engine) but not very many spares, so we knew this would be a challenging project. (According to the records we have it is a Mongoose IIIC, a military version based on the Mk IIIA.)

“And so began the complete disassembly of the engine. With the engine disassembled, we began the task of inspecting all components and measuring those against the ‘Schedule of Fits and Clearances’ from the ‘Instruction Book for Armstrong Siddeley Radial Aero Engines, Mongoose IIIC later type’.

“Following this work, we identified a number of components or sub-assemblies which were worn beyond the book limits, or were visually worn, or in generally poor condition and required replacement. At this time, the engine had done a total of 759 hours and 45 minutes, with 48 hours and 25 minutes since the last overhaul. The aircraft operates on a ‘Permit to Fly’ here in the UK and is under the control of the Light Aircraft Association. Working with the LAA, we had to apply for some approved modifications in order to manufacture new parts. These were as follows:

- New inlet and exhaust valves to be manufactured under an approved modification, as no spare parts were available and the original material is now obsolete. Modification required for the change to a modern material. This all went quite well.

- New tappet shafts were required to be manufactured under an approved modification to take into account the use of modern materials. Again, this all went quite smoothly.

- New steel cam gears (for driving the cam drum) and bevel gears (for driving the ignition magnetos) were also required to be manufactured under an approved modification to take into account a change to modern materials. This became more troublesome, see below.

“This process was going quite smoothly until the coronavirus pandemic hit us in April 2020, although it had been over 18 months since the start of the project – so you can see how much time is involved. The pandemic and the various lockdowns we experienced in the UK delayed things further. Our working time was reduced in 2020 and 2021 and various other things took priority: such as re-opening the site, and trying to do ‘drive-in airshows’ when we were allowed to try and bring some cash back in to The Collection.

“Also during this time we had real problems with the company making the gears for us. The bevel gears in particular were hard to have drawn up into a CAD model, and then they were difficult to manufacture. The company we were using had an engineer sadly die during the pandemic, and another retired (or left the company), and eventually the machine they used to cut bevel gears broke down. As they didn’t have enough other work for it, they opted to decommission it, so they couldn’t complete the job! We had to start almost from scratch and engage with another company that could make the bevel gears. Luckily they turned out to be good, and once we had received all the new parts we could begin reassembly.

“In the meantime we did a lot of other work in-house, like overhauled the carburettor, the oil pumps were overhauled, and new ignition cables made, etc. The big ends were re-white metalled by a supplier and the con rods were re-used. All the cylinders were worn beyond limits, so we used cylinders from our spare engine. That means that next time we will have to have new cylinders made, as we now have no spares whatsoever!

This time-lapse video captures the moment when the world’s only Armstrong Siddeley Mongoose engine was fitted into the world’s only Hawker Tomtit. [video by The Shuttleworth Collection]

“The final assembly of the engine was done during 2022 with the first engine running in November 2022. Over the winter of 2022 – 2023, we then had the task of submitting all the paperwork to the LAA, in order for them to grant us a ‘Permit to Test’ to allow Paul Stone, our Collection’s Chief Pilot to conduct a test flight. The first test flight was twenty minutes here at Old Warden on 16th June 2023. Since then, it had further testing and subsequent inspection of the new components and of the engine more generally. So far so good, and she has now completed displays in two airshows this summer and is due to display again here on Sunday 3rd September 2023.”

The Hawker Tomtit’s History

The Hawker Tomtit was an inter-war British trainer aircraft, designed by Sydney Camm (of later Hurricane fame) to replace the old Avro 504s still in service in the mid-1920s.

Despite building a batch for evaluation, the trainer the Royal Air Force (RAF) chose was the Avro Tutor (the sole surviving example of which is also in the Shuttleworth Collection!) so ultimately only 36 Tomtits were built for the RAF, and production and ex-RAF examples being civil registered for test work and private owners. Two went to Canada for the Royal Canadian Air Force and four to the Royal New Zealand Air Force.

It would have been nothing more than a footnote in history, if famous race and test pilot Alex Henshaw hadn’t managed to obtain Tomtit, civil registered as G-AFTA in 1941, during the war while test flying production Spitfires as his ‘commuting’ aircraft. He had it fitted, bizarrely, with a Spitfire windscreen. G-AFTA was, in fact, the last Tomtit built, as K1786, and had been sold to the civil market in 1935.

Sold postwar for £250, it was used for glider towing before being bought in 1949 by Squadron Leader Neville Duke, another famous record and test pilot, who flew it in several air races and displays before he sold it to Hawker Aircraft Company in 1950, joining their airworthy Hawker Hurricane and Hart. When Hawker’s divested themselves of their flying historic aircraft collection, the Hurricane stayed airworthy with the Battle of Britain Memorial Flight, the Hart being grounded at the RAF Museum (which opened in 1972), and the Tomtit going to the Shuttleworth Collection.

Flown in Hawker’s house colors of a sharp blue and gold civil scheme, in 1967 it was returned to its original military scheme by Hawker Siddeley. It has been operated by The Collection from Old Warden, ever since, though, as well as the recent grounding for the aforementioned engine rebuild, it was grounded for several years after an accident at the Air Fete at RAF Mildenhall in 1985, when, landing on a temporary grass ‘runway’ it hit a hidden obstruction, with the propeller and undercarriage being smashed.

While the undercarriage repair was relatively straightforward, finding another propeller of the necessary rigidity proved a problem, with the replacement propeller flexing significantly out of true. This was found to be due to harmonic vibration between the engine and propeller. Much experimentation and even appeals to the public for video showing the propeller ‘in action’ prior to the accident failed to resolve the problem. It was eventually solved by Hoffman of Germany who provided one with the hub made of compressed beech veneers with spruce laths spliced in towards the tips, then covered with a carbon fiber and epoxy coating with an integral leading edge.

In the early 2010s, the aircraft underwent a major overhaul and re-fabric, with then Chief Pilot ‘Dodge’ Bailey taking the Tomtit aloft for its first shakedown flight after complete restoration, on 19th June 2014. Without the details being recorded, it would be all too easy to just assume the Tomtit and its Mongoose engine was ‘just ‘part of the scenery’ at Old Warden, and ticked along year in, year out – while in reality it only flies thanks to generations of dedicated workers and their ingenuity.

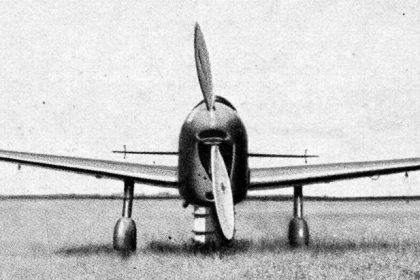

The Armstrong Siddeley Mongoose of 125 hp is a left-hand tractor air cooled static radial. The five cylinders have a bore of 127 mm (5 in) and stroke of 140 mm (5.5 in). The normal RPM is 1620, with a maximum of 1780. The brake horse power at normal RPM was 125, at maximum, 150. The cubic capacity is 8,868 cc, and the fuel consumption 7 gallons per hour. The weight is 337 lbs, giving a weight to power ratio of 2.7Ibs per hp.

The design was a medium-power five cylinder engine of similar design to the company’s successful Jaguar and Lynx engines. It has the same bore and stroke and many of its parts are interchangeable with those two other engines. They are the cylinders, pistons, piston rings, gudgeon pins, valves, valve springs, rocker gear, push rods, tappets, tappet guides, and propeller boss. The cylinders are of composite construction and comprise aluminium (being British!) heads, head locking rings, steel barrels and barrel locking rings. Steel sockets accommodate the cylinders in the crankcase.

As well as the Tomtit, the Armstrong Siddeley Mongoose was used in the Avro Gosport; Fokker S4; Avro 504N; Handley Page Gugunc (the sole example built surviving in the Science Museum collection); the Australian twin-engine Lasco Lascondor transport and the Swedish Svenska Aero Falken.

Thanks

We would like to thank Matthew Chapman, and the Shuttleworth Collection, for enabling an insight into what is required returning a unique engine and aircraft type to the air. The Collection always appreciates support, and the main supporting organisation is the Shuttleworth Veteran Aeroplane Society, which both fundraises for the collection and shares these levels of insight with interested enthusiasts through their excellent magazine ‘Propswing’, plus other ‘perks’. You can join the SVAS here.