As Tom Reilly just said, “Another month flew by. That light at the end of the tunnel is getting brighter each day!” WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this month!

Firewall Forwards

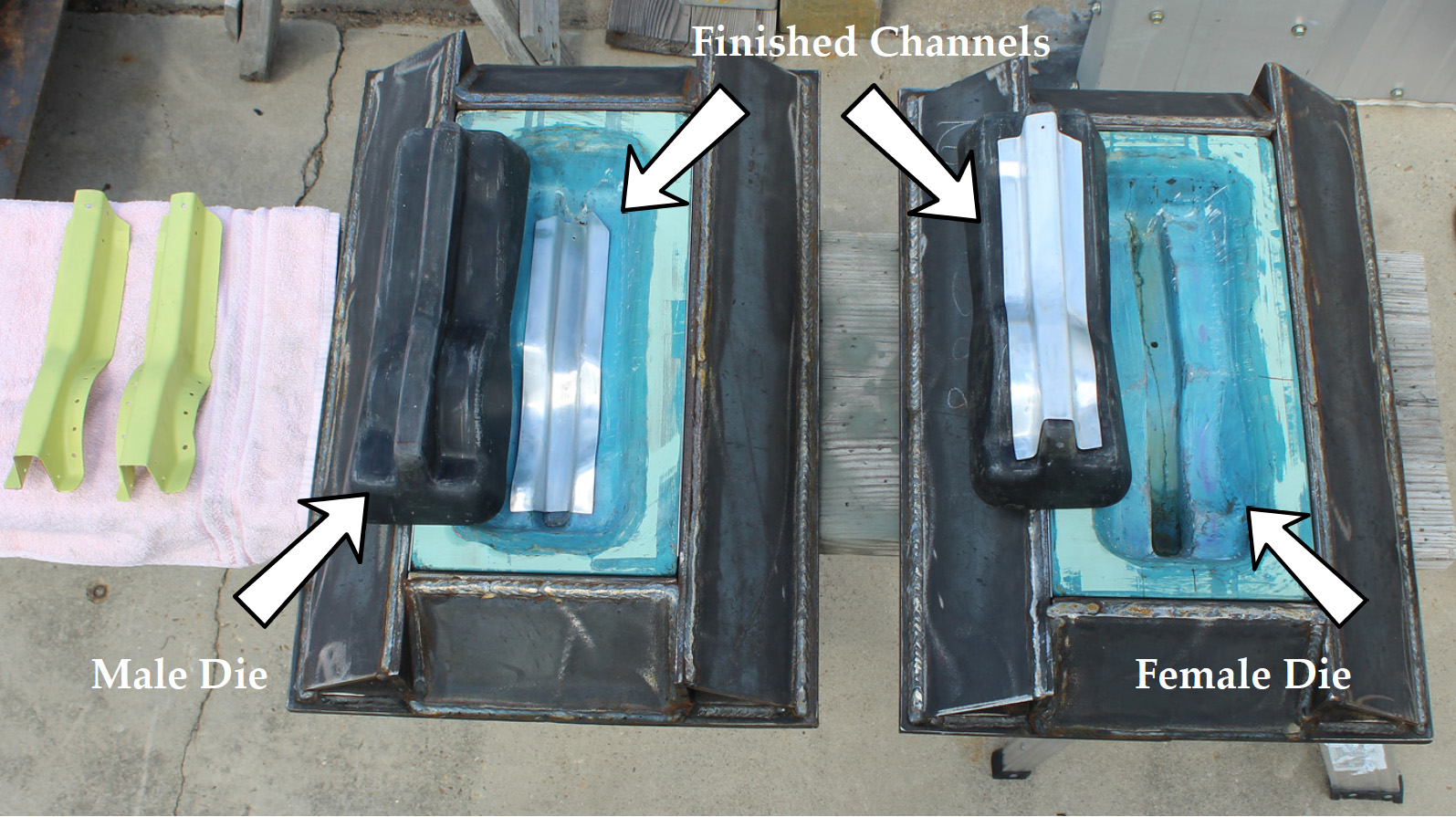

Much effort has gone into the forming and fitting of the carburetor air temperature rotating cylinders and housing brackets that mount these mechanisms. The restoration team had to make male and female dies to press the complicated and extremely deep-draw mounting channels. With these mounting channels completed, the team is now working on forming the lower carburetor air intake lips. Tom Reilly is grateful to Tom Wilson for the excellent press job.

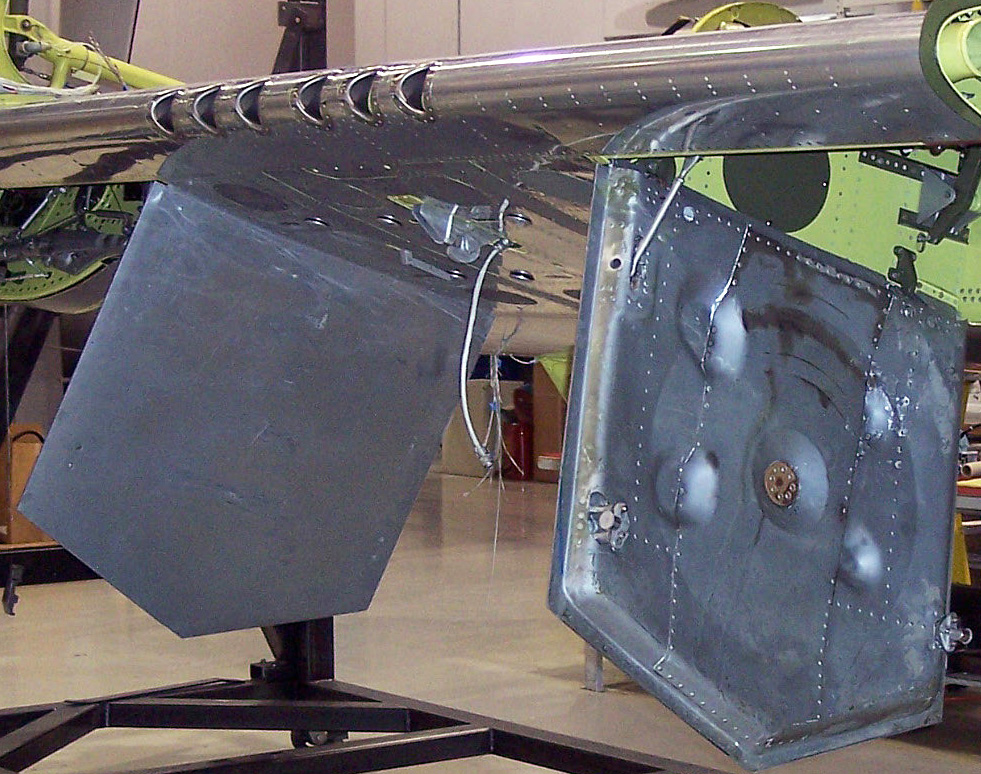

The final-fitting of the press-formed stainless steel exhaust fairings is now complete, and the team is flush riveting the parts to each side cowling.

The freshly-sewn and perfectly copied cushion mounts for the oil tanks are now attached to the tank mounts.

The team has test-fitted the two stainless steel dishpans into the steel armour firewalls. All of the wired electrical Firewall Forward Cannon plugs, generator shunts and shielded magneto harnesses are complete. Reilly’s team has also fitted the components.

Electrical

The restoration team applied electrical power to the ship for the first time last week and began testing each circuit. The final hookup of all the instrument panel Cannon plugs is now complete. The final checkout of the electrical circuits through both wings is also done.

Gear Doors

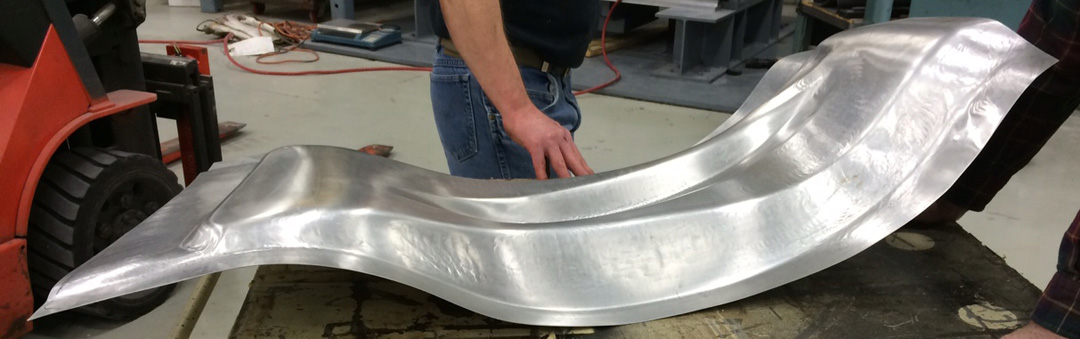

Pat Harker’s shop in Anoka, Minnesota is working on their own F-82E Twin Mustang and has been collaborating with the XP-82 project over the years. They are currently manufacturing the two outboard serpentine gear doors that are needed for the XP-82. These doors have an extremely deep-press internal skin that has created challenges, but Pat and his team have perfected this deep-press procedure and successfully produced these flawless internal skins.

One of Tom Reilly’s subcontractor machine shops is currently completing the pressed inboard door skin forms. Reilly had previously recovered two extremely damaged internal gear doors from the Alaskan wreck site. Looking at other, undamaged doors has allowed him to get patterns and measurements for making a new set. With this data, the machine shop is in the process of milling the press fixtures that they will use to press new internal skins for the doors. These very large internal doors are two of the last complicated parts needed to complete the XP-82 restoration.

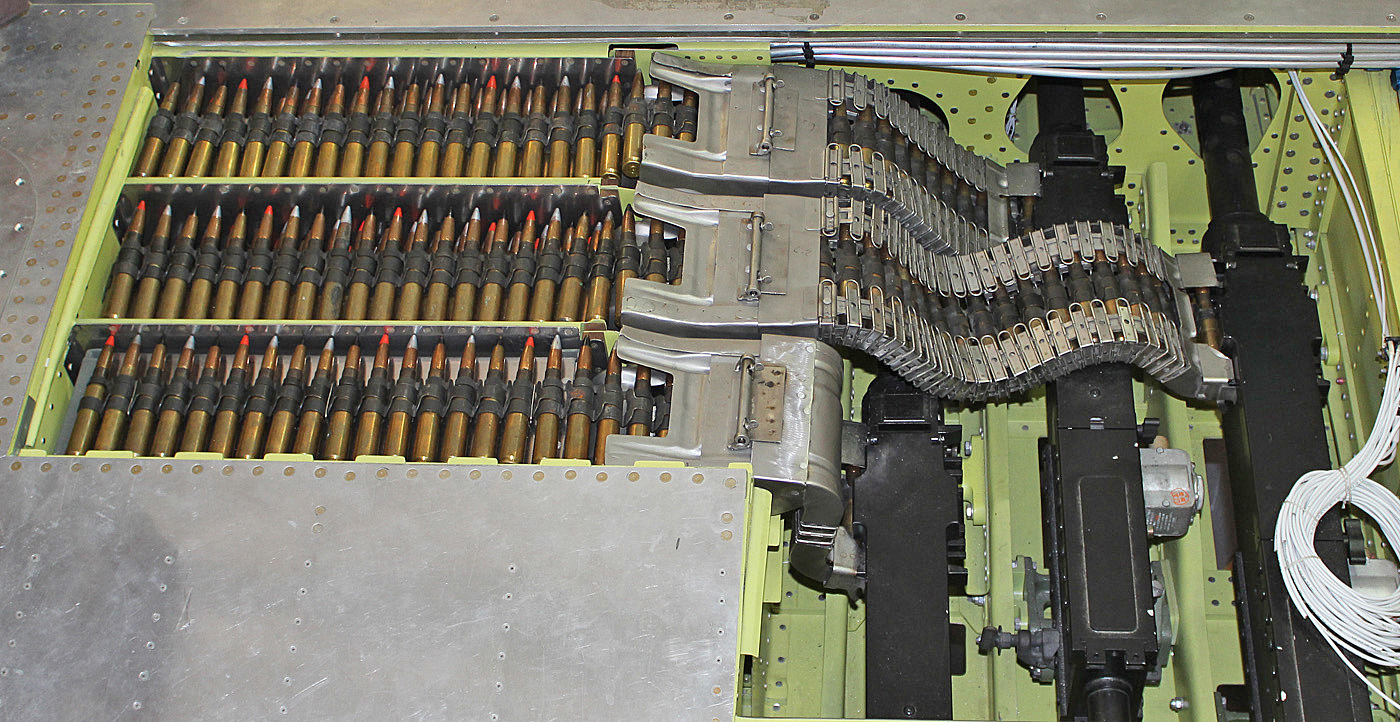

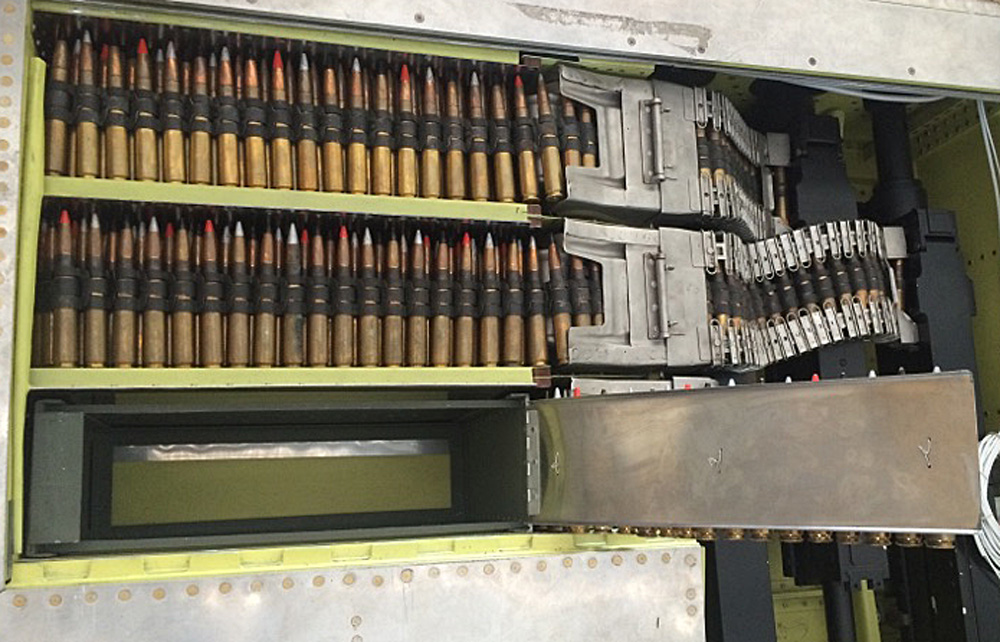

Gun Bays

The following images should illustrate the work going on in the gun bays.

Tail Gear

The tail wheel assemblies are now complete with the exception of the tail steering arms and cables.

Moving

The restoration team will be moving the XP-82 into a large hangar across the field in mid-September so they can install the outer wing panels and complete the remaining work on the aircraft. While in this hangar, they will install the propellers and test the undercarriage retraction too. The final stretch to finishing the XP-82 Twin Mustang restoration is within grasping distance now!

And that’s all of the news for August, 2016!

———————————-

Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in October for the next installment in the story following the XP-82′s road to recovery!

Keep up the great work guys – I can’t wait to see the Twin Mustang rolled out!

Thanks for always keeping us in the loop! Team XP-82 bringing history to life!

That’s not an airplane. That’s jewelry worthy of Tiffany! Beautiful craftsmanship to a “T”.

Bloody awesome work done, lot of hard yakka so far but what a beautiful aircraft, I’m down in Werribee Australia and our people down here are trying to bring a B24 liberator back to life, I wish and all your associated people safe miles to you and all your loved ones

John Hancock. P.s the name is ridgy didg

Awaiting moderation?

My jaw drops whenever I get a chance to get caught up with this restoration. Beautiful craftsmanship!