Over the past six months, the restoration team working on B-17E Desert Rat (s/n 41-2595) in Marengo, Illinois, has continued to push forward with painstaking efforts across several fronts—despite seasonal slowdowns and the ongoing challenges that come with reviving such a historically rare aircraft. Project lead Mike Kellner and his dedicated group of volunteers, including longtime contributor Bill Riedel, have made incremental yet significant progress, from structural repairs to system reassembly and even a few side projects that help support the broader restoration environment. But before we share how you can help, we thought you’d enjoy a recent conversation with Bill Stanczak, a dedicated volunteer and project manager with the FAA. Monetary donations can be placed HERE.

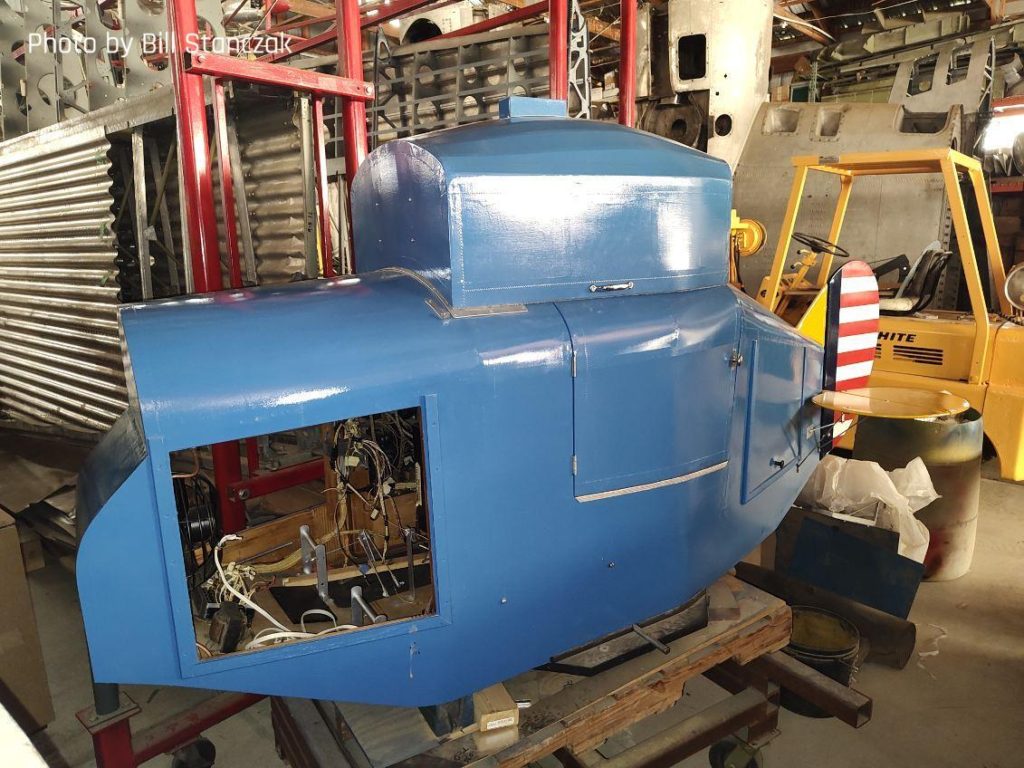

Cockpit and Nose Section Progress

One of the primary areas of focus since the last update has been the aircraft’s nose section. Volunteers have continued fabrication work on the complex nose frame, including the installation of new glass. As with many aspects of this project, custom parts and rare fittings have proven difficult to source, often requiring the team to machine them from scratch. Lead times for specialized extrusions—often exceeding 20 weeks—continue to slow progress, not to mention the steep costs involved.

Meanwhile, inside the cockpit, Mike and Chris have been working to reinstall control pulleys that route cables for the aircraft’s control surfaces and engine systems. Since many of these components were originally installed before the outer skin was added during factory assembly, accessing and fitting them post-restoration has been particularly tricky.

Tail Wheel and Structural Components

At the rear of the aircraft, progress has been made on the metal tail wheel well and surrounding structure. The shroud and walkway platforms around the wheel assembly have been riveted in place, with rubber surfacing to be applied closer to project completion. On the subject of landing gear, the team is expecting the return of the refurbished tail wheel assembly and main gear oleo struts in the coming months. A fellow restorer has been assisting with this rebuild and plans to deliver the components from out of state—another example of the collaborative spirit that fuels this ambitious effort.

Vertical Stabilizer Nearing Completion

The Desert Rat’s vertical stabilizer has long been nearing completion, and as of this spring, it’s just about ready for paint. The remaining tasks include installing the closeout panels—small curved fairings located just forward of the rudder—which are attached using rivnuts. Volunteers have been busy fitting these, and once the navigation lights are wired and installed, the entire vertical fin will be essentially finished.

Link Trainer, and a Willys Jeep Off the aircraft, other pieces of WWII aviation history are also coming back to life. A 1942 Willys Jeep—originally part of the restoration hangar’s support equipment—recently received a replacement “Go Devil” engine after the original was found to have a cracked block. The team sourced a replacement engine from Wisconsin, which is now en route to a Jeep restoration shop for overhaul.

Meanwhile, the project’s Link Trainer—a WWII-era flight simulator—has also seen impressive restoration progress. Volunteer John has been working on the trainer one or two days per week for several years. The airframe and tail surfaces have been recovered and painted, and many of the internal mechanical and electrical components have been restored, including the vacuum turbine and Telegon Oscillator. Two of the project’s three Link Trainers are now partially functional, while the third is being cosmetically restored for potential display or resale.

Desert Rat also has its own dedicated Facebook page HERE which some of our readers may enjoy viewing too. If you wish to contribute to the restoration of this important aircraft, whether it be with parts, labor or cash, please contact the Desert Rat team HERE. Monetary donations can be placed HERE.

I have a com please SCR-274-N ( B-17 liaison radio) complete 2 transmitter, 2 receiver with modulator and antenna relay box set up with all wiring and remotes, repaired but not modified, in working condition with manual, if you have any interest in it.