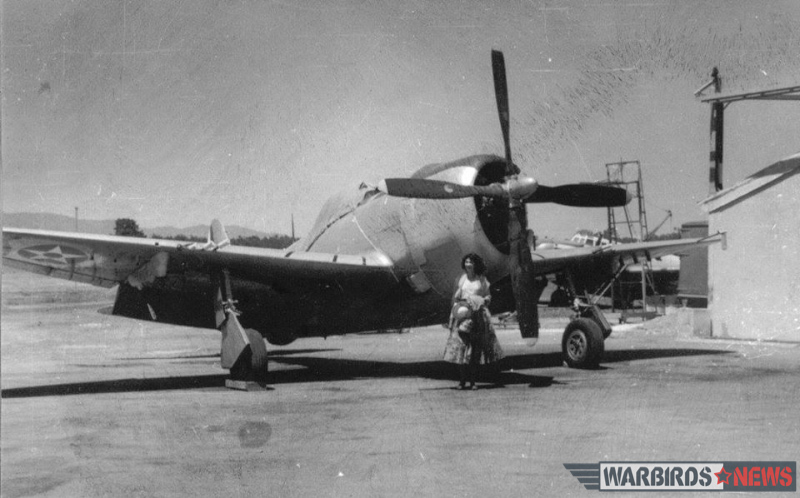

In November 2024, we shared an update on the restoration of the Commemorative Air Force (CAF) Airbase Georgia’s Republic P-47N Thunderbolt (S/N 44-89136). Since then, the dedicated volunteer team at Falcon Field in Peachtree City, Georgia, has continued their expert efforts to return this iconic WWII fighter to the skies. Although this particular P-47N was delivered too late to see combat during the Second World War, it has a fascinating post-war history, having served with the Guatemalan Air Force—a story we covered in detail back in December 2016.

Recent restoration efforts have focused on the aircraft’s electrical wiring and hydraulic systems. The team has also re-chromed several hydraulic cylinders and fully disassembled, cleaned, and overhauled the tailwheel assembly.

A major milestone has been the complete restoration of the aircraft’s main landing gear. The P-47N features a robust, hydraulically operated, full cantilever landing gear system, composed of independently functioning right and left shock strut assemblies. These assemblies include air-oil combination struts and high-pressure cast magnesium wheels with drop center rims. Each shock strut is mounted within a magnesium box-like structure that fits into a compartment formed by structural ribs 86 and 104 and the landing gear auxiliary spar. These components are secured with four bolts through each rib and adjoining plates.

Retraction of the landing gear begins with hydraulic pressure withdrawing a nitrided steel downlock pin from the locking arm of the strut. A sequence valve then opens to allow hydraulic pressure into the retraction cylinder. During the retraction cycle, the piston within the shock strut telescopes into a bottomed-out position, allowing the gear to fit into a bay that’s 9 inches shorter than would otherwise be required with a conventional retraction system. This is made possible by a “shrinkage strut” mechanism that adjusts the geometry of the strut assembly as the gear retracts. As the piston compresses, air displaced from the shock strut’s air-oil chamber is redirected into an auxiliary air chamber located above it. A push rod connected to a cam track above the strut activates a valve to open this auxiliary chamber, allowing for the air transfer.

As the restoration of the P-47N Thunderbolt advances, the skilled team at CAF Airbase Georgia continues to tackle a broad range of critical tasks. Restoring such a complex and historically significant aircraft presents unique challenges, prompting close collaboration with warbird restoration experts across the country, such as AirCorps Aviation. While this outside expertise is essential for certain aspects—particularly precision metalwork and the fabrication of rare or hard-to-source components—Airbase Georgia is also uniquely equipped to handle much of the work internally. In fact, the unit boasts one of the most capable machine shops within the entire CAF network, allowing volunteers to fabricate many parts in-house. Among the components currently being produced are the intricate latching mechanisms for the gun and ammunition bay doors, which must meet exacting standards to ensure both historical accuracy and mechanical reliability. Every step of the project reflects the team’s unwavering commitment to craftsmanship, authenticity, and the ultimate goal of returning this legendary fighter to the skies.

One key component still needed to advance the restoration is the rudder bar assembly, including the pedals and related hardware. If you know the whereabouts of these parts or can assist in locating them, please contact CAF Airbase Georgia. The restoration of this P-47N is a demanding and resource-intensive undertaking, but the team is making steady progress. If you’d like to support the return of this legendary fighter to flight, [click here] to learn how you can contribute to preserving this important piece of aviation history.