By Scott Thompson, Aero Vintage Books

Scott Thompson of Aero Vintage recently returned from a visit to the Erickson Aircraft Collection in Madras, Oregon, where significant restoration work is underway on several Boeing B-17 Flying Fortress airframes. The collection currently houses three B-17s: B-17G 44-8543 (N3701G), B-17G 44-85829 (N3193G), and B-17G 44-85718 (N900RW). While the first two require only brief updates, the most substantial progress involves 44-85718, formerly known as Thunderbird during its tenure with the Lone Star Flight Museum.

Groundbreaking Wing Spar Restoration on B-17G 44-85718

Aircraft 44-85718 is currently undergoing extensive structural work, particularly to address issues related to its inner wing spar tubes. In recent years, the airworthiness of flying B-17s has been compromised due to corrosion and cracking within the wing spars—issues addressed by two FAA Airworthiness Directives (ADs). In response, the Erickson Aircraft Collection, in collaboration with Scott Glover’s Mid America Flight Museum (current owner of 44-85718), launched a full “Inspect and Repair as Necessary” (IRAN) initiative.

Upon detailed inspection in late 2020, it was determined that replacing—rather than repairing—the rear spar tubes in both inner wing panels was the only viable solution. This ambitious undertaking is unprecedented in the B-17 community, primarily due to the complexity and scarcity of the specialized aluminum extrusions used in the original spar design. Each of the four required spar tubes (two forward, two aft per panel) measures approximately 26 feet in length and features a precision taper to accommodate load and aerodynamic stress, as specified in Boeing’s original 1930s engineering drawings.

After extensive research and vendor outreach, a British manufacturer specializing in aircraft-grade extrusions for European aerospace firms was identified. The tooling and production process took over two years, culminating in the delivery of eight certified spar tubes to Madras by late 2024. Given the limited future availability of this specialized tooling, there is now growing interest within the B-17 preservation community to commission additional units while the opportunity still exists.

The Erickson team has since mounted both inner wing panels in custom-built jigs, based on original Boeing production tooling, to ensure precise alignment during disassembly and reassembly. Removal of the existing spar tubes is complete, and installation of the new tubes is underway. One of the key technical challenges has been devising a method for riveting the tubes—specifically how to apply the necessary back pressure along a 26-foot enclosed space. Erickson’s team has developed proprietary tooling to overcome this obstacle, and they are using original-style rivets to preserve historical accuracy.

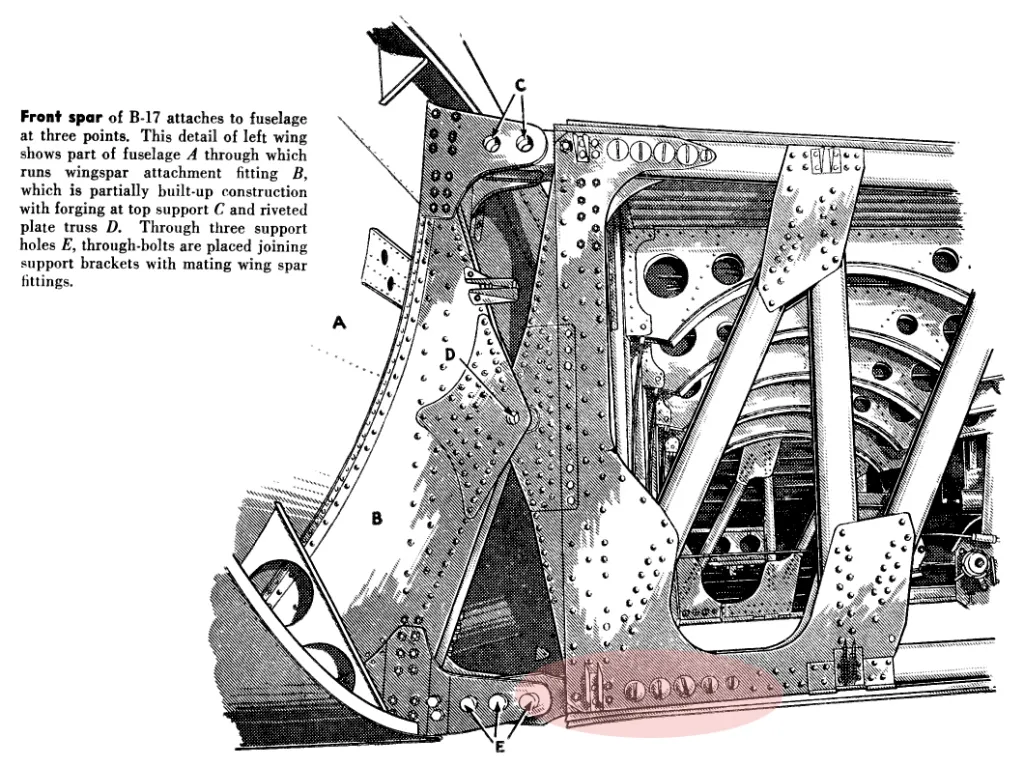

Tolerances in this process are exceptionally tight, as the reassembled spars must align precisely with the fuselage’s wing attach points. These points use close-tolerance bolts, and even minor deviations could compromise structural integrity. Simultaneously, all wing components are being inspected and minor corrosion or structural deficiencies are being addressed.

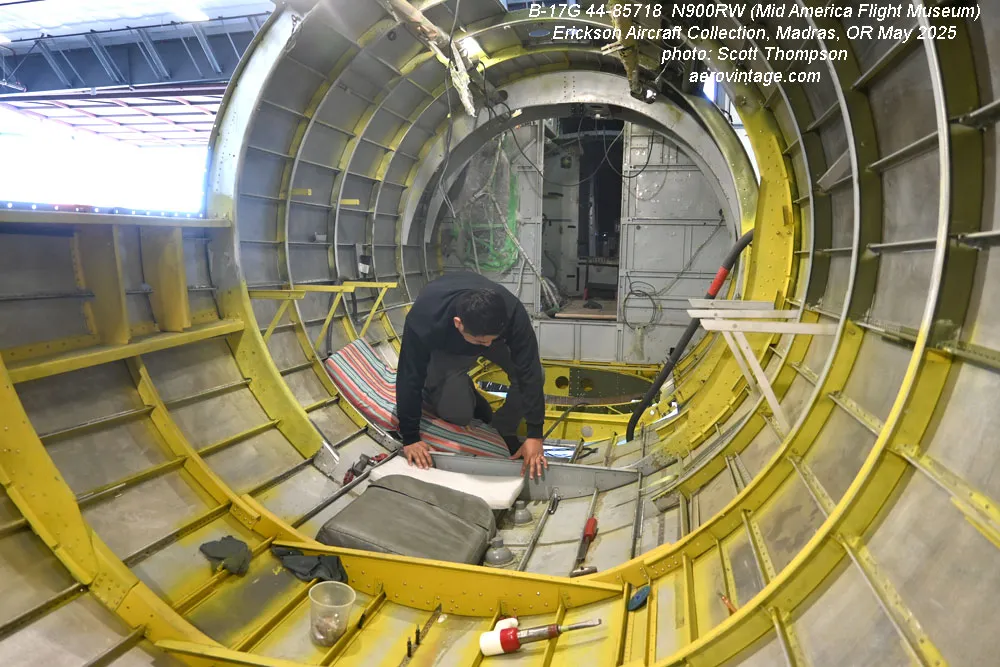

Fuselage Restoration Progress

While wing work progresses, a parallel team is restoring the aircraft’s fuselage. The former Thunderbird paint scheme has been stripped, revealing and facilitating repair of corrosion in the aft fuselage and belly areas. Work is advancing forward from the tail, with repairs completed or underway on internal frames, longerons, and skin. Attention will soon shift to the ball turret and nose sections, culminating in the bomb bay between fuselage stations 4 and 5—home to complex structural components, including wing carry-through fittings.

A point of historical interest is the aircraft’s unique nose configuration. While in service with France’s Institut Géographique National (IGN) from 1947 to 1984 as F-BEEC, the aircraft was modified with a custom plexiglass nose and additional window cutouts for aerial survey work. These non-standard features have never been removed. While no final decision has been made, there is consideration to retain these elements as a tribute to the aircraft’s long career in aerial cartography. Ghosted IGN markings remain visible on the stripped nose skin.

If progress continues as planned, the aircraft may be ready for reassembly within two years. All engines and propellers will be overhauled, and the aircraft systems will undergo comprehensive IRAN procedures. Upon completion, the aircraft will return to flight as part of the Mid-America Flight Museum collection, bearing the name We the People. It will be presented in natural metal finish with standard U.S. Army Air Forces markings, with nose art and squadron insignia yet to be finalized.

Update on B-17G 44-85829 (Ex-Yankee Lady)

The fuselage, wings, and empennage of B-17G 44-85829—formerly Yankee Lady—remain shrink-wrapped and staged for international shipping to Avspecs Ltd. near Auckland, New Zealand. Once at Avspecs, the aircraft will undergo a complete restoration on behalf of the Charles Somers Aircraft Collection, based at McClellan Field in Sacramento, California. Currently, the inner wing panels are stored in Erickson’s hangar awaiting their turn in the jigs once work on 44-85718 is complete. Detailed spar inspections will determine the extent of necessary repairs, which may include similar spar tube replacements depending on condition. The full restoration is expected to take several years but will likely result in another airworthy Fortress.

Operational Status of B-17G 44-8543 (Ye Olde Pub)

Erickson’s own B-17G, serial 44-8543, which currently flies in the markings of B-17F Ye Olde Pub, is fully airworthy and recently completed crew refresher training. The aircraft is scheduled for several airshow appearances across the Pacific Northwest this summer. Detailed inspections, including wing spar and attach fittings, were performed several years ago while the aircraft was disassembled, and it remains in full compliance with all relevant FAA ADs.

Acknowledgments Special thanks to Jim Martinelli, and the team at Erickson Aircraft Collection for sharing these detailed updates and for their ongoing commitment to preserving aviation history. Many thanks indeed to Scott A. Thompson from Aero Vintage Books for allowing us to reproduce this article… his book, Final Cut: The Post-War B-17 Flying Fortress and Survivors as well as other titles are the gold standard when it comes to the airframe history it describes!

My dad was a crew cheif on the P47 and P51 (5th Air Force)in the Phillipiines in WW2 and hIs brother was a crew chief (7th Air Forse) on a b17 in the Phillipines. He was sent to Florida to set up the 4th B29 to bomb Japan, but trainlng was called off because the 3rd a bomb ended the war.. Those two warriors sure had some stories to tell at family gatherings. Sure do miss them and their stories. Have many war time photos of my father and onky one of my Uncles planes.