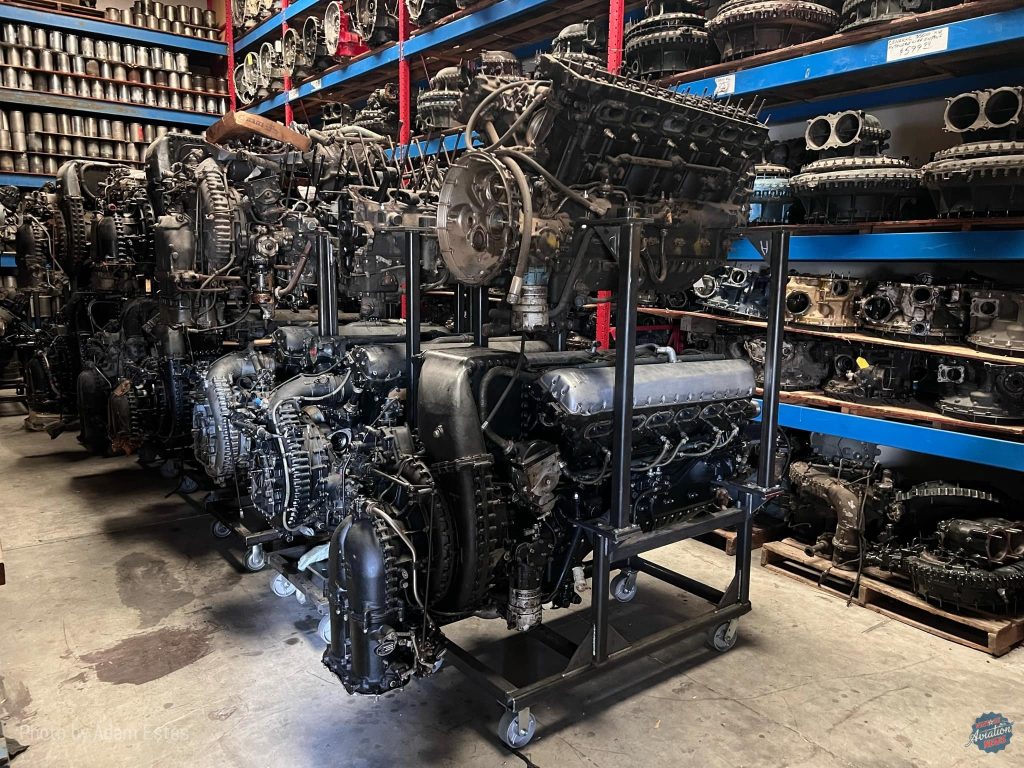

For more than four decades, Vintage V12s has been a leading name in the restoration and overhaul of iconic aircraft engines. In a recent conversation with Jose Flores, the owner of the thriving company, it’s clear that Vintage V12s continues to flourish, despite the challenges of the aviation industry. From an increase in engine overhauls to expanding the team and infrastructure, Vintage V12s’ commitment to excellence in engine maintenance has only strengthened in the last five years.

A Growing Legacy of Engine Overhauls

Since our last article in 2019 (Article HERE), Vintage V12s has made incredible strides, with the number of overhauled engines now reaching 578 and 518 engines repaired. This growth is a testament to the company’s attention to detail and expertise, as well as the ever-expanding demand for vintage engine restoration. “Our operations are now doing about 18 to 20 engines a year,” Jose shared, highlighting the growing workload. “And we have about 18 employees, not including myself.”

This increase in production has not gone unnoticed, with Vintage V12s steadily expanding. The company is in the process of constructing a 10,000-square-foot facility for added storage and resources. A recent acquisition of 45 Allison engines and various critical parts such as cranks and bearings underscores Vintage V12s’ commitment to maintaining a steady inventory for future projects.

Fostering the Next Generation of Aviation Mechanics

One of the highlights of Vintage V12s’ recent success is the inclusion of younger talent in the workforce. Jose mentioned that new employees in their early 20s have been integral in helping the company maintain a steady pace of operations. “We’ve got a lot of new youngsters coming in. They’re coming in at 22, 24, and 26 years old, and they seem to like it,” he said. With an emphasis on hands-on experience, this new generation of mechanics is learning the ropes from veterans like Jose and Jonathan, ensuring the company’s future success. “My son is finishing up school and working full-time here now. He and Jonathan are going to be the ones keeping this going,” Jose explained. This seamless passing of knowledge between generations will help ensure that Vintage V12s remains a leader in the industry for years to come.

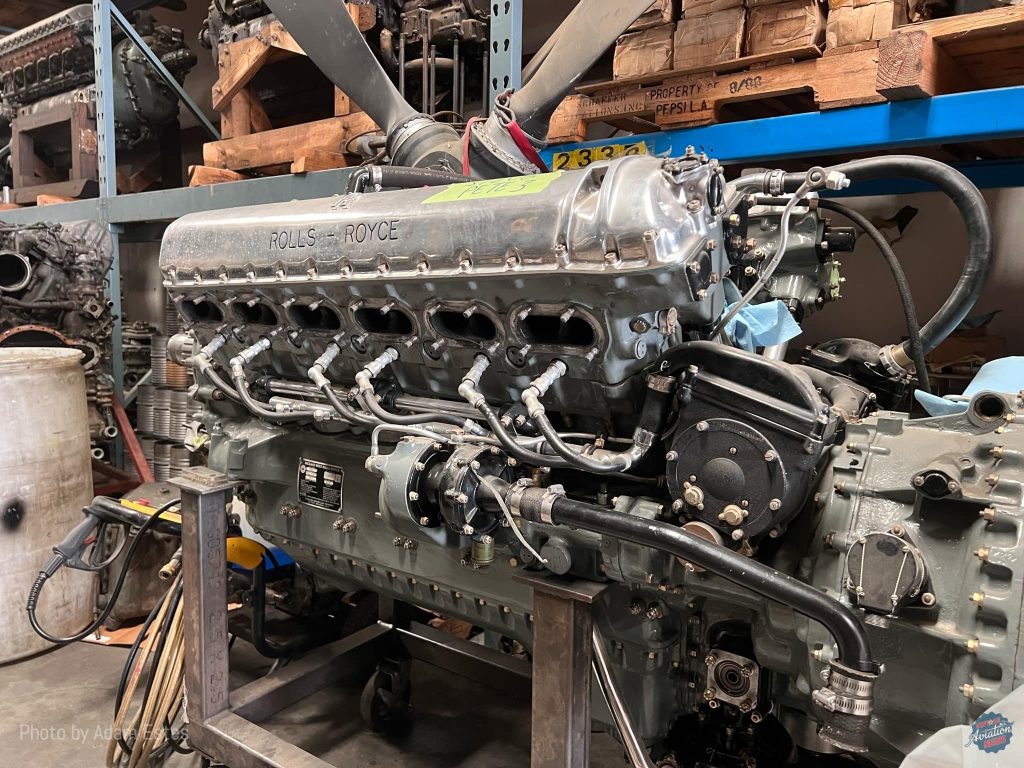

Best Practices for Operating Rolls-Royce Engines

As a company focused on both restoring and maintaining vintage engines, Vintage V12s places high importance on education and best practices for aircraft owners. When asked about the best ways to maintain Rolls-Royce engines, Jose emphasized the importance of proper fuel management.

“One of the biggest mistakes I see is people trying to save a bit of fuel by using the auto lean setting,” Jose explained. “They end up causing more damage than they would if they just kept it on auto-rich.” Maintaining engines in their optimal conditions is vital for longevity. According to Jose, regular checks, especially at intervals of 25 hours, should include valve adjustments and head torquing to keep the engine in top form. For those operating engines less frequently, he stressed the importance of regular use. Engines that sit idle for extended periods are at risk of developing internal corrosion and rust, which can lead to catastrophic engine failure. “When engines sit, moisture builds up, and rust becomes grit. Grit gets into the oil system and damages the engine,” he explained. It’s essential, he noted, that these engines be flown regularly to prevent such issues from developing.

Big Projects and Global Reach

Looking ahead, Vintage V12s continues to take on exciting projects, with notable restorations in progress. “We’re doing a couple of P-38 engines right now—one is still being restored, and another one has been flying and needs engine work,” Jose shared. Vintage V12s is also preparing to finish engines for a Mosquito coming out of New Zealand and working on several Spitfires and Hurricanes. The company remains heavily involved in Mustang restorations and continues to service Allison engines.

“We’re doing about six or seven Allison engines a year and the rest are Merlins, with maybe one Griffon every other year,” Jose said, reflecting on the busy schedule that keeps his team on their toes. Vintage V12s’ reputation has spread far beyond their California base, with clients across the globe. The company recently restored a Spitfire for a customer in India and is currently working on a Mustang for an owner in Israel. A recent engine overhaul for a South African client only further underscores Vintage V12s’ international presence.

The Road Ahead

As the company moves forward, there is no slowing down. With an expanding team, increasing projects, and an ever-growing reputation for precision and quality, Vintage V12s’ future looks brighter than ever. Whether it’s completing historic aircraft restorations or ensuring the continued flight of these aviation icons, Vintage V12s is proud to keep these engines—and the legacy of warbirds—flying for generations to come.

As Jose reflected on the success of the company, he noted, “We’re still moving. The customer base is changing a little bit, but people are more aware of the kind of maintenance these airplanes need. A lot of airplanes are moving around, and we’re keeping them in the air.” Vintage V12s’ legacy of craftsmanship and passion for aviation continues to thrive, ensuring the stories of these incredible machines will be told for decades. For more on Vintage V12s’ work and ongoing projects, check out this article on their engines: The New Vintage V12’s 500 Engines and Beyond.