WarbirdsNews has just received the May/June, 2019 report from Chuck Cravens concerning the restoration of the Dakota Territory Air Museum’s P-47D Thunderbolt 42-27609 at AirCorps Aviation in Bemidji, Minnesota. We thought our readers would be very interested to see how the project has progressed since our last article on this important project. So without further ado, here it goes!

Update

The fuselage extension, cockpit enclosure, and wings were the centers of activity in the restoration shop this month. We will also look into Republic Aviation and Evansville, Indiana’s part in the Arsenal of Democracy.

Fuselage Extension Assembly

Intercooler Exit Door Controls

Cockpit Enclosure

Wings

Republic Aviation Corporation and Evansville, Indiana – Big Contributors to the Arsenal of Democracy

The ongoing planning for next spring’s Arsenal of Democracy Flyover, celebrating the 75th anniversary of VE Day, suggests that a brief history of Republic Aviation Corporation’s part in the famed arsenal is a timely subject.

The Arsenal of Democracy term was first used by President Franklin Delano Roosevelt in a 1940 radio broadcast to describe the need for production efforts to aid Great Britain to defeat the Axis Powers.

After the United States entered the war, the Arsenal of Democracy term expanded to signify the massive unified effort that men, women, manufacturers and the military forces accomplished to produce and employ the tools of war.

Again in FDR’s words, a month after Pearl Harbor, “Powerful enemies must be out-fought and out-produced, It is not enough to turn out just a few more planes, a few more tanks, a few more guns, a few more ships than can be turned out by our enemies,” he said. “We must out-produce them overwhelmingly, so that there can be no question of our ability to provide a crushing superiority of equipment in any theatre of the world war.”

The ramp-up in manufacturing was extraordinary, and every element of American society played its part.

Figures that illustrate the production increases in the aviation sector include growth in production from 6,000 aircraft in entirety of 1939 to a peak of 9,000 in the single month of March 1944.

The United States built more planes in 1944 than the Japanese did from 1939 to 1945!

Republic Aviation was a major part of the expansion of production that made victory a reality.

The first P-47s reached England in late December 1942. There were 88 of the big fighters shipped to the 8th Air Force. These were P-47Cs produced at Republic Aviation’s factory in Farmingdale, New York. It was March 10, 1943 before the 4th Fighter Group conducted America’s first operational fighter sweep in Europe (with 14 P-47Cs). [Ref. Roger Freeman, Thunderbolt, a Documentary History of the Republic P-47, New York: Charles Scribner’s Sons, 1979, p 31]

By February 1943, the P-47D variant was now in production. Republic had foreseen major demand for the Thunderbolt, and broke ground for another factory in Evansville, Indiana on April 11, 1942 to keep pace. By that September, the first Evansville P-47 flew. In total, 15,579 P-47s would be built, more than any other USAAF fighter. They equipped 40 percent of American fighter groups overseas in 1944 and 1945.

Aircraft factories became more efficient, and engineering changes streamlined production as the war went on. Harold Morgan’s book Home Front Warriors mentions several interesting figures on production costs and man hours [Ref. Harold B. Morgan Homefront Warriors, Mount Vernon, IN Harold B. Morgan, 2011, p.4].

The early D models built in Evansville each required 22,927 man hours, and cost $69,750. By September of 1944, man hours were reduced to 6,290 and cost to $45,600.

Design changes were a large part of the cost reductions.

They included:

- Elimination of an instrument panel light

- Redesigning landing gear down stops

- Wing de-icing equipment eliminated

- Tail wheel steering eliminated (P-47Bs, the first 57 P-47Cs, and RP-47B and Cs had tail wheel steering cables and levers, and the Ds and subsequent models did not)

- Tail wheel position indicator in cockpit eliminated

- Propane priming system eliminated

- Painting eliminated

- Equalizing system on wing flaps eliminated

- Redesign to the landing gear box fittings

- Propellor de-icing provisions eliminated

- Cockpit defrosting and ventilating tubes redesigned in plastic

- Heat provided by the engine eliminated windshield icing

- A lower windshield panel eliminated

- Carburetor air heating provisions eliminated

- Adoption of bubble canopy reduced cost and manufacturing time

- The primary reduction in man hours was accomplished by manufacturing on powered conveyor lines [Ref. Harold B. Morgan Homefront Warriors, Mount Vernon, IN Harold B. Morgan, 2011, p.4]

Some Major P-47 Subcontractors:

Republic and all the other major aircraft manufacturers depended on subcontractors to support the massive production effort that was needed during the war. Many of these subcontractors had produced consumer goods before the war and needed to completely change their production lines over to aircraft parts and/or assembly.

A few of the more important subcontractors for the Evansville Republic plant were:

• Firestone Tire & Rubber: self sealing fuel tanks, tires, engine oil seal “O” rings

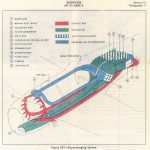

• Servel Corporation: (pre-war manufacturer of heating and cooling appliances) – almost all P-47 wings for Evansville plant

• Hoosier Cardinal (an Evansville stamping company that made metal refrigerator parts, including ice cube trays, and lamps): tail surface sections

• General Electric: Turbocharger

• Pratt & Whitney: R-2800-59 engine

Evansville, Indiana had many more contributions to the Arsenal of Democracy. Parts and subassemblies for the F4F Wildcat, F4U Corsair, PBY Catalina, B-29 Superfortress, and others were built in Evansville. The major non-aviation related product built in Evansville involved the construction of 167 LST (Landing Ship Tank) naval vessels produced at the Missouri Valley Bridge and Iron Company shipyard.

Chrysler’s Evansville Plymouth Automobile plant converted to the production of .45 semi-automatic sidearm cartridges, and they also rebuilt 1,600 Sherman tanks, and 4,000 military trucks. Chrysler’s Evansville arsenal produced over 3.2 billion .45 caliber ACP cartridges, 96% of the US wartime production in that caliber.

Evansville also sewed uniforms, and supplied components of plastic, wood, and metal for weaponry, combat vehicles, and long-range bombers.

In fact, during World War II, Evansville became the most productive war materials manufacturing city per capita in the world. [Ref. Reghan Wetzel,Communication Intern, University of Southern Indiana’s Center for Applied Research and Economic Development (CARED), Freedom Heritage Museum write up, downloaded 6-13-2019 ]

And that’s all for this month. We wish to thank AirCorps Aviation, Chuck Cravens (words and images) as well as John LaTourelle (images) for making this report possible! We look forwards to bringing more restoration reports on progress with this rare machine in the coming months.

Is the P-47 Thunderbolt your favorite airplane? Make sure to purchase issue #73 of Warbird Digest featuring the beautiful “Dottie Mae”