It’s that time again, and we have another of our monthly updates from Tom Reilly about his intrepid team’s efforts in restoring the sole surviving XP-82 Twin Mustang. Tom Reilly is a master craftsman, and the quality of the workmanship going into this project is clear for all to see. This update is based upon Tom’s words.

Wings

Paul and Randall have completed the final back-drilling of all four top wing skins and riveted all of the ribs to the spars. Weezie and Paiden (the new guy) are finishing up riveting doublers (all 64 of them) on the top of each hat channel assembly located in the wing fuel tank bays.

Ayman, Jeremy, Tim and a part-time volunteer, Josh, have pre-drilled all the stringers, ribs, bulkheads and spar caps for the left outer wing panel, a mirror image of their work on the right wing a couple of months ago. Very soon Paul and Randall will complete the final small tasks in the right wing prior to mounting it in the fixture, and they will then switch over to the left wing. Following that, Ayman and Tim will complete the coolant exit doors and fuselage ducting.

Time is getting closer for both outer wings to come off the center section and go into the permanent wing fixture for final drilling and riveting. Tom and his team will then rotate the Twin Mustang 90˚ to the right so they can begin attaching both aft fuselage extensions and the horizontal stabilizer.

English Wheel Parts

Casey Hill, English Wheel parts maker extraordinaire, completed two under canopy aft fuselage skins. They look magnificent!

Systems (Canopies and Coolant Tubes)

Weezie and Tom have completed both cockpit emergency canopy jettison systems. There must be a mile of cables and pulleys for both of those systems to work, and precise set-up measurements must be followed to assure that each canopy truck releases simultaneously. Tim has completed the final tightening and clamping of all forward coolant tubing in both cockpits.

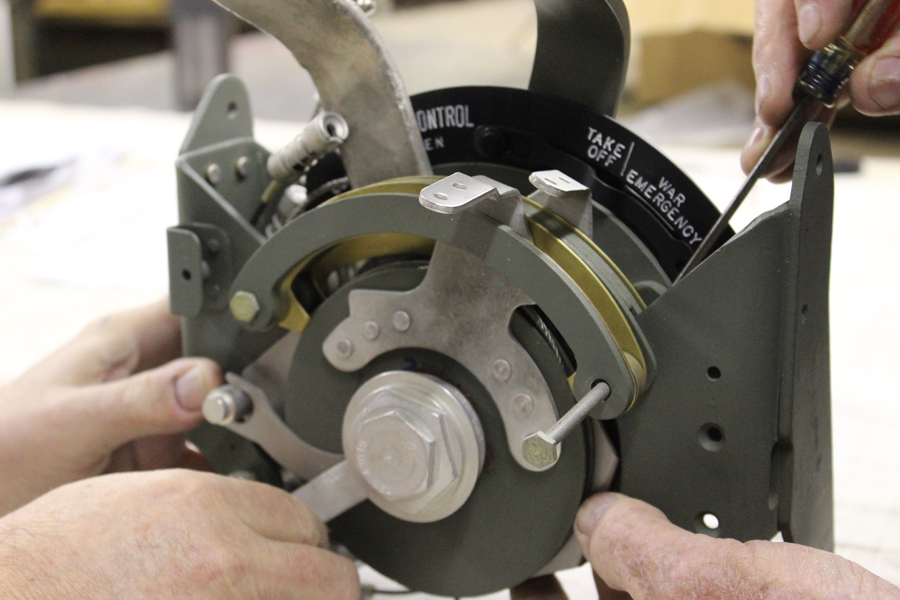

Right-hand Throttle Quadrant

Ken Friend (volunteer), Weezie and Tom completed the right-hand throttle quadrant.

During the Alaska crash recovery in 2008, Tom stumbled over the fire-damaged remains of the right-hand quadrant. Most of the aluminum parts were burned beyond recognition, but the key steel parts, arms, bushings and shafts survived. There are many changes between the right-hand and left-hand quadrants due to the different locations and through-firewall holes for the throttle and prop control rods. During the recovery, Tom looked at the throttle quadrant and made the decision that it was too damaged to load into the basket, but then had second thoughts a day later. He’s very grateful he decided to take it as some of these steel parts would have been very time consuming to duplicate. The team performed Rockwell testing on the hardness of the steel parts to determine that the fire had not permanently damaged them, and they all passed.

Machine Shops

One of the projects four sub-contract machine shops has been making magnificent progress on all of the remaining large and small parts that needed to complete the XP-82 project. There are still quite a number to finish, but the list is getting shorter each day. Some of the key parts that were completed last month were the heat exchanger end caps, mounting rings, seat rail mounts and flap arms (that were pictured in last month’s news release). With these parts completed, Martin Radiator is making good progress on our two heat exchangers.

Weezie, Tim and Tom have been installing the remaining countless small parts in the fuselages and center section that have been detailed and packed away for months in the storage container.

Bumps in the Road – Firewall Dishpans

The dishpan is a stainless pan similar to a small kitchen sink that mounts the oil tank into the steel firewall.

The project had the two original XP-82 dishpans, one perfect and one severely damaged and an E model one that came with the Colorado parts find that was identical except for 2” in vertical height. After Tom started making a modification to add these two vertical inches, he realized that when the instrument panel cover was off, the welded modification would be obvious and he felt that was unacceptable. So Tom decided to press a new one. It’s a very difficult job, but it can be done with a bit of care and skill.

That’s all for this month, and we must thank Tom very much for his update!

This article is based on the XP-82 Restoration Project January Newsletter and is reproduced here with the permission of Tom Reilly. Visit the XP-82 Restoration Project’s website for more information.