It has been some time since our last update on the MAPS Air Museum‘s FG-1D Corsair restoration. Located in Akron, Ohio, the museum had been pursuing a Goodyear-built Corsair for several years before finally acquiring a partial airframe for display. This particular aircraft is the remnants of FG-1D BuNo. 76671, which had been part of Goodyear’s “World of Rubber” museum in Akron for over fifty years until its closure in August 2009. Our previous article tells the full story of this airplane.

Dave Pawski, a volunteer at the MAPS Museum and the restoration lead on the FG-1D Corsair, has been overseeing the aircraft’s ongoing restoration with a focus on both historical accuracy and functionality. As a mechanical engineer, Dave handles all the engineering work, drawing on resources like microfilms, the AirCorps Library, and 3D modeling software SOLIDWORKS to recreate and verify components from the original drawings.

Since the beginning of 2025, significant progress has been made. Early in the year, the team completed skinning the two center flaps and began preparing the rudder and elevator for covering. They are using a locally sourced water-based system, which is safer and more forgiving than traditional poly-fiber methods. The fabric is now glued, shrunk, and nearly finished with taping. The next steps involve applying “Becco fill” for UV protection, followed by three crosscoats and a topcoat, with completion expected before winter.

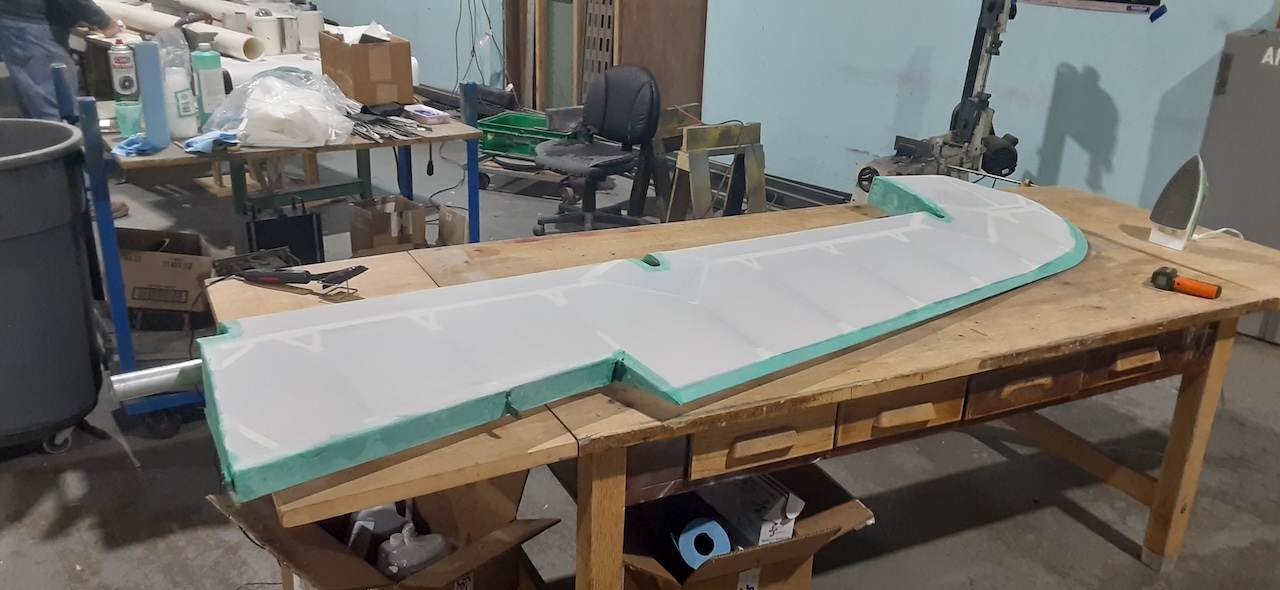

In addition to the control surfaces, Dave designed and built a steel fixture for the wing leading edges to ensure proper alignment and visual accuracy. Rib stations are being fitted, with minor adjustments required to achieve precise shaping. The tail and main landing gear have been installed, though the right main gear is still undergoing repairs due to damaged components. Donated parts allowed assembly of the left gear, while replacement sections are being used to reconstruct the right gear.

Dave also engineered an air-cylinder system to operate the flaps, allowing smooth movement without hydraulics. Early testing has been successful, and a demonstration was shared on the museum’s social media.

Sourcing authentic parts has been a challenge. After years of searching, the team acquired four wheels through Facebook, mounted them with donated tires, and powder-coated them for a finished look. Chuck Wahl of Vultures Row Aviation also generously donated various parts, including static restoration components, leading edge skins, flap brackets, and a set of wooden ailerons built after the prototype stage.

Looking ahead, the team’s primary goal is to have the Corsair sitting on its wheels before Ohio’s winter sets in. Once that milestone is reached, the outer wings will be built in the restoration shop, and the aircraft will eventually move to the hangar. Dave has already designed the wing fold mechanism, which will function as intended, maintaining both authenticity and practicality. The restoration represents a meticulous combination of historical research, engineering expertise, and community collaboration, bringing the FG-1D Corsair ever closer to display-ready condition. Anyone wishing to help contribute to this worthy project, or another project at the MAPS Air Museum, should click HERE to find out how to help.

Noticed a bit of a type on the covering. I do Tech Support for Stewart Systems; the fabric system being used on the restoration. The term “Becco fill” was used mid way in the article. The correct term is EkoFill. EkoFill provides the Ultra Violet (UV) protection over the fabric to prevent fabric degradation over time. I’m glad to see the use of our system on this historic restoration.