From an original update by Chuck Cravens

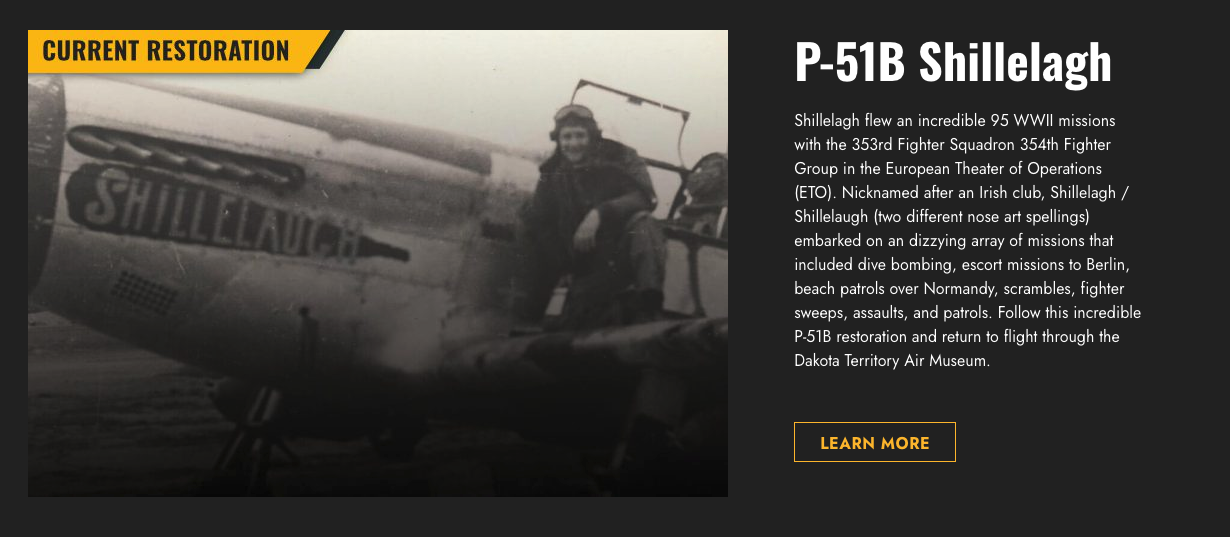

AirCorps Aviation, based in Bemidji, Minnesota, continues to demonstrate its expertise in high-quality aircraft restoration with several major projects underway. Among the most notable is the P-51B Mustang “Shillelagh,” a rare and historically significant aircraft currently being restored for the Dakota Territory Air Museum. Updates provided by Chuck Cravens highlight the ongoing craftsmanship and technical precision being applied to this iconic fighter.

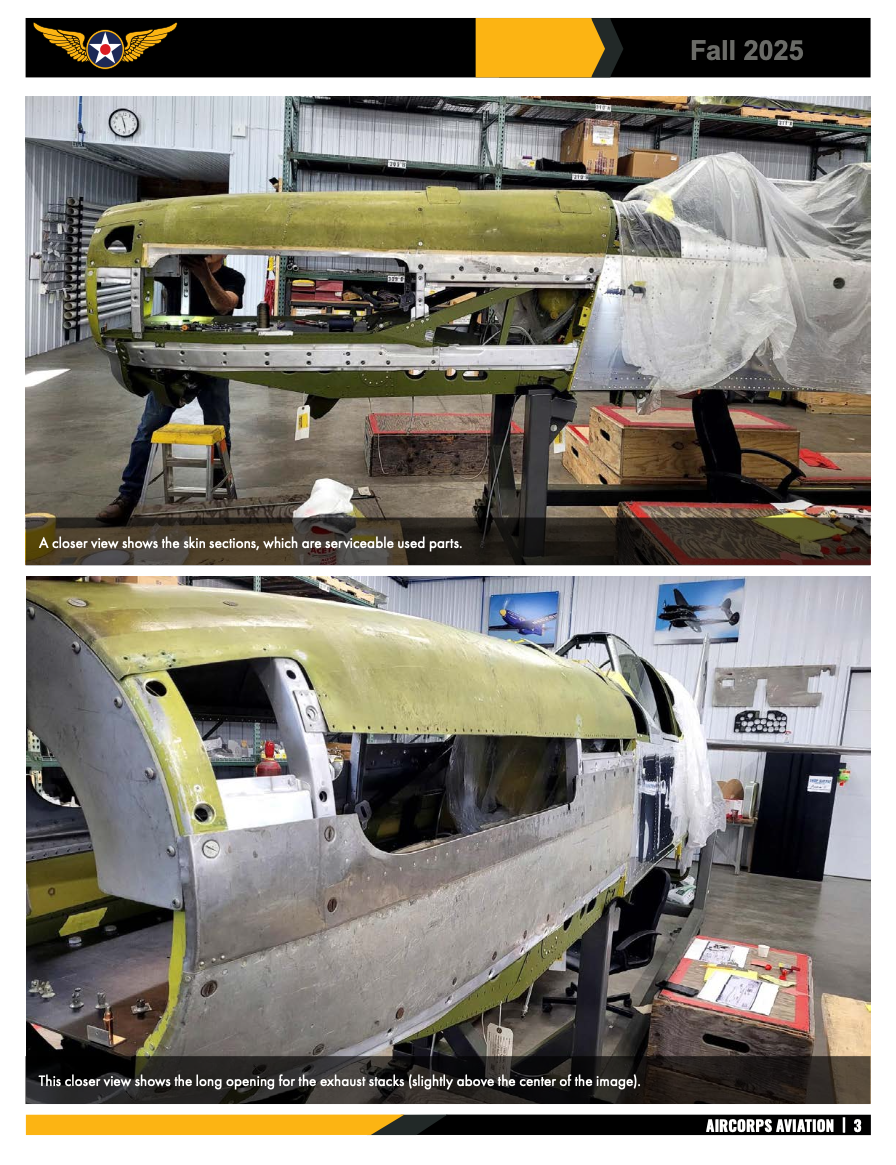

In recent months, the AirCorps team has made significant progress on both the fuselage and wing structures. After completing much of the internal fuselage surface control systems, attention shifted to the firewall-forward section, where the forward frames supporting the cowl, nose ring, and characteristic “smile” of the Mustang were installed. Once these structural elements were in place, work began on fitting the cowl skins, a critical step in restoring the aircraft’s forward fuselage to authentic specifications.

Wing assembly also advanced, with additional skin sections permanently riveted in place. This meticulous process, involving thousands of individual rivets, ensures both structural integrity and historical accuracy. The installation of tank cover doors, located beneath the fuel tanks for maintenance access, was prepared as part of the ongoing assembly. AirCorps Aviation’s expansion into contract manufacturing for the broader aerospace industry has brought advanced capabilities to the restoration process, including the addition of a large-scale 3D printer. This technology enables rapid prototyping, precise verification, and accurate fit-checking of complex components such as the clamshell landing gear doors (P/N 73-33301) before fabrication. Using CAD-based models, the printed sections are assembled to create full-scale prototypes, allowing the restoration team to refine every detail prior to final production.

ready for installation (Bottom Left). The new engine is a Packard-built Rolls-Royce V-1650-7 Merlin (Bottom Right).

The combination of traditional craftsmanship and modern engineering tools ensures that “Shillelagh III” will meet the exacting standards expected by collectors, historians, and aviation enthusiasts alike. With each step, AirCorps Aviation brings this P-51B Mustang closer to a fully restored, airworthy condition, preserving an important piece of aviation history for future generations. For more information about AirCorps Aviation and to follow their restorations, visit www.aircorpsaviation.com.

![Catch-22 Star North American B-25 Mitchell Restoration Continues in Belgium 23 TB-25N 44-30925 in the Belgian Aircraft Preservation Association’s workshop at Gembloux. [Photo courtesy BAPA]](https://vintageaviationnews.com/wp-content/uploads/BAPA-B-25-20230312.jpg)