In Brisbane, Queensland, the meticulous restoration of Bristol Hercules engines for Beaufighter projects is making steady progress. The work is led by Peter Brooke, supported by Robert Greinert, whose company, Historical Aircraft Engines, provides an ideal workshop environment for such delicate and precise work. Since our previous coverage in 2018, interest in this restoration has remained strong, and our October 2025 visit revealed significant advancements.

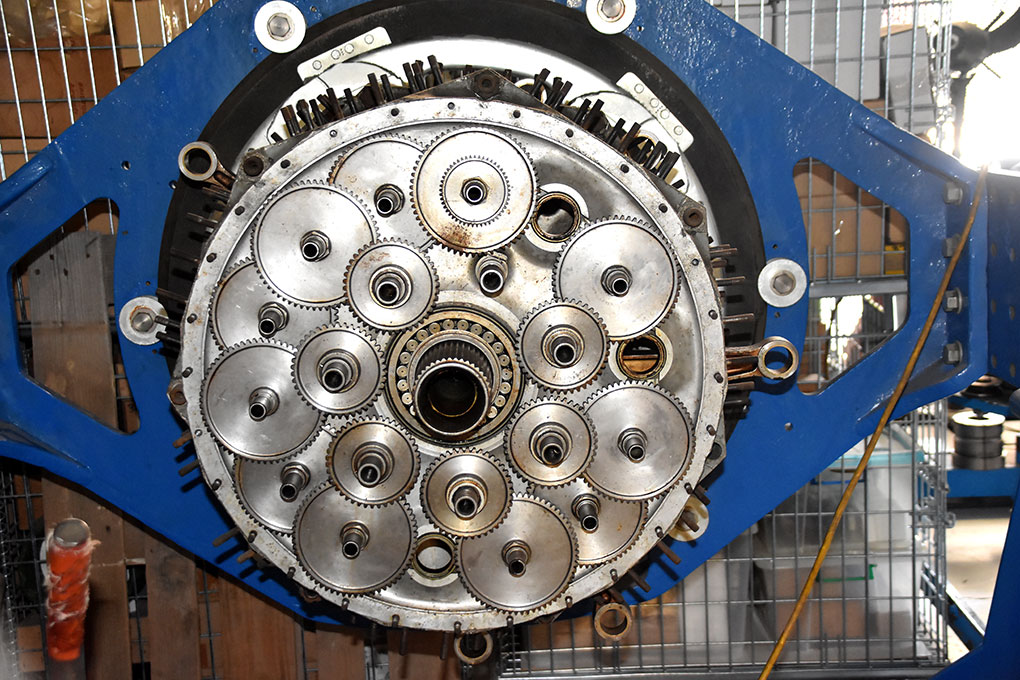

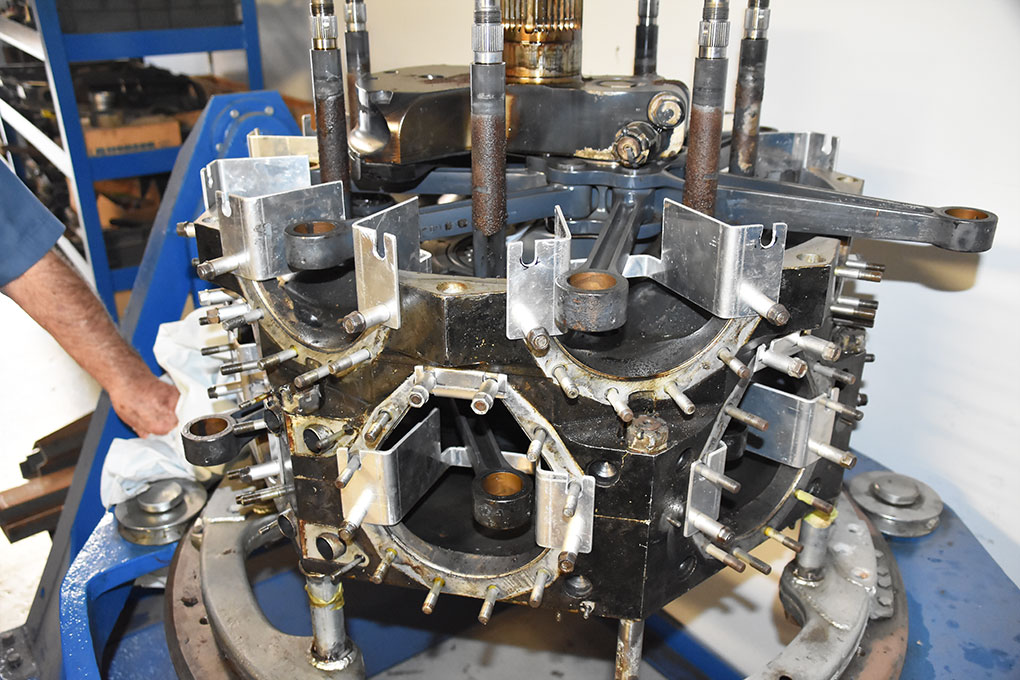

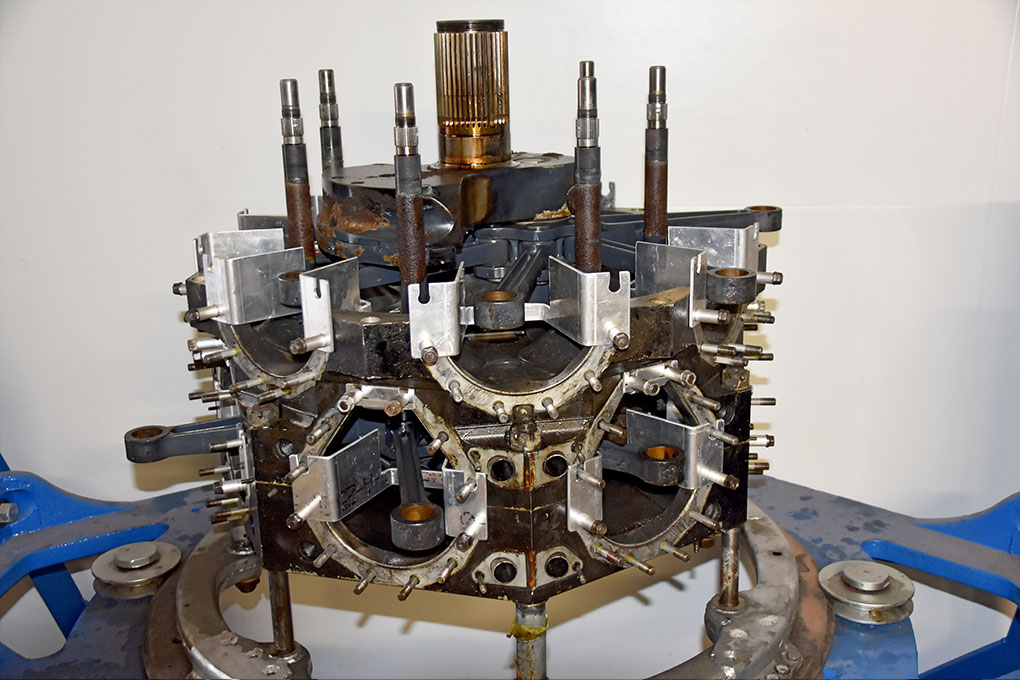

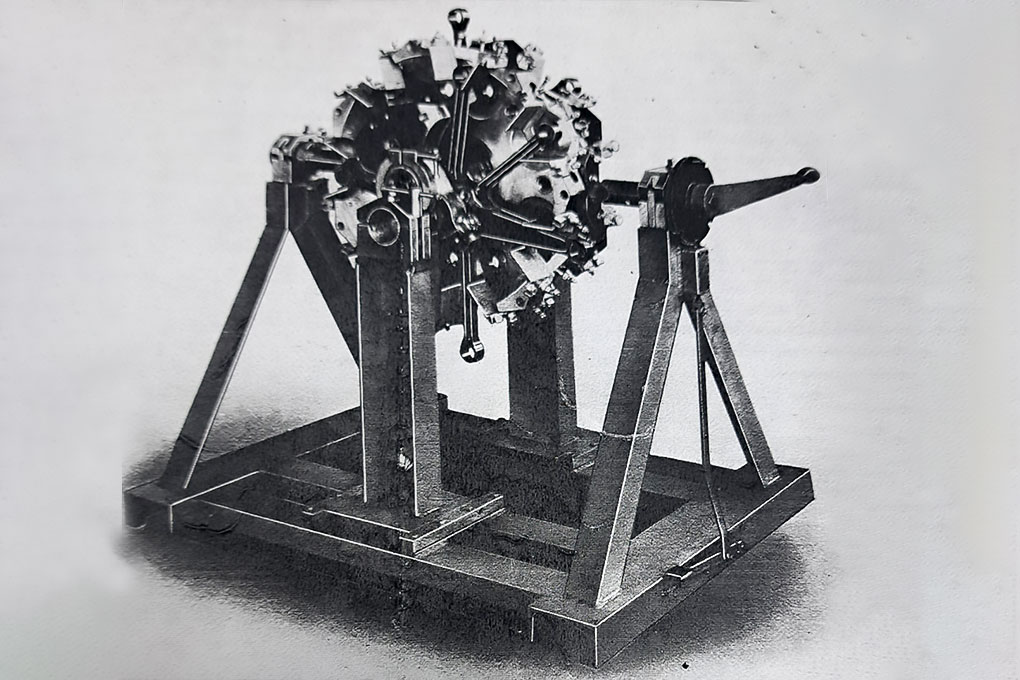

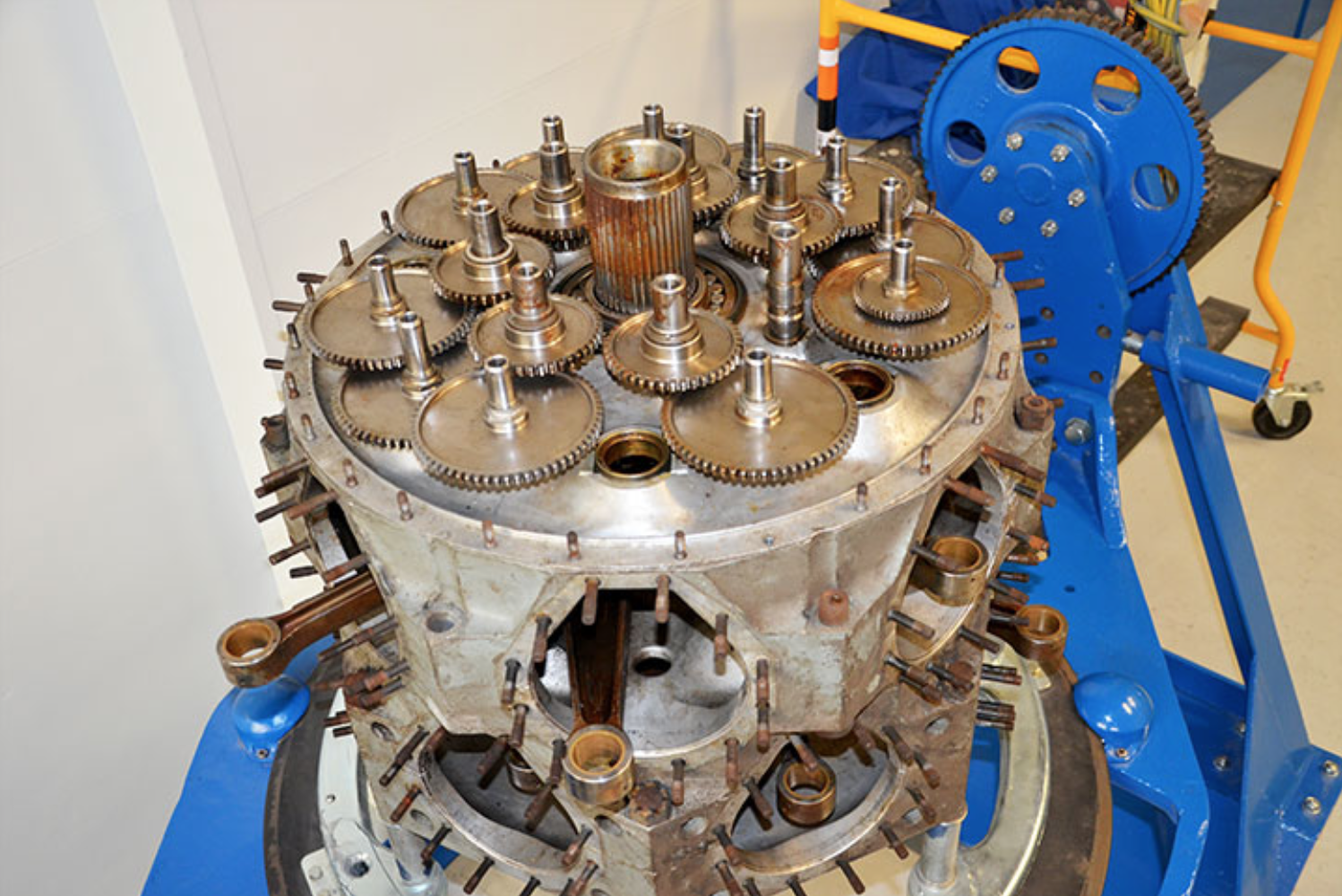

Several Hercules engines had already been disassembled and evaluated before the restoration program officially began. The current effort follows a carefully structured plan, focusing on the intricate reassembly of these unique sleeve-valve engines. A major technical hurdle has been the creation of an assembly and alignment stand capable of holding the Hercules’ three-piece crankcase in perfect alignment during reassembly. Even slight distortions could prevent the crankshaft and internal components from fitting correctly. To address this, Peter is designing a custom jig and stand while seeking original wartime drawings or surviving examples from Bristol or historic service depots. Anyone in the vintage aviation community who can provide such resources is encouraged to reach out, as this information is crucial to the project’s success.

While the assembly stand is under construction, Peter is cataloging, cleaning, and organizing the extensive inventory of Hercules parts. The plan currently includes the full restoration of at least three engines, with the possibility of extending to five if additional usable parts can be sourced. Several donor engines and major subassemblies have already been secured, giving the team a strong starting point. The goal is ambitious yet realistic: the first restored Hercules engine could be operational within 18 to 24 months. Collectors and restorers with spare Hercules components are encouraged to contribute, as every part helps preserve these historic powerplants.

During our visit, the workshop was also busy with other restoration efforts, including World War II Japanese aircraft engines being prepared for static display. Many of these engines are privately owned, with Peter overseeing their careful reconstruction using a combination of historic techniques and modern methods. The Historical Aircraft Engines facility is exceptionally well-equipped for high-precision work. As Robert Greinert explained, “Our workshop is designed to meet the tight tolerances required for rare radial engines. With Peter’s skill, we can tackle even the most complex rebuilds confidently.”

Many engines arrive in poor condition, yet restoration to museum-quality standards is achievable. For components that are missing or damaged beyond repair, the team uses 3D printing, CNC machining, and traditional pattern-making techniques to recreate parts to original specifications. This combination of old and new ensures each engine remains true to its wartime design.

The Hercules restoration at Historical Aircraft Engines represents one of the most ambitious efforts in recent years to return these iconic engines to life. Once operational, these powerplants will again bring the Bristol Beaufighter and other historic aircraft to life, paying tribute to the engineers and crews who relied on them. Our thanks to Peter Brooke and Robert Greinert for sharing their time and expertise. We will continue to track this restoration as it moves closer to the day when the roar of a running Bristol Hercules can be heard once more.

Is this engine the “Swiss watch” of engines ? Loads of gears. Mike Trotter Woodstock ONT