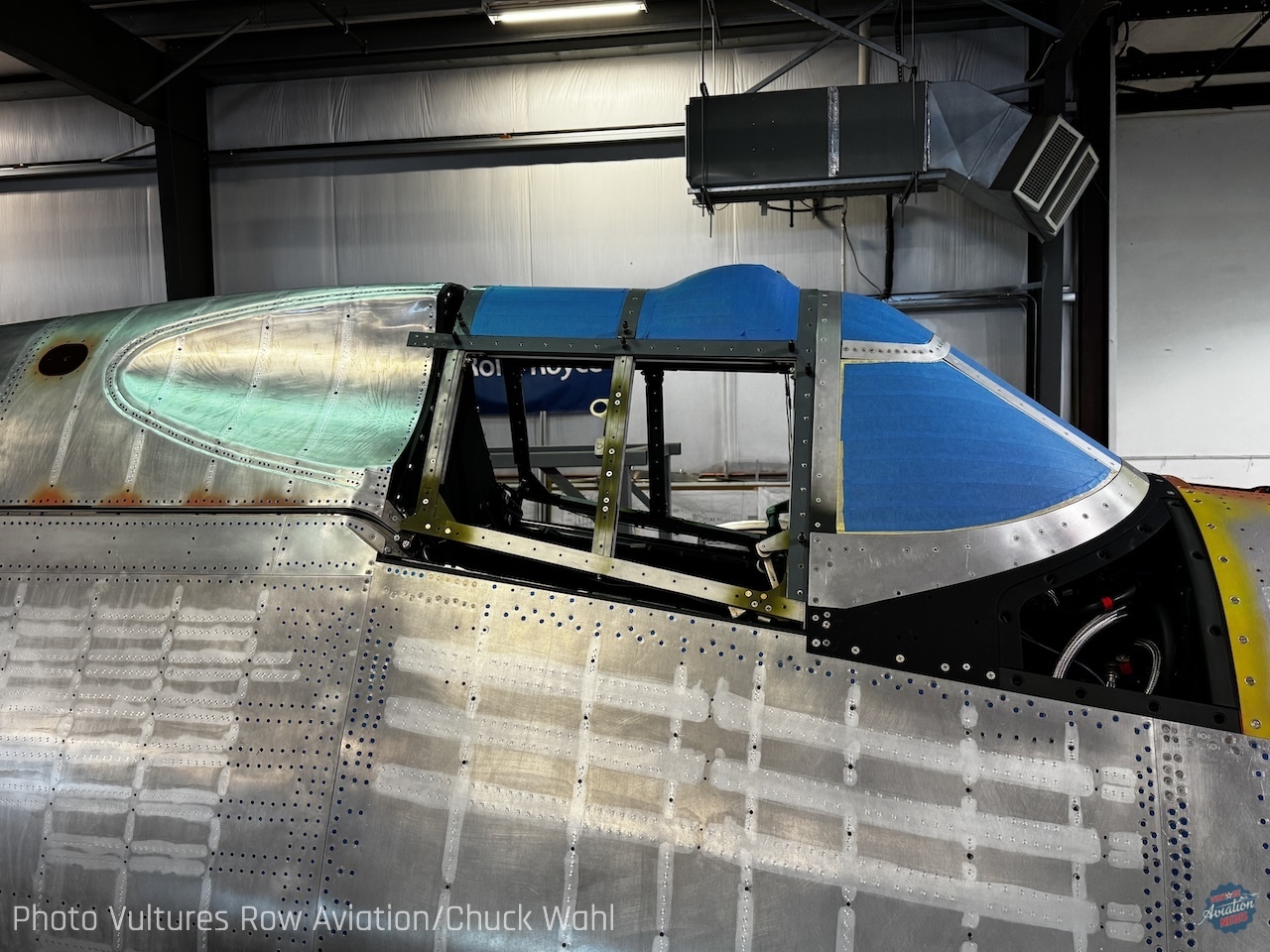

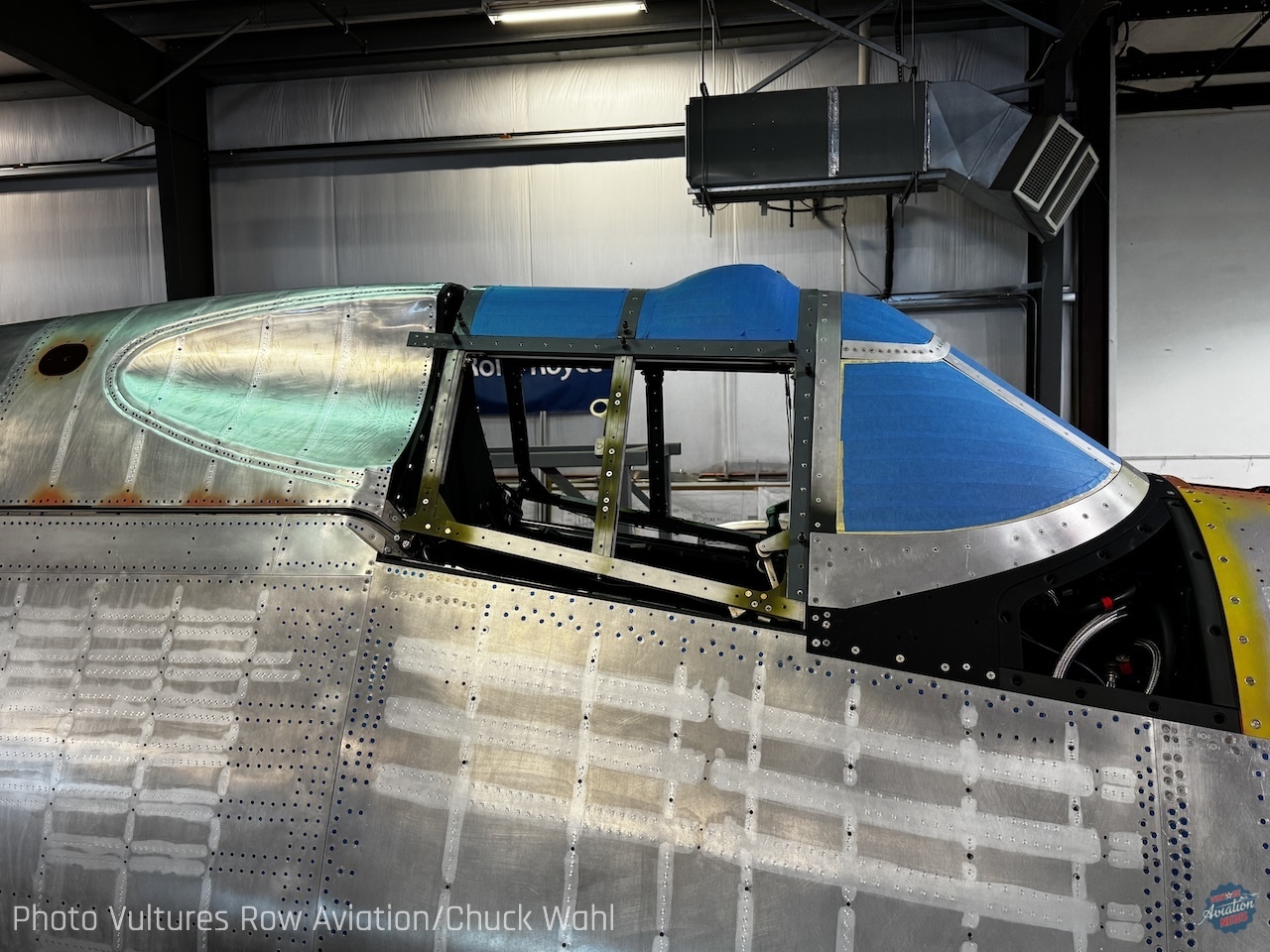

Vultures Row Aviation, the “Corsair Factory” led by restorer Chuck Wahl, notched two major milestones this week on the Vought-Sikorsky F4U-1 Corsair (BuNo 02449), an early and rare “birdcage” variant. The team successfully joined the aft fuselage to the cockpit at the factory production break and test-fit the birdcage canopy—key steps that visually and structurally transform the project. Speaking with Vintage Aviation News, Wahl outlined the progress in detail.

Seamless join at Station 186, 92 bolts, and a perfect canopy fit

“I’ve been concentrating on the mid section and aft section for the birdcage since early this year and completed all the wiring, all the hydraulics, and all the miscellaneous things that go into it—the cables, the trim cables, pulleys—everything is done,” Wahl said. “We recently joined the tail section to the cockpit at the production break, which is station 186. Surprisingly enough, it all went together with zero issues and all the bolt-pattern holes lined up perfectly. There are 92 bolts that hold the section together.”

“Just yesterday we test-fit the canopy. The birdcage canopy was test-fit to the cockpit section for the first time with the tail section in place. The reason that’s significant is the tail section has the canopy’s rear tracks built into it. We have two canopy roller tracks that roll in the midsection behind station 186, and the two forward canopy tracks run in the cockpit.”

“The canopy rolls open and closed, hits all the locks, no issues. What really excited us was that when the canopy comes together at the original windscreen, it’s a perfect fit all the way around. The front windscreen on our airplane is the original one from this airplane, recovered in the jungle when the airframe was found. It’s pretty special to know you’re looking through the same windscreen pilots used in 1943.”

Control surfaces complete; tail fairings and landing gear next

“With the airplane now essentially ‘firewall to tail,’ the next phases are the fairings for the horizontals,” Wahl continued. “The vertical and the rudder fairings are going in next. All the control surfaces are already done—we’ve got both horizontals, both elevators, the rudder, and the vertical finished and waiting for fabric on the appropriate surfaces. All six flaps are done, and both ailerons—wood—are done.”

“I’m going to start putting in the main landing gear over the next month or two. The gear is overhauled, painted, and ready for final assembly into the airplane. It’s been in the airplane before and out prior to paint, so we know everything fits. As soon as the tail fairings are on, the tailwheel goes in—along with all the linkages and the mechanism for the tailwheel, tailhook, and tailwheel doors. It’s an elaborate setup, but all of it is overhauled, painted, and ready. It just has to wait until after the fairings; otherwise you can’t get up in there to finish the tail-surface fairings. We’re on target for the airplane to be sitting on three wheels by the end of the year.”

Pivot to the engine by spring; wings advance toward fabric

“At that point I’m going to pivot straight to the engine, which is partially built up on the QEC stand,” Wahl said. “I’ll complete all the accessories and the cables—electrical, fuel, hydraulic—everything that needs finishing. My guesstimate is early 2026 for hanging the engine on the airplane.”

“The outer wings have progressed a lot, with many painted, finished items going in—from the inboard aileron hinge all the way inboard to the wing fold. Both birdcage wings are complete spar-forward. The entire wet section—58 gallons of fuel—spar-forward is 100% complete. All the ammo boxes and structure around the ammo box, the gun bay, and the wing-fold rib are complete with the exception of wiring and cables. The wing-fold tracks are next—starting tomorrow.”

Brief pause to support other projects; wings out of jigs by mid-2026

“The other airplanes’ wings need attention too, so there’ll be a short break from the birdcage wings—probably until October,” Wahl noted. “Then we’ll start on the outer truss ribs where the fabric covers. A conservative estimate is that the wings will be out of the jigs by May or June of next summer—2026—and ready for fabric.”

Flight horizon: two years targeted, three at the outside

“The airplane is progressing in big steps—big items going on and the airframe growing quickly—but there’s still a lot of little stuff to do before flight,” Wahl said. “We’re pushing for flight around summer of 2027. I don’t see how it could possibly go past three unless I just don’t work on it.” Wahl added that he’s also supporting other restorations at Vultures Row Aviation (Click HERE) and offered to discuss those projects in a future update.