As many of our readers will be well aware, Avro Lancaster B.VII NX611 Just Jane is under restoration to airworthy condition with the Lincoln Aviation Heritage Center at former RAF East Kirkby in Lincolnshire, England. While the group has made magnificent progress, even during the pandemic, the recent lockdown for much of the UK has presented significant challenges. Nevertheless, they are indeed moving forwards, and we thought that our readers might like to see a recent report, reproduced here with permission…

The Rivet Club – Newsletter 139

by Andrew Panton

Welcome to Newsletter 139,

A varied week this week as we near the end of the winter servicing period.

John and Gary have stripped down the propeller from number 4 engine. This prop needed a new front seal, as a leak had developed last year. While the prop was apart, it received a full clean and inspection ready for another year of engine runs. With the new seals in place, the team rebuilt the propeller using the prop table and then rehung the unit on NX611 where it is now ready to receive the dome and oil tube.

Brad has been working on NX611’s engine chin cowlings. These cowlings have a manually-controlled system which introduces a radiator intake flap. This sprung flap is designed to reduce the air flow through the radiator in cold climates to enable the engine to warm quickly. These flaps have never been operational for us but, ironically, many Rolls-Royce Merlin operators with other aircraft types struggle to keep their engines cool as opposed to enabling them to get hot quicker! As we only do short runs with the aircraft, the oil struggles to get hot,so we will be experimenting with running the cooler months with the flaps open to get the engines warmer to enable them to burn off any condensation in the oil.

John and Les have been making good progress riveting the top skins onto the static wingtip; John operating the gun and Les using the buck. The main top skins will be riveted while we wait for the lower skins to undergo repainting. As with the airworthy wingtips, the team are waiting for the new trailing edge to arrive from the casting company. The static wingtip will receive its original trailing edge once these are done, as it is currently in use as a pattern for the newly-manufactured examples. Once the trailing edge is back, the team will trial-fit it in the jig to make sure all of the structure is correct, and then the trailing edge skins can be re-riveted back on the static wingtip.

This last week we had our trial day with the dry ice blasting company. We set them the task of removing paint from the formers in the rear fuselage section, concentrating on the port side of the aircraft. The results varied but, it was generally slow progress. The dry ice blasting is a great method for the inside of the aircraft, as it is both gentle on the structure and leaves no blasting media behind. However, it is so gentle that it takes a long time to remove all of the paint. This single day of blasting removed paint from roughly an eighth of the rear fuselage formers, suggesting that it will take three weeks of labor (and £16,000!) to remove the paint for the remaining formers and stringers in that rear section. We are therefore exploring other paint stripping methods, including laser stripping.

We also have another report (below) for the FN82 rear turret restoration

FN82 Turret update March 2021

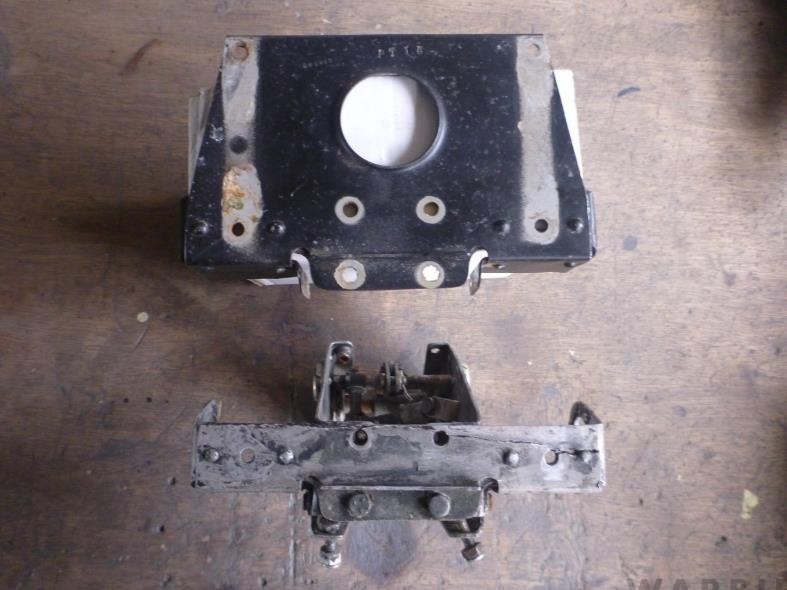

The plan for March was to rebuild the turret control unit. This unit is comprised of three sub- assemblies, these being the control column, the valve box and the rotating service joint. This complex assembly was in poor condition generally and at some stage had suffered damage. Some of the damage had been repaired and several parts were reproductions, made to accommodate this damage. We have a spare turret control unit which also has problems but, in general, it has the parts we need to restore the original unit

The first job here was to strip down both of the units and identify the best components to build one to use on NX611 and a second for display purposes. Once this was complete, we cleaned and then resprayed the better components, as seen below.

That then left the matter of the damaged and/or reproduction parts which need rebuilding for the display turret.

An example of these damaged parts can be seen below. Both items should be identical, but the lower unit is missing roughly the top two thirds of the azimuth controller bracket.

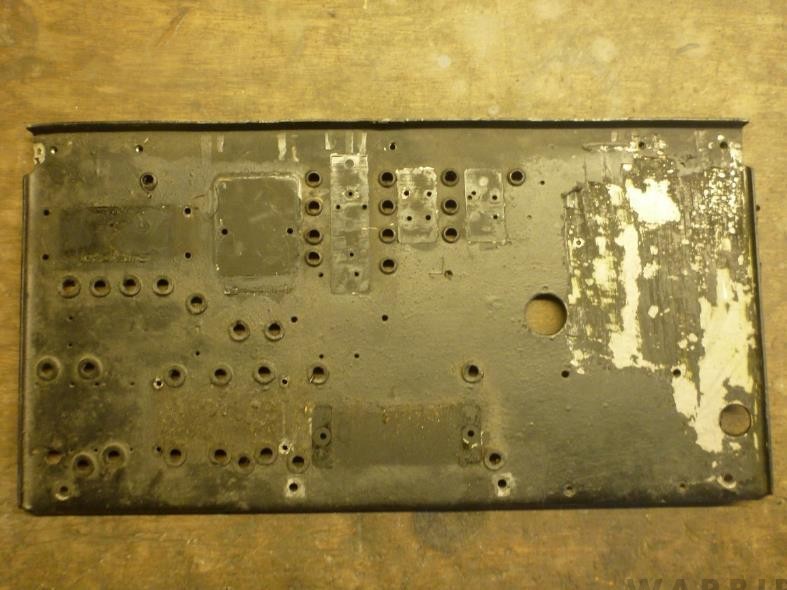

With the turret control units completed as far as possible, there was still time in March to launch into the control panel. Although in reasonable condition, the panel had undergone modifications during its service life. With the panel stripped back, it was now possible to clean and re-spray it, and then identify the components which should be fitted in accordance with the original Air Publications.

Once we located the necessary components, we installed them on the panel and then added the appropriate wiring. While for display purposes only, the wiring is connected to the correct components and then tucked back behind the panel. All that remains left to do with this panel now is to fit the rubber grommets for the cable pass-throughs. With the control panel and turret control unit now complete, it was possible to temporarily install them into the turret as seen below.

The plan for April is to get working on the plethora of hydraulic components and small detail items that connect the turret control unit to the servo feed unit, hydraulic motors and elevation ram. This is going to be a fiddly process, but at least the weather is now getting warmer and the workshop is more comfortable.

Stay safe and thanks for your support!

Andrew Panton

That’s all for this particular update. We hope that you have enjoyed reading it. As can be seen, a lot of work remains to be done, but the aircraft is well on the way back to flying condition. It is being done in a methodical and careful manner in order to keep the aircraft available for ground-running operations during the summer months. For those interested in helping support this important project, please click HERE

Be sure to check out their store HERE as well… There are many cool items to buy which will help get Just Jane back in the air!