As the Vulcan to the Sky Trust focuses on a critical fundraising campaign to safeguard Vulcan XH558 for future generations, the aircraft’s maintenance team continues with essential upkeep of the iconic bomber. Maintenance Director Connor Sykes has provided the latest updates on progress across fuel, hydraulic, engine, and pneumatic systems.

Fuel System Restored The No. 6 starboard fuel pump is now fully operational, restoring complete functionality to XH558’s fuel system. The issue, first reported in earlier newsletters, emerged during routine checks when the pump was found inoperable. Initial attempts to replace the pump revealed that the wiring connector had deteriorated, disconnecting from the loom due to perished wires. The team sourced a brand-new connector with attached wiring from central stores. Each wire was carefully traced, continuity-checked, labelled, and soldered to the correct pins before reattaching the connector to the loom. Functional testing confirmed that the pump was working perfectly, returning full fuel system operation to the aircraft.

Hydraulic Systems Attention also turned to the bomb doors and the Emergency Hydraulic Power Pack (EHPP), which was topped up with Aeroshell 41 hydraulic fluid. Routine system checks revealed that the bomb doors, once opened, tended to creep back toward the closed position—a sign of air trapped in the hydraulic rams. To resolve this, the team used a hydraulic rig to restore full system pressure and work any remaining air out of the rams. This ensures the bomb doors will now remain securely in the open position during operation.

Engines Engine work has continued alongside the fuel and hydraulic maintenance. The freshly serviced Auxiliary Air Pump (AAPP) has been tested on its rig and is functioning correctly. Before refitting to the aircraft, the fire bottle and oxygen bottles—used for high-altitude starts above 10,000 feet—will be installed. All four Rolls-Royce Olympus 202/01 engines have been inspected and topped up with turbine oil.

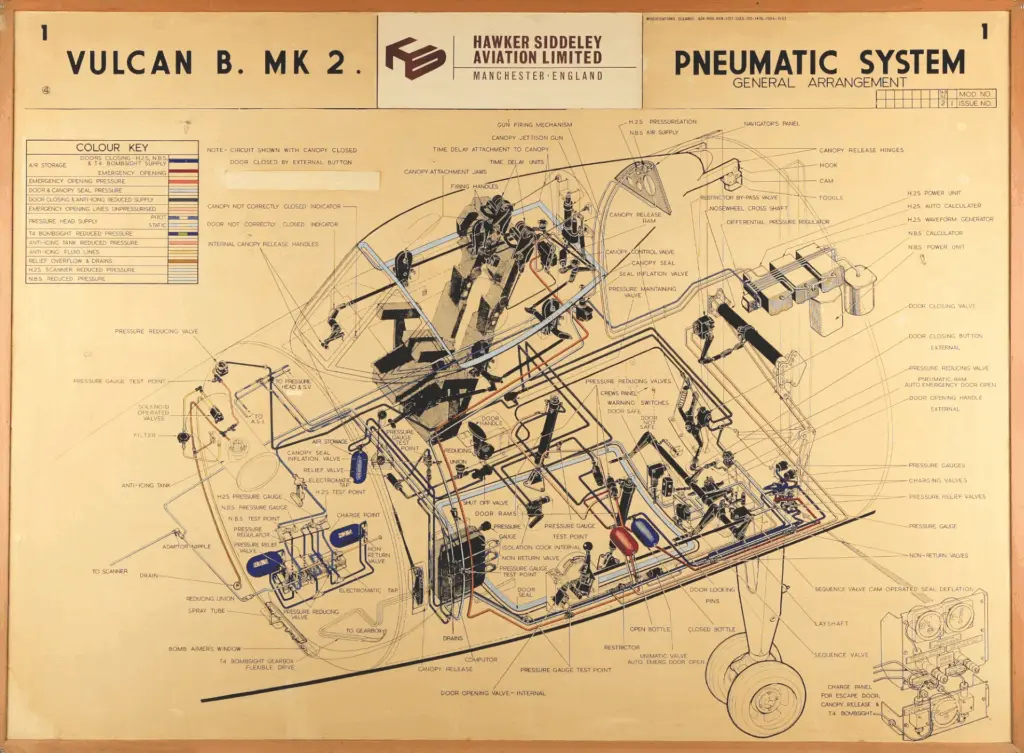

Pneumatics and Cabin Pressurisation The Vulcan’s pressurisation system, critical for high-altitude flight, has also been under review. With a service ceiling of 60,000 feet, the aircraft requires airtight seals on the canopy and entrance hatch to maintain cabin pressure. Investigations have revealed minor leaks, likely caused by canopy seal movement during nitrogen top-ups. To prevent further issues, the pneumatic line to the canopy seal has been temporarily isolated, and work is ongoing to locate and resolve the source of the leaks.

Ongoing Work and Community Support The past month has been particularly busy for the XH558 maintenance team, who have been working around the clock to complete these critical tasks. The Vulcan to the Sky Trust has thanked supporters for donations totaling £43,198, alongside £35,000 in matched funding from private donors. These contributions are vital to ensuring the aircraft remains safe during this critical period. While significant progress has been made, the Trust notes that additional funds are still required to secure XH558’s protection over the next 12 months. Every donation helps preserve one of Britain’s most iconic Cold War-era aircraft for future generations. For more information, visit www.vulcantothesky.org